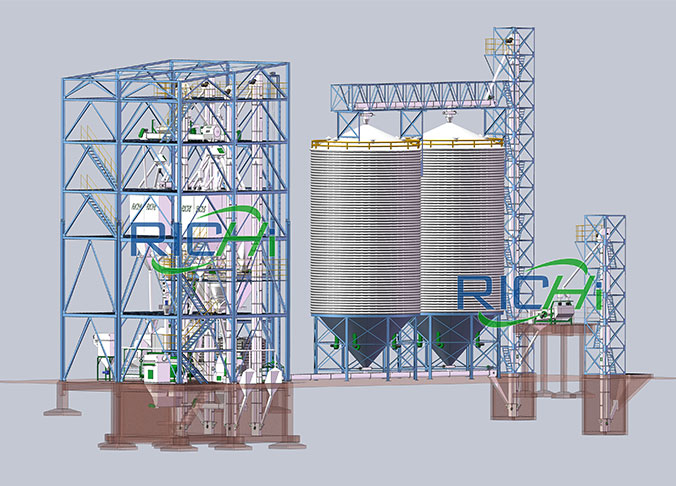

Customized Turnkey Fish Feed Production Project

Sinking Fish Feed Production line

0.5-50 t/hour sinking fish feed production line solutions.

We can provide a full set of sinking fish feed production machine and turnkey projects sinking fish feed production line.

Introduction of Sinking Fish Feed line

— Richi Machinery —

Introduction

As world-leading sinking fish feed pellet line manufacturer, we have been deeply involved in the field of sinking fish feed production for nearly 30 years. We can provide you with a complete set of sinking fish feed machine, turnkey sinking fish feed production line projects, and customized solutions for fish feed pellet mill.

Our experience and expertise enables us to provide you with comprehensive advice and hassle-free service throughout your sinking fish feed production project.

Application : Can produce fish feed for salmon, sturgeon, bream, sea bass, etc.

Raw materials: Fish meal, soybean meal, soybean cake, peanut cake, wheat bran, bran, flour, shrimp head powder, yeast powder, soybean lecithin, clam shell powder, etc.

0.5-50

Capacity(ton/hour)

0.6-8

Feed pellet size(mm)

Advantages of floating fish feed mill

Customized Design

The sinking fish feed pellet mill can be customized according to the size of the plant and specific needs.

Modular Design

The entire process of the fish feed production line is modular in design, and the production sections can be increased or decreased according to the needs.

Automation

Fully automated and manual production processes can be selected according to demand.

Pelleting process and extrusion process

Based on the raw materials, local demand, quality of finished feed pellets, etc., you can choose the pelletizing process or the extrusion process.

One line for multiple uses

It can be used not only to produce sinking fish feed, but also to produce various floating fish feed, shrimp feed, poultry feed, livestock feed and so on.

Turnkey Projects

We provide full-process services from the design of sinking fish feed production line to the production and installation of equipment.

Capacity of sinking fish feed production line

RICHI can build sinking fish feed production lines and sinking fish feed pellet mill with different capacitys to meet the production needs of customers in different regions.

The more common one is the turnkey solution of 0.5-50 tons sinking fish feed production line, but if you have any special needs in terms of output, please contact us directly!

1 t/h sinking fish feed pellet mill

Small sinking fish feed pellet mill, which can meet the feeding needs of large fish farms and the investment needs of small fish feed pellet mill.

5 t/h sinking fish feed pellet mill plant

According to the development of local aquaculture industry and the market demand for aquatic feed, it can meet the needs of investors who have investment needs in medium or large aquatic feed pellet mill.

0.5 t/h

1-2 t/h

3-5 t/h

10 t/h

10-18 t/h

Finished floating feed pellet

— Richi Machinery —

The fish feed pellet produced by the sinking fish feed production line we design and the sinking fish feed pellet mill we build can meet the feeding needs of salmon, sturgeon, bream, sea bass, etc.

