Sinking Fish

Feed Machine

High Quality Sinking Fish Feed Machine

Customized Sinking Fish Feed Machine Solutions

Sinking fish Feed Machine

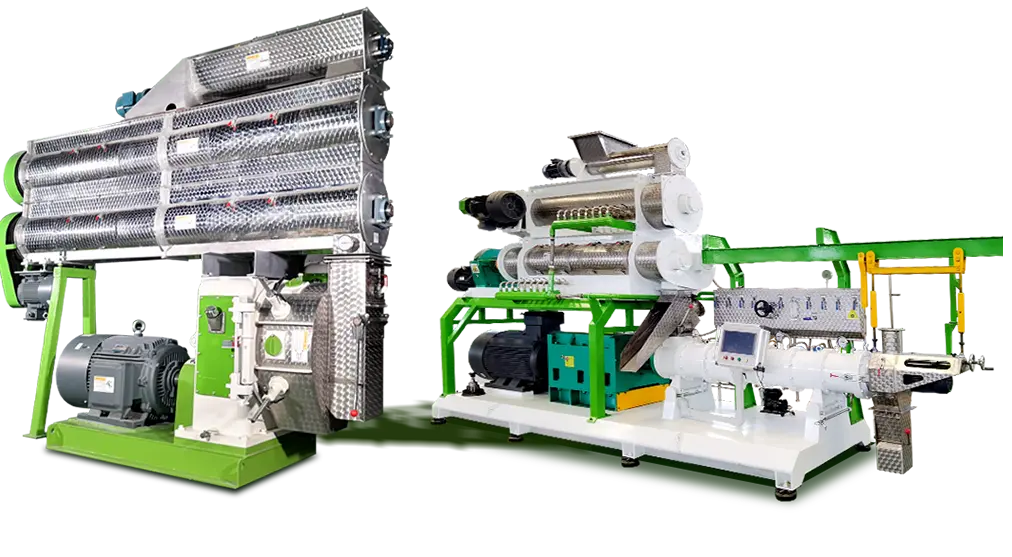

fish feed pellet machine

The sinking fish feed machine can be widely used to produce feed pellets that meet the growth needs of various fish, shrimps, crabs and other aquatic organisms. There are two main types of equipment currently used to produce fish feed, one is the fish feed pellet machine with double or triple layer conditioner.

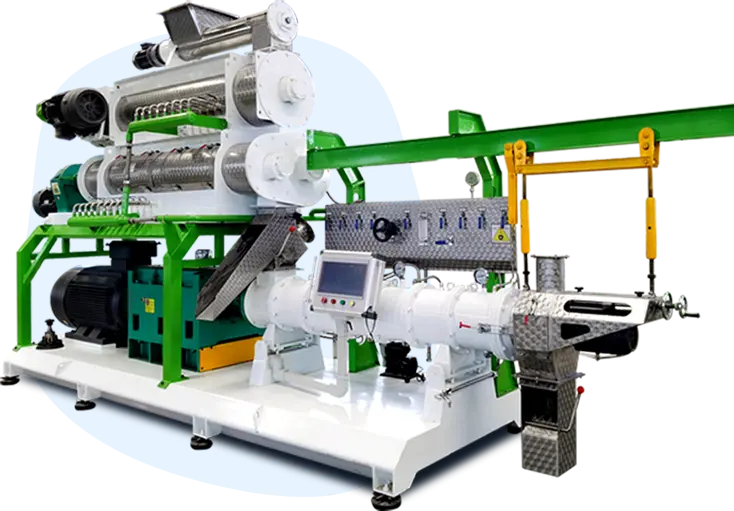

fish feed extruder machine

The other is fish feed extruder machine, which uses extrusion process to produce sinking fish feed pellet.

Depending on the type of raw materials, the capacity of the fish feed production project, and specific investment requirements, you can choose to use a fish feed pellet machine or fish feed extruder machine to produce aquatic feed pellets that meet your requirements.

Fish feed pellet machine

— Richi Machinery —

RICHI SZLH series fish feed pellet machine is mainly used for the production of animal feed pellets for aquatic products, livestock and poultry, ruminants, etc. It has humanized design and simple operation. It is currently widely used in various animal feed and aquatic feed pellet mill, as well as aquaculture farms and animal breeding plants.

Fish feed pellet machine price: $7,000-$100,000

Features of fish feed pellet machine:

Casting Manufacturing

The active transmission box is a casting with high hardness, large load-bearing capacity and long service life.

