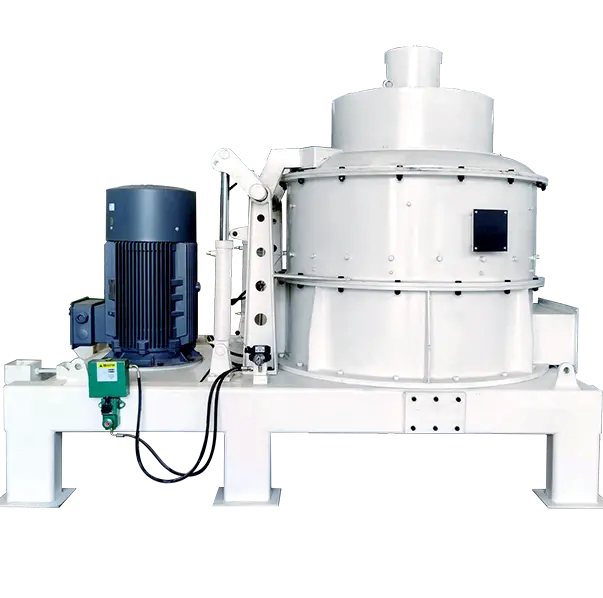

Ultrafine Grinder

The ultrafine grinder specially developed for the crushing of raw materials for aquatic feed. It can crush the raw materials to 60-80 mesh to meet the production needs of aquatic feed pellet.

Since aquatic animals have low food intake, short digestive tracts, and poor digestive capacity, the raw materials used to produce aquatic feeds require very low particle sizes to improve the digestibility of feeds by aquatic animals. Therefore, the production of aquatic feeds generally requires secondary grinding, which can be done with ordinary hammer mill and ultrafine grinders.

The ultrafine grinders we produce are widely used in the crushing of various aquatic feed raw materials and can well meet the production needs of aquatic feed.

+86 150 9316 3243

RICHI MACHINERY

How Does The Ultrafine Grinder Work?

The ultrafine grinder is a machine that pulverizes materials by the impact of hammers under the action of centrifugal force through the high-speed rotation of the pulverizing disk. The pulverized materials enter the pulverizing and grading chamber, and are graded by the balance of air power and centrifugal force through the rotating grading wheel. The separated coarse materials return to the pulverizing chamber from the bottom of the inner cavity of the guide cover and are repeatedly pulverized, so that the fine materials are sucked into the grading impeller and enter the pulverizing discharge chamber.

RICHI MACHINERY

Advantages of Ultrafine Grinder

- Integrated structure. The crushing chamber and the grading chamber are integrated, and crushing, breaking and separation are completed simultaneously in the crushing process.

- Hydraulic opening device. Designed with a hydraulic opening device, the crushing chamber can be opened quickly for easy inspection and maintenance.

- Hammer head. Unique hammer head installation method makes it more convenient and quick to replace the hammer head.

- Material crushing fineness can be easily controlled by adjusting air flow velocity, feeding velocity and classifying impeller speed.

- Unique arch-breaking feeding device prevents materials from arching during feeding.

- Special carbide hammer head has high wear resistance, low temperature rise of crushed materials and less water loss.

RICHI MACHINERY

Ultrafine Grinder Parameters

The following are the parameters of some common models of ultrafine grinders we produce. If you want to know more detailed information about ultrafine grinders, please contact us immediately. We will customize the appropriate ultrafine grinders according to the needs of each customer.

| Model | SWFL90 | SWFL110 | SWFL130 | SWFL150 | SWFL170 |

| Main Power (kw) | 90 | 110 | 132 | 160 | 220 |

| Classifying wheel power(kw) | 7.5 | 7.5 | 11 | 15 | 18.5 |

| Feeder power(kw) | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Capacity (t/h) | 1-2 | 3-4 | 4-5 | 5-8 | 8-12 |

RICHI MACHINERY

Different Types of Ultrafine Grinder

SWFL90 Ultrafine Grinder

Capacity:

1-2 T/H

Main Power:

90 kw

SWFL110 Ultrafine Grinder

Capacity:

3-4 T/H

Main Power:

110 kw

SWFL130 Ultrafine Grinder

Capacity:

4-5 T/H

Main Power:

132 kw

SWFL150 Ultrafine Grinder

Capacity:

5-8 T/H

Main Power:

160 kw

RICHI MACHINERY

Ultrafine Grinder Can Be Customized

The above are just some of the models and parameters of the ultrafine grinders we produce. Ultrafine grinders is an important process in the production of aquatic feed that can improve the quality of aquatic feed. We can customize the ultrafine grinders for you according to your needs, such as the output of the ultrafine grinders, the pulverization of special raw materials, etc.