Salmon

Sturgeon

Cichlids

Seabass

Catfish

Ornamental fish

sinking fish feed pellet process

— Richi Machinery —

RICHI has always been at the forefront of fish feed pelleting technology and attaches great importance to the innovation of sinking feed production technology.

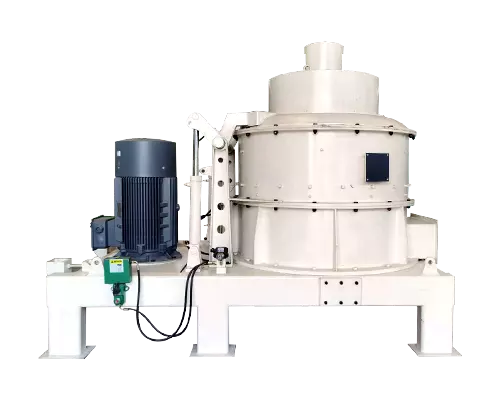

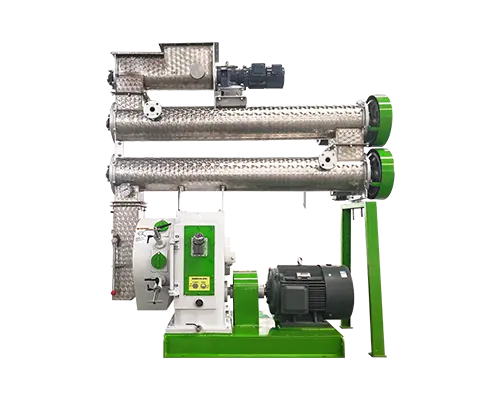

There are two main processes for producing sinking fish feed pellet: using a pellet mill to produce sinking fish feed pellets and using a feed extruder to produce extruded fish feed pellets.

Among them, the method of using pelleting process to produce sinking fish feed pellet is still a commonly used process by many sinking fish feed manufacturers. However, with the development of fish farming industry and the continuous improvement of sinking fish feed production technology, many places have begun to use feed extruders to produce sinking fish feed pellet.

As a well-known feed machinery manufacturer, no matter which process customers choose to use to produce sinking fish feed pellet, RICHI can provide the best solution and a full set of fish feed pellet machine.

Pelleting process flow: Raw material receiving and cleaning – coarse crushing – first mixing – second crushing – second mixing – pelleting – drying – spraying – cooling – screening – packing

Extrusion process flow: Raw material receiving and cleaning – coarse crushing – first mixing – second crushing – second mixing – extrusion – drying – spraying – cooling – screening – packing

Sinking Fish Production Feed line

This is the standard process flow for sinking feed pellet, but not every customer needs to use all the work sections. Each work section in our entire feed production line is modularly designed, and we can add or reduce work sections according to specific needs; and the equipment in each work section will also be adjusted according to the needs of raw materials, capacity, etc.

RICHI’s Footprints

— Richi Machinery —

RICHI has footprints in more than 120 countries and regions around the world, serving global customers with high-end quality; with more than 200 classic cases, it has become a leader in the field of feed making machine.

2-3 t/h fish and shrimp feed production line in Ecuador

Feed types: Floating fish feed, sinking fish feed and shrimp feed

Features of sinking fish feed production line:

The aquatic feed factory was invested and built by the customer. In order to occupy a larger share in the aquatic feed market, the entire feed production line is relatively complete. Because different raw materials are needed to produce different aquatic feed pellet, and the production line is equipped with feed extruders and pelletizers, various types of aquatic feeds can be obtained.

5 t/h fish feed pellet mill in Uzbekistan

Feed types: Mainly used as sinking fish feed pellet

Features of fish feed pellet mill:

The feed production project is located in India. In order to meet the loThis project is located in Uzbekistan. It is a fully automatic fish feed production line. The entire feed production line, from the receipt of raw materials to the packaging of finished pellets, is all automated. The customer found our company through his friend. After discussing the design of the fish feed pellet line with our engineers, he decided to choose us as his partner.