Stainless steel

The main parts such as modulator and ring die are made of stainless steel, which is corrosion-resistant.

Powder spraying process

The appearance adopts powder spraying process, first spraying powder, then electric baking, and then drying.

gear transmission

The main transmission system adopts gear transmission, which has high efficiency and high capacity

Siemens motor

The main motor uses a Siemens motor.

Inverter motor

The feeding system adopts stepless frequency conversion motor control, which is convenient for adjusting the feeding speed.

Fish feed pellet machine parameters

| model | Output (t/h) | Main motor power (kw) | Feeder power (kw) | Conditioner power (kw) | Ring die diameter (mm) |

| SZLH250 | 1~2 | 22 | 1.1 | 1.5 | 250 |

| SZLH320 | 3~4 | 37 | 1.5 | 2.2 | 320 |

| SZLH350 | 5~7 | 55 | 1.5 | 3 | 350 |

| SZLH420 | 8~12 | 110 | 1.5 | 7.5 | 420 |

| SZLH508 | 10~18 | 160 | 2.2 | 11 | 508 |

| SZLH558 | 15~25 | 180/200 | 2.2 | 11 | 558 |

| SZLH678 | 20~30 | 220/250 | 2.2 | 11 | 673 |

Fish feed extruder machine

— Richi Machinery —

RICHI fish feed extruder machiner is mainly composed of screw feeder, modulator and extrusion system, which is used to produce high-grade sinking or floating aquatic feed to meet the demand for fish feed in factory fish farming.

Fish feed extruder machine price: $2,000-$100,000

Features of fish feed extruder machine:

Screw

The screw is made of new materials and processed using the latest processing technology to extend the service life of the screw.

Extrusion chamber

The extrusion chamber adopts a bimetallic expansion chamber sleeve to reduce wear and ensure long-term stable operation of the equipment.

Mobile cutter stand

The cutting part adopts movable cutter seat, and the blade is made of spring steel, which fits the template better.

Saturated hot steam

Injecting saturated hot steam into the modulator and using steam heating can significantly reduce costs and increase capacity.

automatic control

The whole equipment adopts a fully automatic control system to improve production efficiency.

Siemens motor

The main motor adopts Siemens motor.

Fish feed extruder machine parameters

| Model | Main Power(kw) | Dia. of Screw(mm) | Capacity(t/h) | Matching feeder model-power | Matching differential conditioner model-power |

| SPHS120*2 | 75 | 120 | 1~2 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS120*2 (6.6*1.6*4M 6T) | 90 | 120 | 3~4 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS150*2 | 160 | 150 | 4~5 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS 150*2 (8*2*4.3M 8T ) | 200 | 150 | 6~7 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS185*2 | 315 | 185 | 8~10 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

| SPHS185*2 | 355 | 185 | 10~12 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

Richi Machinery

How does the Sinking Fish Feed Machine work?

Both fish feed pellet machine and fish feed extruder machine can produce sinking fish feed pellet, but the principles of sinking fish feed produced by the two feed production equipment are completely different.

The fish feed pellet machine mainly uses the strong squeezing effect of the roller and the ring die to compact the material into the membrane holes of the ring die to form sinking fish feed pellets.

The fish feed extruder machine is mainly used for the material to be squeezed, sheared and kneaded by the screw. When the material comes out of the membrane hole, its volume increases instantly to form extruded feed pellet. In addition to the starch content in the feed formula, the factors that affect the sinking and buoyancy of extruded feed pellets can also be controlled by controlling the temperature and humidity, as well as the screw profile and screw speed of the fish feed extruder machine.

In general, both sinking fish feed production processes can meet the production requirements of sinking fish feed pellet. Fish feed pellet machine can only be used to produce sinking feed pellets, while fish feed extruder machine can be used to produce both sinking fish feed pellets and floating fish feed pellets.

Application of Sinking Fish Feed Machine

— Richi Machinery —

Sinking fish feed pellets will sink quickly to the bottom of the water, which is very suitable for the feeding needs of bottom-dwelling fish as well as shrimps and crabs.

The fish sinking feed produced by our sinking fish feed machine or fish feed extruder machine can meet the feeding needs of bottom-dwelling fish such as catfish, salmon, sturgeon, bream, bass, etc.

For investors who have the demand for sinking fish feed production, our fish sinking feed pellet machine and fish feed extruder machine can meet the feed production needs of medium or large aquaculture farms and fish feed pellet mill.

