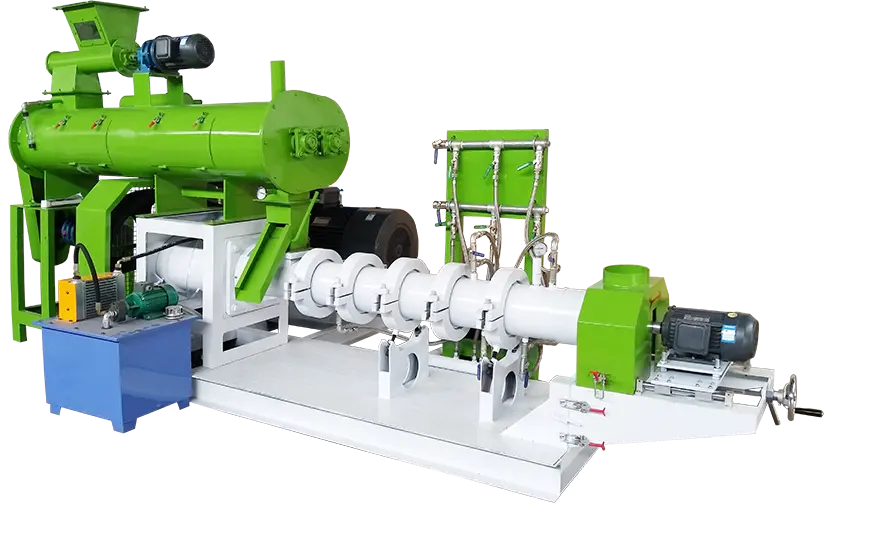

Wet Type Fish Feed Extruder

RICHI wet type fish feed extruder is a type of feed extruder with the conditioner, specially used for producing aquatic feed pellets and pet food pellets. Compared with the traditional process of using pellet mill to produce aquatic feed pellet, the extruded feed pellets produced by fish feed extruder are more popular in the market due to its higher quality, better maturity and other factors.

In the early years, the production of aquatic feed pellets mainly adopted the pelletizing process, but with the development and popularization of extrusion technology, more and more aquatic feed pellet processing plant began to use fish feed extruders to replace traditional feed pelletizers to produce aquatic feed pellet.

RICHI fish feed extruder is easy to operate and has advanced technical performance, which can fully meet the production needs of aquatic feed pellet mill. RICHI fish feed extruder is economical and affordable, so it is widely used in small and medium-sized aquatic feed processing plants and aquaculture farms.

Application of fish feed extruder

RICHI fish feed extruder can be used to process a variety of feed pellets

fish feed extruders can be used to extrude a variety of materials and are used in a variety of processing industries. However, the RICHI fish feed extruder is the extruder specially developed for the production of feed pellets. Therefore, the application of fish feed extruders we are talking about only represents the application of fish feed extruders in the feed pellet production industry.

RICHI fish feed extruder can be used to produce floating feed pellets, sinking feed pellets, slow sinking feed pellets for various fish, pet food pellets of different flavors to meet the feeding needs of pets, and some special types of aquatic feed pellets, such as fish bait feed pellets, ornamental fish feed pellets, fry feed pellets, etc.

Fish Feed fish feed extruder

According to the feeding needs of trout, sturgeon, catfish, herring and other fish, various types of extruded fish feed pellets can be produced, such as floating fish feed pellets, sinking fish feed pellets, etc.

Shrimp Feed fish feed extruder

The fish feed extruder is used to produce shrimp feed pellets, which have a high degree of maturity and can sink to the bottom of the water without deformation for a long time, reducing pollution to the aquaculture environment.

Pet Feed fish feed extruder

Pet food pellets of different shapes and flavors can be produced. Combined with the assistance of spraying equipment, the oil content of pet food pellets can be effectively increased to increase its palatability.

Advantages of using fish feed extruders for aquafeed production

RICHI fish feed extruder has many advantages in producing aquatic feed pellet

Aquatic feed pellet can also be produced using feed pellet mills, and the investment cost is relatively low. However, since the use of fish feed extruders to produce feed pellet has been promoted, more and more feed pellet mills have begun to choose to use fish feed extruder to produce aquatic feed pellets. So what are the advantages of using extrusion technology to produce aquatic feed pellets?

Can produce various types of aquatic feed pellets

fish feed extruder can be used to process various types of feed pellets, such as eel, catfish, carp, trout, shrimp, crab, etc. It can also be used to produce cat and dog food, pet food, feed pellets for ornamental aquatic organisms and other special feed pellets such as fish bait.

Improve feed conversion rate

The raw materials are processed at high temperature instantly, which increases the gelatinization degree in the raw materials to 80-99%. The increase in gelatinization degree is more conducive to the digestion and absorption of feed pellet by animals, especially aquatic animals.

Improve feed pellet stability in water

For aquatic feed pellet, stability in water, that is, the length of time it remains unchanged in water, is an important indicator for judging the quality of aquatic feed pellet. The extrusion method makes the stability of pellets in water reach 12 hours or even longer.

The density of feed pellets can be controlled

fish feed extruder can be used to produce floating feed, sinking feed pellet and slow sinking feed pellet, which is beneficial to the feed needs of animals in different water layers. Aquaculturists can also choose to feed different types of aquatic feed pellets according to their needs.

Extruded feed pellets have better mechanical properties

Extruded feed pellets are not easy to break. The extruded feed pellets produced by the RICHI fish feed extruder are not easy to break during transportation and feeding, thereby reducing the pollution of water and air caused by dust generated by feed crushing, and reducing feed waste.

