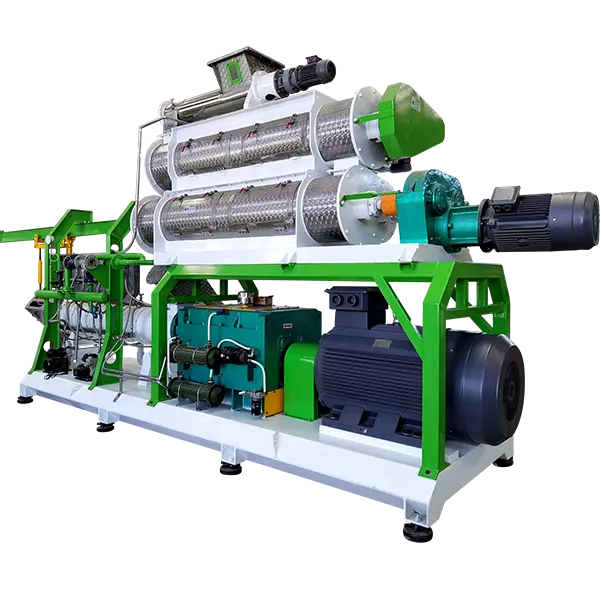

Twin Screw Extruder

The SPHS series twin screw extruder newly developed by RICHI can produce high-end expanded aquatic feed pellets to meet the feeding needs of the aquaculture industry.

Capacity: 1-12 T/H

Twin screw extruder from RCIHI

In recent years, with the rapid development of aquaculture, twin screw extruder machine have been increasingly used in various aquatic feed pellet mills and large aquatic feed farming factories.

As the professional twin screw extruder manufacturer, RICHI provides high-quality twin screw extruders to many customers with thirty years of mature industry experience.

The twin screw extruder machine produced by RICHI is easy to operate and can process materials with high oil and water content. It can also process raw materials with added fresh meat slurry or meat paste, which can meet the feed needs of factory aquaculture.

Application of twin screw extruder

RICHI twin screw extruder machine consists of screw feeder, regulator and an extrusion system. The extrusion system extrude the material under the action of the screw, and the formed particles are extruded from the mold, and then cut into finished feed pellets of the required length by the cutter, which can meet the production needs of various types of feed, such as various fish feed pellet twin screw extruders, shrimp feed pellet twin screw extruders, dog food twin screw extruders, cat feed twin screw extruders, etc.

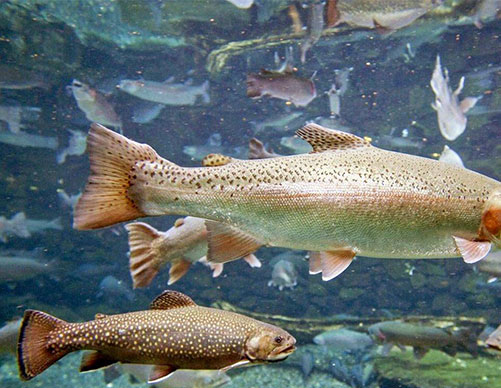

Twin screw extruder machine for fish feed

Various fish feed pellets can be produced according to the feeding needs of fish, such as trout feed pellets, sturgeon feed pellets, herring feed pellets, etc.

Twin screw extruder machine for shrimp feed

RICHI twin screw extruder can produce high-end sinking shrimp feed pellets to meet the feeding needs of shrimp farms.

Twin screw extruder machine for Pet food

Twin screw extruders, sprayers, drying machines, etc. can work together to produce pet food of various flavors to meet the purchasing needs of pet owners.

Twin screw extruder models and parameters

Common twin screw extruders include 1 ton per hour twin screw extruder, 5 tons per hour twin-screw extruder, etc. In addition to the common twin-screw extruder models and parameters, we can also customize twin screw feed extruders for customers according to their production needs.

| Model | Main Power(kw) | Dia. of Screw(mm) | Capacity(t/h) | Matching feeder model-power | Matching differential conditioner model-power |

| SPHS120*2 | 75 | 120 | 1~2 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS120*2 (6.6*1.6*4M 6T) | 90 | 120 | 3~4 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS150*2 | 160 | 150 | 4~5 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS 150*2 (8*2*4.3M 8T ) | 200 | 150 | 6~7 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS185*2 | 315 | 185 | 8~10 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

| SPHS185*2 | 355 | 185 | 10~12 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

1-2 t/h twin screw extruder

It is suitable for feed production needs of small feed mills and aquaculture plants.

3-4 t/h twin screw extruder machine

It can produce 1-6mm fish feed pellets and pet feed pellets.

5-6 t/h twin screw feed extruder

Best-selling twin screw extruder, customers often ask us for twin screw extruder with this output.

7-8 t/h twin screw extruder for sale

Custom designed twin screw extruders can process a variety of raw materials.

9-10 t/h twin screw extruder machine

Provide turnkey fish feed production plant and turnkey pet feed pellet mill.

11-12 t/h twin screw extruder

Suitable for medium or large aquatic feed pellet mills, as well as large aquaculture processing plants.

Customized Twin Screw Extruder

Different models of twin screw extruder machine can meet the production needs of different feed pellet mills. These are just the conventional models of twin screw extruders we produce. Considering some customers with special needs, such as producing aquatic feed pellets with higher oil content and producing smaller fish feed pellets, we can customize unique twin screw extruders for customers according to their needs.