Complete sinking fish feed production process

— Richi Machinery —

The fish sinking fish feed pellet machine orfish feed extruder machine is the core equipment in the process of producing fish sinking feed pellet. However, in order to industrially produce fish sinking feed pellet, medium or large aquaculture farms and feed pellet mill usually equip a complete aquatic feed production line according to their own production needs.

As professional sinking fish feed machine manufacturer, RICHI has designed turnkey feed production lines for thousands of customers. With rich experience in project design and project construction, it can provide customized fish sinking fish feed production line solutions for each customer.

The process flow of the standard fish feed production line is((Not every feed production project needs to be equipped with all of the following sections. All of our sections are modular in design and can be added or reduced according to your raw materials, capacity, plant size, degree of automation, etc.)

Receiving and processing of raw materials

Equipped with impurity removal equipment and storage system for raw materials.

The first crushing and the first mixing

Coarse crushing and uniform mixing of materials that account for a relatively large proportion in the feed formula.

Second crushing

Depending on the type of raw materials, you can choose to crush them again to meet the requirements of granulation or extrusion.

Pelleting (needed for pelleting process)

Using fish feed pellet machine with a double-layer modulator or a triple-layer modulator for pelleting.

Extrusion (required for extrusion process)

Use a single-screw fish feed extruder machine or twin-screw fish feed extruder machine to extrude the material into feed pellets.

Drying

Using belt dryer to dry the moisture content of the feed pellets to 10%-11% (more necessary for extrusion process).

Spraying

Post-spraying stage to further increase the oil content in feed pellets.

Cooling

Using pellet cooler to cool the feed pellets to room temperature to increase the hardness of the feed pellets.

Packing

An automatic packing system can be used to pack feed pellets into 10-50 kg bags.

Auxiliary Display

— Richi Machinery —

Complete fish feed pellet mill will be equipped with a set of complete sinking fish feed machine. In addition to the fish feed pellet machine or fish feed extruder machine, fish feed production may also use hammer mill, ultrafine grinders, mixers, coolers, drying machine, spraying equipment, packing equipment, etc.

Each sinking fish feed production line is designed according to the specific needs of the customer, so the equipment equipped for each sinking fish feed production project is different.

As sinking fish feed machine manufacturer, we can provide a full range of equipment with full production capacity required in the fish sinking feed production process.

Silo

Hammer Mill

Ultrafine Grinder

Dryer Machine

Spraying Equipment

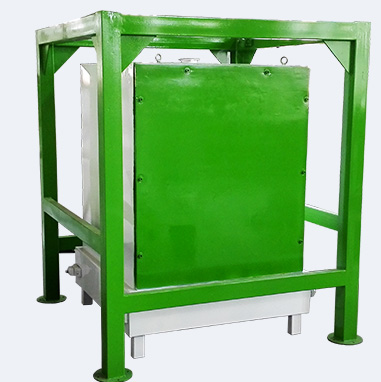

Square Plansifter

Rotary Screener

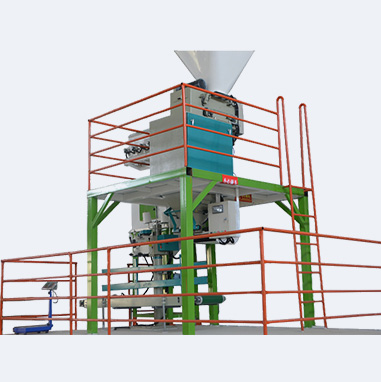

Packing Machine

Project of Fish Feed Production

— Richi Machinery —

RICHI feed pellet machine is widely welcomed in domestic and overseas markets. Currently, RICHI’s feed production projects and pellet production projects are spread over more than 120 countries and regions around the world, covering various production lines such as 1-60 tons per hour of livestock and poultry feed, high-end aquatic feed production line, etc.

With professional attitude and excellent quality, we deliver every feed production project to our customers!

1 t/h fish feed production line in the Philippines

Feed type: Sinking Aquatic Feed

Major equipment:

Hammer,Mill,Mixer,feed pellet machine,Cooler,Packing Machine

Features of fish feed production line:

TThis is a small-capacity fish feed production line purchased by a customer from the Philippines. The entire feed production line is designed to be compact, and all feed pellet machine is laid out as flat as possible. The highest point is less than 11 meters, and the overall investment is not large. The customer hopes to enter the aquatic feed production industry through this small-capacity fish feed production line.