1.5-2 t/h fish and shrimp feed production line in Iran

Feed types: Shrimp feed, floating fish feed and sinking feed

Features of fish and shrimp feed pellet line:

Our Iranian customers purchased a compound feed production line from us that can produce both fish feed pellet and shrimp feed pellet.

The height of a standard fish feed pellet mill is more than 20 meters, but because the location of the fish feed production project has certain requirements for the height of the feed mill, we finally changed the height of the fish feed production line plant to 8 meters according to the customer’s requirements.

3-4 t/h fish and poultry feed pellet mill in India

Feed types: Mainly sinking feed, sinking fish feed, sinking shrimp feed

Features of feed pellet mill:

The feed production project is located in India. In order to meet the local aquaculture needs, the customer invested in building an aquatic feed production plant, which is mainly used to produce sinking feed to meet the feeding needs of fish and shrimp.

Because it was a special period, the customer did not come to our factory, but we had a video conference and visited our factory and equipment via video.

Customized sinking fish feed production line design

— Richi Machinery —

Customized solutions can help different customers achieve their unique business needs, improve efficiency and reduce costs.

All of RICHI’s fish feed production lines are custom designed. We can tailor professional fish feed pellet mill for customers based on different raw materials, site size and height restrictions, automation requirements, and production needs.

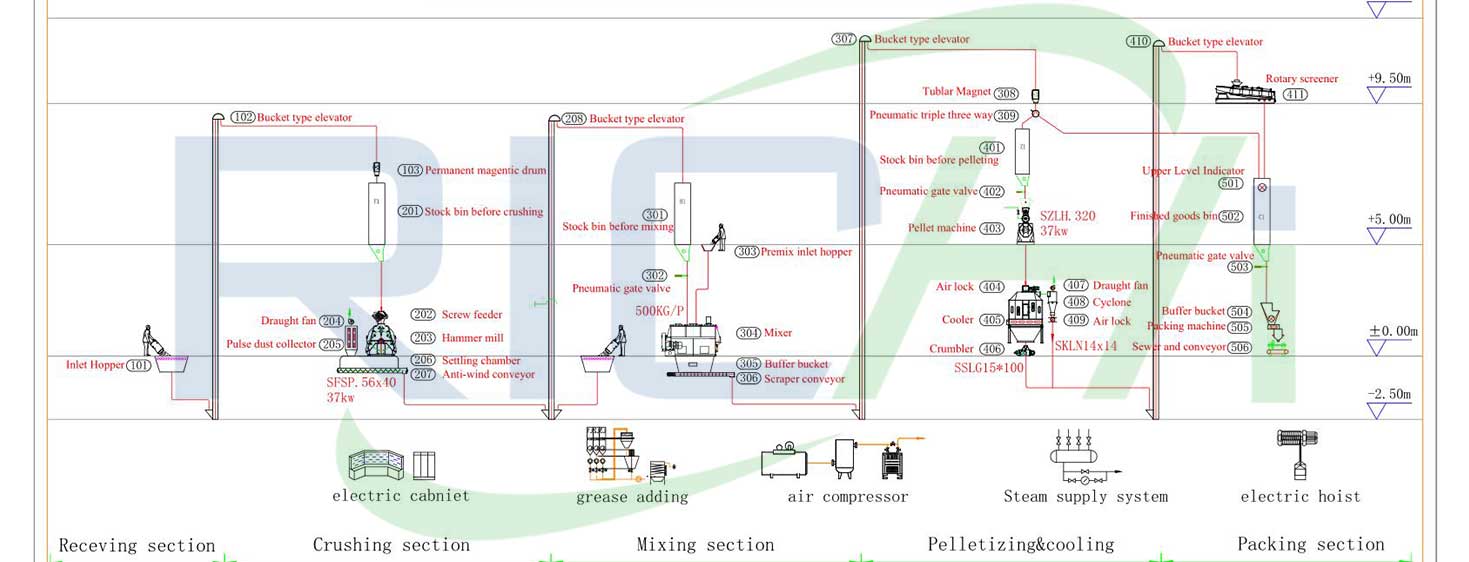

2 t/ hour sinking fish feed production line

Type of Feed Produced: Mainly used to produce sinking aquatic feed pellet

Process flow: Receving section – Crushing section – Mixing section – Pelletizing&cooling – Packing section