Extruded feed pellets are cleaner and more hygienic

The high-temperature extrusion of the screw is equivalent to a pasteurization process. The harmful bacteria in the raw materials will be eliminated during the extrusion process, thereby reducing the impact of feed on aquatic animals and the pollution of water quality by harmful bacteria.

How to choose the fish feed extruder

High-quality fish feed extruder can produce high-quality extruded feed pellets

Through the above analysis of the advantages of using the fish feed extruder to produce extruded feed pellet, we can see that the quality of the fish feed extruder has a great influence on the quality of the final feed pellets, because only the high-quality fish feed extruder can produce extruded feed pellets that meet the above requirements. Therefore, when choosing the fish feed extruder, the following requirements need to be met:

The ripening rate of raw materials can be no less than 90%

Only raw materials that have reached this degree of maturity can produce feed pellets that are highly stable in water and resistant to corrosion.

Full modulation effect

Improve the degree of maturation of the material in the conditioner, reduce the mechanical energy intake of the screw extrusion part (which can increase production capacity), and advance the maturation area as much as possible to provide more space for subsequent cooling and pressure reduction.

Suitable aspect ratio

The reasonable length-to-diameter ratio of the fish feed extruder can ensure that the material is taken in with better mechanical energy and has enough space to cool down and reduce pressure.

Continuous production requirements

For commercial feed production, high-quality fish feed extruders must meet the commercial production requirements of long-term continuous production.

Working principle of fish feed extruder

Reasonable working process is the guarantee of finished feed pellet quality

The working principle of the fish feed extruder is completely different from that of the feed pelletizer. The fish feed extruder is mainly composed of feeding device, modulator, screw, extrusion cavity, molding template, cutter, parameter detection and control system, and driving power.

When the fish feed extruder is working, the material enters the barrel from the feed port and undergoes solid conveying, melting and homogenization processes in the screw, transforming the material from a loose state into a continuous plastic dough. It is then extruded and mixed in the extrusion chamber, and then passes through the forming template and cutter to form extruded feed pellets of a fixed size.

Feeding system

The forced feeder on the feeding screw allows a higher filling amount of the material to be achieved during the feeding process.

Stainless steel modulator

The modulator is located between the feeding device and the screw extrusion cavity. It adjusts the humidity and raises the temperature in the conditioning chamber. After stirring and mixing, the temperature and humidity of each material fraction are uniform.

Extrusion chamber

The screw extrusion chamber consists of two parts: the extrusion screw and the extrusion chamber barrel, which are the key components of the screw extrusion puffing machine.

Parameters of RICHI fish feed extruder

RICHI can provide various models of fish feed extruders with different capacitys

As the professional fish feed extruder manufacturer, RICHI can provide various models of fish feed extruders for customers to choose from.

The following table lists the parameters of some common fish feed extruders we produce. Of course, if the table does not include the fish feed extruder you need, you can contact us directly, because this is not all the fish feed extruders we can produce. We can provide you with the parameters and prices of the relevant fish feed extruders according to your specific needs and customize the appropriate fish feed extruder for you.

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | φ60 | 0.4 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | φ70 | 0.6 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | φ80 | 0.8 |

| DGP90-B | 0.50-0.60 | 37 | 1.1 | φ90 | 1.1 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | φ120 | 1.5 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | φ133 | 2.2 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | φ155 | 2.2-3.0 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | φ195 | 3.0-4.0 |

What can we offer?

As the professional fish feed extruder manufacturer, as long as you have the production needs of extruded feed pellets, we can meet all your needs, including fish feed extruder related information consultation, fish feed extruder equipment supply, complete set of extruded feed pellet production design and turnkey extruded feed pellet project construction.

1

Preliminary consultation: Provide you with consultation on the market, fish feed extruder machine, technology, raw materials, packaging, etc.

2

We can assist you with equipment selection, process design, and plant optimization layout. If necessary, we can provide door-to-door service.

3

According to the extruded feed pellets you need to produce, we adjust some designs of the fish feed extruder and customize the fish feed extruder that meets your production needs.

4

We can provide basic feed formulas for various types of aquatic feed pellets, pet food pellets, etc.

5

We will design the reasonable packing and transportation plan for you, and send technical personnel to install, debug and train personnel on site.

6

The equipment is under warranty for one year, with long-term discounts and spare parts supply.

Related feed production equipment

RICHI can provide all kinds of equipment needed for feed production

In the feed pellet production equipment industry, RICHI has nearly 30 years of experience. The feed production equipment, aquatic feed production equipment, feed extruders, etc. produced by RICHI are exported to more than 120 countries and regions around the world. In many countries and regions, there are feed mills and aquatic feed mills of different capacitys built by us.

Therefore, in addition to fish feed extruders, we can also provide a variety of aquatic feed production equipment used in the aquatic feed production process.

ABOUT RICHI MACHINERY

As the leading manufacturer of feed production equipment, RICHI provides high-quality feed manufacturing equipment and professional services for agriculture and aquaculture. Since its establishment in 1995, RICHI has continuously updated its feed production equipment to keep pace with the times. With advanced feed pellet production equipment processing technology, exquisite process technology, and strict inspection and testing systems, it strives to provide customers with excellent products.

We can provide customers with 1-100 ton feed mill turnkey projects and 1-50 ton fish feed mill turnkey projects, including the design of feed mill layout, the manufacture of complete set of feed production equipment, the installation of feed production equipment, and the training of workshop personnel, etc. Choosing a good partner can help you start the production of aquatic feed pellets more smoothly.