5 t/h sinking fish feed pellet mill in Uzbekistan

Feed type: Sinking fish feed

Major equipment:

Silo,Hammer mill SFSP 66*60,Ultrafine grinding equipment SWFL 130E,Feed Mixer 500KG/P,feed pellet machine,Dryer Machine SKG12000-5ZP,Spraying Equipment,Feed Cooler,Packing machine,Steam boiler

Features of sinking fish feed pellet mill:

This is a fully automatic sinking fish feed production line, equipped with a fully automatic raw material receiving and processing system, a fully automatic batching system, and a fully automatic packing system. The production efficiency of the entire sinking fish feed pellet mill is relatively high.

2.5-5 t/h shrimp feed & 8-12 t/h sinking fish feed production line in India

Feed type: Sinking fish feed, shrimp feed

Major equipment:

Mixing machine SLHY.0.5A,Hammer mill SFSP56*40,Pellet machine SZLH420,AutHammer mill SFSP 66*100,Silo,Feed Mixer 1000KG/P,Ultrafine grinding equipment SWFL 110C,Square Plansifter,feed pellet machine,Feed Cooler,Packing machine,Steam boiler

Features of sinking fish feed pellet mill:

The production line is equipped with a feed pelletizer with a three-layer modulator, which can meet the production needs of both fish feed and shrimp feed. The outer layer of the modulator of the feed pelletizer is equipped with a jacket device, which enables the material to be better modulated and meet the requirements of shrimp feed pelletizing.

According to the raw materials used by customers, hammer mill is used for both crushing operations, which can reduce costs while ensuring that the crushing fineness of the materials meets the pelleting requirements.

3-5 t/h sinking fish feed and livestock feed production line in Thailand

Feed type: Fish feed, chicken, pig and other livestock feed

Major equipment:

Hammer mill SFSP 66*60,Feed Mixer 500KG/P,feed pellet machine,Feed Cooler,Packing machine,Steam boiler

Features of feed production line:

This is a conventional compound feed production line. Due to the need to produce fish sinking feed, it is equipped with a feed pellet machine with a double-layer modulator. The feed pellet machine can be used to produce fish sinking feed and livestock and poultry feed at the same time, which can maximize the use of the feed factory’s production equipment and improve the production efficiency of the feed pellet mill.

Sinking fish feed machine can be customized design

Each customer has different raw materials, production requirements and local production conditions, and the equipment required is also different. RICHI can customize fish feed pellet machines or fish feed extruder machine for you according to the specific needs of each customer.

The starting point of all designs is to focus on customer needs and customize high-quality sinking fish feed machine for each customer.

Frequently asked questions

I need Sinking Fish Feed Machine,What is the price of fish feed extruder?

The price of our fish sinking fish feed machine is between 7000-100000 USD. The reason why we did not give you a definite price directly is that the price of sinking fish feed machine with different output and different configuration is different. So first we need to communicate with you and understand your specific needs before we can recommend you the appropriate sinking fish feed production machine and tell you the exact price of fish sinking feed production machine.

I wI need to build a small fish feed plant, what equipment do I need?

The main equipment of the sinking fish feed pellet mill is the production equipment needed for the sinking fish feed production line. The conventional sinking fish feed production line needs to use: feed crusher, feed mixer, feed pelletizer, feed dryer, feed cooler, packing equipment, etc.

In addition to these equipment, some auxiliary equipment is also needed, such as screening equipment, conveying equipment, etc. What equipment is needed on the entire fish feed production line still needs to be equipped according to your needs.

In addition to feed production machine, fish feed pellet mill building needs to be built. After the fish feed production plan is determined, the factory building can be built according to the production plan.

Can the pellet mills used to produce poultry feed also be used to produce fish feed?

No. Both single-layer and double-layer feed pellet machines can be used to produce poultry feed. However, if you need to produce fish sinking feed, considering the requirements of sinking fish feed on the degree of maturity and the feeding characteristics of fish, a feed pellet machine with a double-layer feed pellet machine is generally required.

Therefore, not all pellet machines used to produce poultry feed can be used to produce sinking fish feed.

Do you have an office in Vietnam? I would like to communicate directly with local staff.

We do not have an office in Vietnam. Once customers contact us, we will ask the sales manager responsible for the area to contact you and communicate the detailed information about the feed production machine you need.

You can also come to our factory directly. Our sales manager and technical engineer can take you on a field tour and explain our feed production equipment to you. In this way, the communication efficiency between us will be faster.

We welcome every customer to visit our factory for communication at any time.