Main equipment used: Hammer mill,Pemanent magentie drum,Mixer,Pellet machine,Cooler, Rotary screener, Packing machine

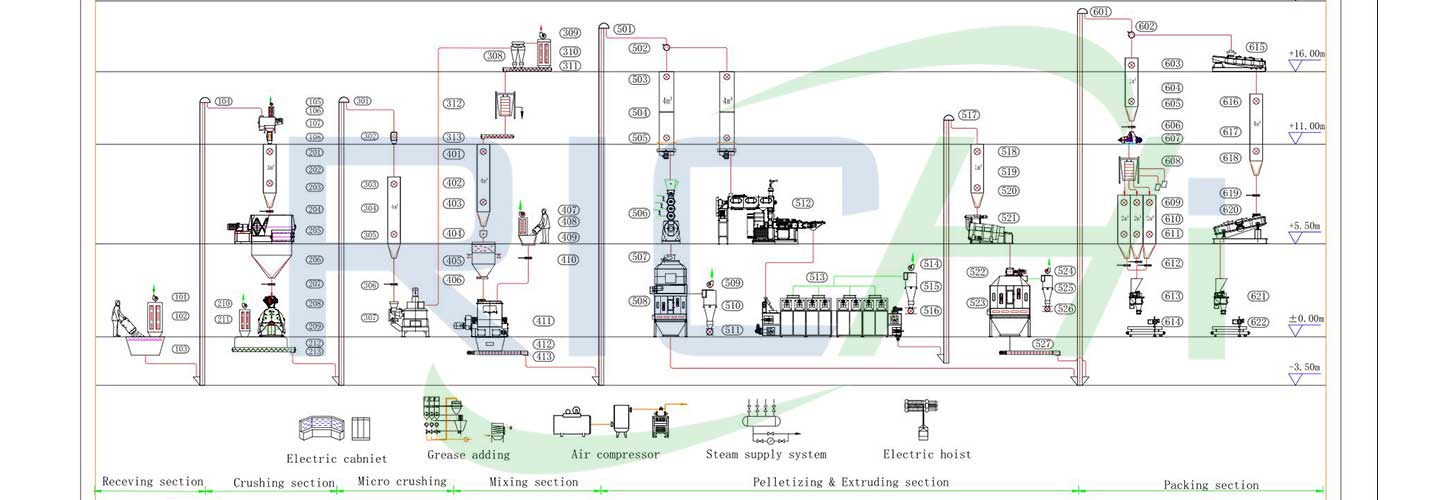

5 t/hour fish feed pellet production line (extrusion process)

Type of Feed Produced: Mainly used to produce sinking fish feed pellets

Process flow: receving section – crushing section – batching & mixing section – micro crushing section – mixing section – puffing & drying section(This fish feed production line design uses extrusion technology to produce fish sinking feed pellets) – packing section

Main equipment used: Hammer mill,Silo,Batching scale, Feed mixer,Ultrafine grinder,High Plansifter, Feed Extruder, Belt dryer,Screening equipment, Packing scale