If you want to know more about ultrafine grinders , please contact us directly!

RICHI MACHINERY

Why do we need to use ultrafine grinder to produce aquatic feed?

Ultrafine grinding is a very important process in the production of aquatic feed. For some aquatic feed producers, the correct configuration of ultrafine grinding machine can directly improve the quality of aquatic feed pellet.

The main reasons why ultrafine grinders are used in the production of aquatic feed are as follows:

01 Increase the particle size of the particles to improve the utilization rate of feed by aquatic animals.

Aquatic organisms, such as fish, shrimp, crabs, etc., are naturally characterized by short digestive tracts and poor digestion ability. Therefore, the raw materials used to produce aquatic feed require a very low particle size, so that aquatic organisms can improve the digestibility of feed when eating;

02 Increase the particle size of the particles and improve the mixing uniformity of the raw materials.

The particle size of the raw materials directly affects the mixing uniformity. Due to the low food intake of aquatic animals, the feed raw materials are required to achieve a higher mixing uniformity. For example, for the raw materials used to produce shrimp feed, the 60-mesh sieve must contain less than 5%, so a micro-crushing process must be used;

03 It affects the subsequent granulation and extrusion processes, as well as the quality of feed pellets.

For feed made from grains, the finer the grain feed is ground, the more fully its starch particles are gelatinized after steam conditioning, and the more uniform the moisture content, making the quality of the finished feed pellets better.

RICHI MACHINERY

Application of Ultrafine Grinder

The ultrafine grinder produced by RICHI can be used not only for pulverizing in the feed industry, but also for ultrafine grinding in the food industry, pharmaceutical industry, chemical industry, ceramic industry and other industries, especially for fibrous and high-toughness materials. Therefore, if you have ultrafine grinding needs in various industries, you can contact us directly.

Ultrafine Grinder in Fish Feed Mill

Provide fish feed ultrafine grinder and complete set of fish feed production machine and turnkey fish feed production line.

Ultrafine Grinder in Shrimp Feed Pellet Mill

Provide 1-12 tons per hour ultrafinegrinder for shrimp feed raw material grinding, suitable for medium and large shrimp feed plant.

Ultrafine Grinder in Pharmaceutical Industry

It can meet the fine grinding needs of the pharmaceutical industry and produce ultra-fine pharmaceutical powder.

Can’t Find The Ultrafine Grinder You Want?

Contact Us To Customize For You!

RICHI MACHINERY

Other Related Crushing Equipment

RICHI is professional manufacturer of feed production equipment and pellet production equipment. In addition to providing customers with ultrafine grinders, we can also provide other crushing equipment needed in the feed production process or pellet production process, such as hammer mills, grass crusher, wood chippers, and small-capacity grass crusher, etc.

Hammer Mill

1-25 tons per hour hammer mill can be used to crush various granular raw materials, such as corn, wheat, sorghum, etc. It is a commonly used crushing equipment in feed production.

Wood Chipper

Used for wood processing and treatment, logs can be cut into thin wood chips of about 3 cm. It is often used in the wood pre-treatment stage in the production process of wood chip pellets.

Grass Crusher

In order to crush raw materials such as forage grass and straw, RICHI has developed a special forage crusher equipped with a forced feeder, a larger feeding port and a knot arch device.

Small Capacity Grass Crusher

It is suitable for small-scale forage crushing production with capacity of less than 1 t/h. It does not have a forced feeder and is economical and applicable for users with small-scale crushing needs.

RICHI MACHINERY

You May Also Like

Ultrafine grinder is an important equipment for aquatic feed production line and pet food production line. If you want to produce high-end aquatic feed, ultrafine grinder is an indispensable equipment. The feed production line composed of ultrafine grinder and mixer, cooler, dryer, sprayer, packang equipment, etc. can produce aquatic feed that meets the breeding needs of all farmers.

In addition to ultrafine grinder, we can provide custom plan designs and turnkey feed production projects for aquaculture farms and feed production plants.