As for the screw extruder price, the twin-screw extruder price with different capacitys, different models, and twin screw extruders with different modulators are all different. So if you want to know the twin-screw extruder price , you can first send us your needs through online messages or emails, and we will send you relevant commercial quotations according to your needs.

Features of twin screw extruder

Can produce various types of feed pellets

RICHI special twin screw feed extruder has good equipment quality and high production efficiency, and is welcomed by many aquatic feed factories.

Twin screw extruder machine can be used to produce various types of feed pellet, such as floating feed pellet, sinking feed pellet, slow sinking feed pellet, etc., which are suitable for the growth needs of various fish.

Rich variety of raw materials

It can process raw materials with high oil and high moisture content, so that the finished feed pellets contain higher oil content, meeting the growth and development needs of fish and pets.

Reduce energy consumption

The newly developed twin screw extruder machine makes full use of steam thermal energy instead of mechanical energy, which reduces electricity consumption per ton while increasing capacity.

High standard accessories

All accessories adopt international advanced standards, such as SKF bearings, Siemens motor and spring steel cutters, which effectively improve the stability of equipment operation and reduce noise.

Fully automatic control

The entire twin screw feed extruder machine adopts a fully automatic control system, and one person can operate multiple machines, which can improve production efficiency and reduce costs.

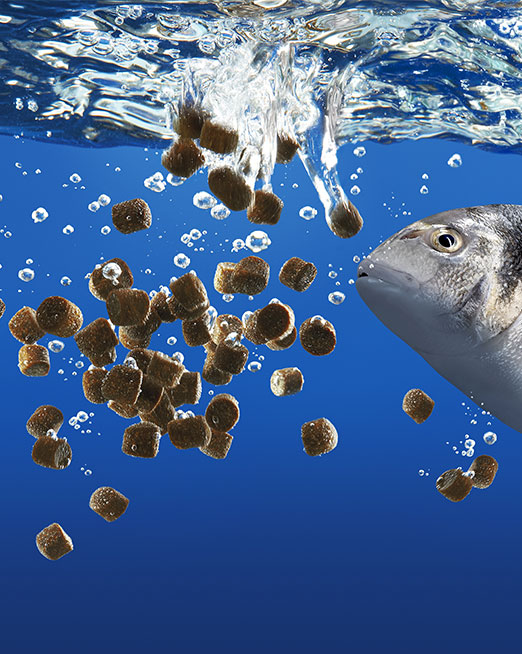

Twin screw extruder finished pellets

RICHI twin screw extruder machine can not only produce cylindrical feed pellets, but also produce feed pellets in various shapes such as round, triangular, and five-pointed star shapes to meet the feeding needs of various fish and pets.

Extruded feed is loved by more and more farmers due to its good water resistance, easy digestion and absorption, and good taste.

The difference between extruder and pelletizer

— Richi Machinery —

Both twin screw extruder machine and feed pelletizer can be used to produce aquatic feed pellet, but compared to pellet mills, twin screw extruder machines have the following characteristics:

1. Twin screw extruder machine can process raw materials with high oil and high moisture content.

2. Twin-screw extruders can produce floating feed pellet, sinking feed pellet, slow-sinking feed pellet, etc. Feed pelletizer can only be used to produce sinking feed pellet.

3. The working principles are different. The twin screw extruder machine uses the puffing extrusion principle, and the granulator uses the pellet pressing principle.

Can the twin screw extruder be used to make cattle and sheep feed?

Of course, in addition to producing aquatic feed pellet and pet feed, twin screw extruder machine can also be used to produce cattle feed pellet, sheep feed pellet and other animal feed pellet. However, if you want to produce cattle feed pellet, sheep feed pellet and other poultry feed pellet, we recommend that you use the feed pelletizer, because using feed pelletizer to produce cattle feed, sheep feed, etc. is more cost-effective.

For example, if the twin screw extruder machine with power of 55 kw is used to produce cattle feed pellet, sheep feed pellet, etc., the capacity is 500 kilograms. If the feed pelletizer is used to produce animal feed pellet, then 1 ton of feed pellets per hour is produced, and the power of the feed pelletizer is less than 200,000 kilograms. Therefore, it is more cost-effective to use feed pelletizer than twin screw extruder machine to produce cattle feed pellet and sheep feed pellets.

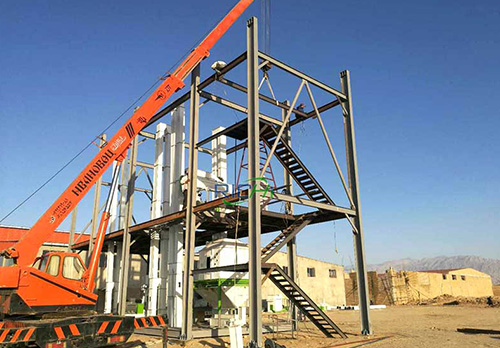

twin screw extruder machine in feed mill

— Richi Machinery —

RICHI twin screw extruder machine can be applied to all kinds of feed production plants. We can not only provide customized twin screw extruders, but also provide complete aquatic feed production lines and turnkey fish feed production plants.

If you want to use a complete aquatic feed production line to produce aquatic feed pellet, in addition to the twin screw extruder machine , you also need pulverizer, mixer, sprayer, cooler, drying machine, packing equipment, etc.

The main equipment used in the fish feed production line:

Receiving and handling of raw materials

First crushing and first mixing

Second crushing

Second mixing

Extrusion

Drying

Spraying

Cooling

Packing