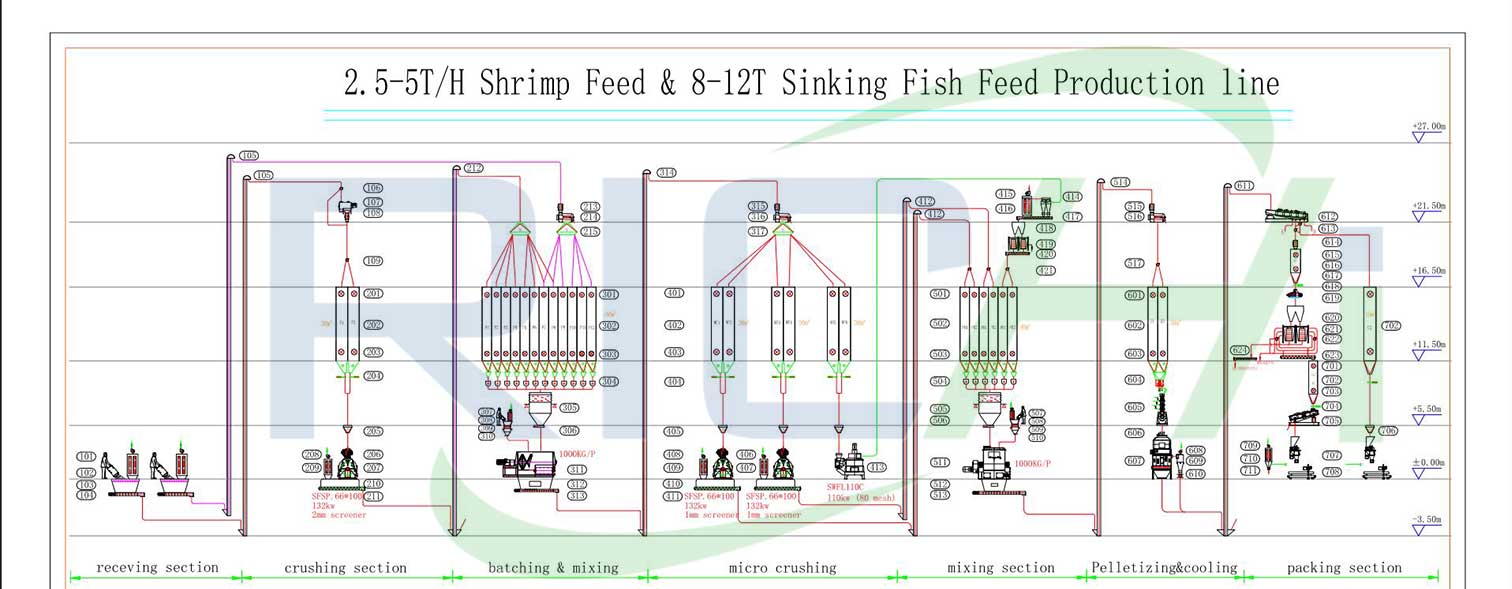

2.5-5 t/h shrimp feed pellet & 8-12 t/h sinking fish feed production line

Type of Feed Produced: Sinking fish feed pellet, shrimp feed pellet

Process flow: Raw material receiving system – first crushing system – batching and first mixing system – second crushing system – second mixing system – granulation system – cooling system – screening system – packing system

Main equipment used: Hammer mill, feed mixer, ultrafine grinder, high square sieve, fish feed pelletizer, powder cleaning sieve, vibrating screen, packing equipment

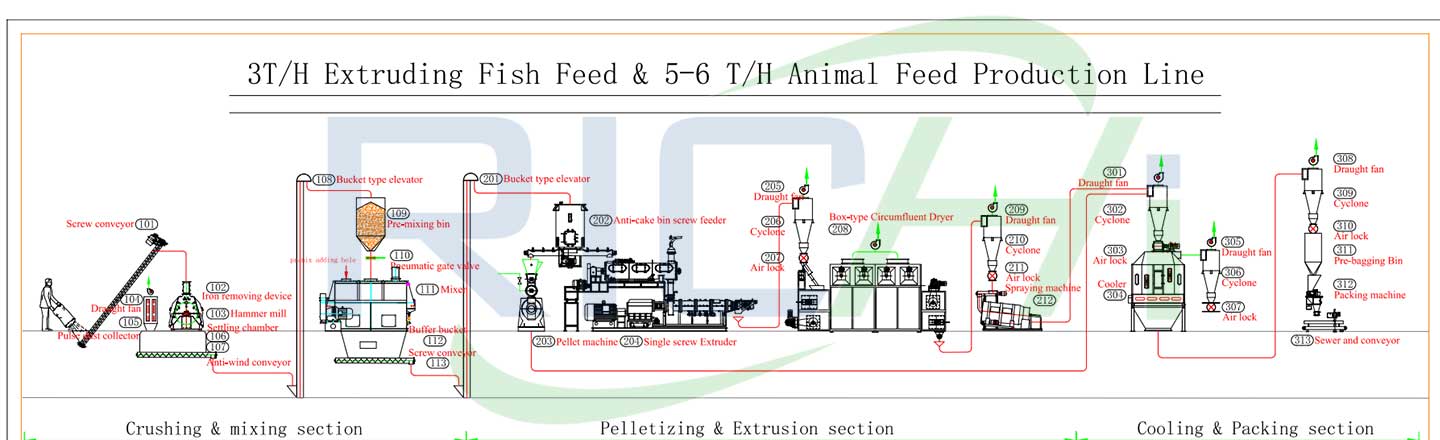

3-4 t/h fish feed pellet and 5-6 t/h poultry feed production line

Type of Feed Produced: Sinking fish feed pellet, poultry feed pellets

Process flow: Crushing & mixing section – Pelletizing &Extrusion section – Cooling & Packing section

Main equipment used: Hammer mill,Mixer, Pellet machine,Single serew Extruder, Box-type Circumfluent Dryer, Spraying machine, Cooler, Packing machine

Frequently Asked Questions

what are the benefits of using sinking feed to feed fish?

Meet the feeding needs of bottom aquatic organisms. After the sinking feed pellet sink to the bottom of the water, bottom aquatic organisms such as catfish and loaches living on the bottom of the water can eat directly on the bottom of the water;

Nutritionally balanced. The feed pellets produced using a specific formula are nutritious and can meet the normal growth needs of fish.

Reduce waste. Compared with the method of directly spreading the raw materials into the water, feeding the fish with pellets can greatly reduce waste and reduce water pollution.

can the feed pelletizer used to produce sinking aquafeed be used directly to produce shrimp feed?

Both the feed pelletizer with double-layer modulator and the feed pelletizer with triple-layer modulator can be used to produce sinking fish feed, but if you want to produce shrimp feed, you can only use the feed pelletizer with triple-layer modulator because the degree of maturation is relatively high when producing shrimp feed pellet.

So if you want to produce both sinking fish feed and shrimp feed, you can directly equip the pellet mill with a three-layer modulator. Of course, you can also equip a pellet mill with a double-layer modulator and a pellet mill with a three-layer modulator according to the output and other requirements.

If I want to invest in a small feed mill, such as 1t/h fish feed mill, do I also need all the equipment mentioned above?

Of course not. First of all, the above is a standard process flow for fish feed production. Each process section is modularly designed and can be increased or decreased according to the specific needs of each customer.

Secondly, the equipment equipped in each work section will also be adjusted according to the customer’s raw material types and capacity. For example, some customers may not need to use ultra-fine grinders, and ordinary grinders can meet production needs.

In addition, all our solutions are customized. All processes of the entire feed production and the required equipment will be customized and produced according to the actual situation of each customer.

If I want to produce both floating fish feed and sinking fish feed pellet, do I need to purchase two feed production lines to meet my production needs?

No. Some feed mills only produce a single type of feed, such as sinking fish feed, floating fish feed, shrimp feed, chicken feed, cattle feed, etc.; there are also a large number of feed mills that produce multiple types of feed at the same time, which is what we call a compound feed pellet mill.

A compound feed pellet mill does not need to be equipped with two completely different feed production lines, because many equipment can be shared, such as grinders, mixers, coolers, packing machine, etc., as well as auxiliary equipment on the feed production line, can all be shared.

Therefore, you only need to equip different feed pellet machines, feed extruders, etc. according to specific production needs to achieve the purpose of producing a variety of feeds, without the need to purchase two complete feed production lines.