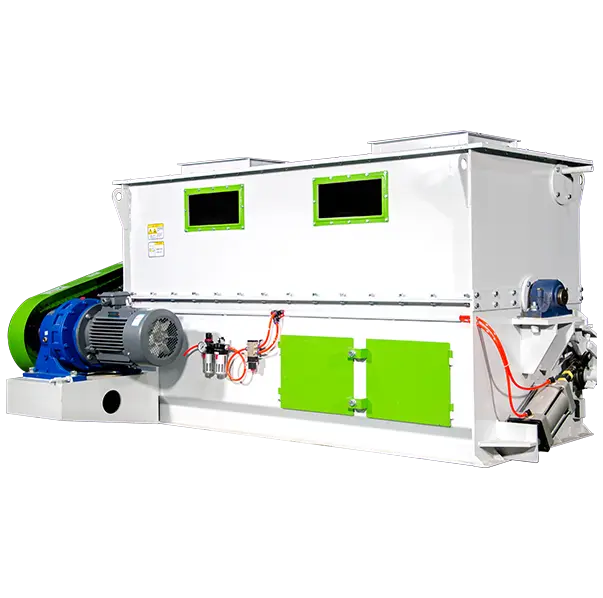

Single Shaft Ribbon Mixer

SLHY series single-shaft ribbon mixer has large effective volume and high mixing efficiency, and is suitable for mixing a variety of raw materials and liquids.

Capacity: 500-2000 kg/P

Guiding price: 5000-40000 USD

A very important section in the feed production process is the mixing section, which is where the various crushed raw materials are discharged from the mixing bin into the mixer, and premixes, liquids, oils, etc. are added as needed to mix the components evenly to achieve the desired mixing effect. The main equipment used in this process is the mixer.

RICHI SLHY series single shaft double ribbon mixers are widely used in small and medium-sized feed mills to mix powdered materials. They have a large effective volume and can also add various liquids (such as water, syrup, oil, etc.) to make the components of the mixture evenly distributed and ensure the quality of the compound feed.

+86 150 9316 3243

RICHI MACHINERY

How Does The Single Shaft Ribbon Mixer Work?

In the convection process of the single shaft paddle mixer, multiple materials are mixed with each other through pThe barrel of RICHI single shaft ribbon mixer is a horizontal structure, and the internal rotor is composed of ribbon spiral blades, shafts, rings, and support rods. The blades are divided into two circles, inner and outer. When the rotor rotates, the left-handed blades push the material from one end to the other, and the right-handed blades move the material in the opposite direction. Through such continuous turning and convection, the materials are evenly mixed.

Scraper plates are welded on the outer blade support rods at both ends of the rotor, close to the inner wall of the machine, so that the materials in the four corners of the machine can be fully stirred.

RICHI MACHINERY

Advantages of Single Shaft Paddle Mixer

- The spiral ribbon is specially designed with narrow outer spiral ribbon and wide inner spiral ribbon, so as to achieve a good mixing effect;

- Two discharging methods are designed: side discharging and bottom large door discharging, which can be selected according to needs;

- The mixing time for each batch is 3 to 6 minutes, which is especially suitable for mixing materials with more liquid added;

- The mixer is equipped with a grease adding pipeline, the overall structure is reasonable, and the operation and maintenance are convenient;

- Using uniquely designed rotor structure, the coefficient of variation of mixing uniformity CV≤7%;

- The shaft end and discharge door adopt unique and mature sealing technology to ensure no leakage.

RICHI MACHINERY

Single Shaft Ribbon Mixer Parameters

The models and capacity of common single shaft ribbon mixer we produce are as follows:

RICHI MACHINERY

Different Types of Single Shaft Ribbon Mixer

SLHY0.5A Single Shaft Ribbon Mixer

Power:

4 kw

Mixing amount:

250 kg/P

SLHY1.0A Single Shaft Ribbon Mixer

Power:

7.5 kw

Mixing amount:

500 kg/P

SLHY2.5L Single Shaft Ribbon Mixer

Power:

18.5 kw

Mixing amount:

1000 kg/P

SLHY5.0L Single Shaft Ribbon Mixer

Power:

30 kw

Mixing amount:

2000 kg/P

RICHI MACHINERY

Single Shaft Ribbon Mixer Can Be Customized

The above are only some of the mixer models we produce. As an important process in feed production, mixer is an indispensable equipment. We can customize single shaft ribbon mixer for you according to your production needs.

If you have special requirements for the mixer, such as the mixing volume of each batch of the mixer, the mixing requirements of special raw materials, the discharging method of the mixer, the mixer requirements for special materials, etc., you can contact us directly and professional engineers will provide you with a suitable customized solution.

RICHI MACHINERY

Precautions During The Use of The Single Shaft Ribbon Mixer

If you want to improve the mixing effect of materials, choosing high-quality mixer is a prerequisite. During the use of the mixer, operation is also very critical. Correct operation can achieve better mixing effects.

Therefore, during the operation of the mixer, the following matters should be noted:

01 Filling coefficient

Appropriate loading conditions can not only make the mixer work normally, but also achieve the expected mixing effect. For single shaft ribbon mixer, filling coefficient of 0.6 to 0.8 is more suitable, and the material level should not exceed the top plane of the rotor;

02 Order of operations

The mixing process of the mixer is generally divided into three parts. The first is the mixing of large materials, that is, the raw materials that account for a relatively large proportion of the feed formula are crushed and then put into the mixer for mixing; the second is the mixing of small materials, that is, the premix and the mixed large materials are mixed again; the last is the wet mixing, that is, the addition of oil and liquid; the mixing order directly affects the final mixing effect;

03 Mixing time

The mixing time is determined according to the characteristics of the mixed materials. The mixing time of each batch of RICHI ribbon mixer is 3 to 6 minutes. If the mixing time is too short, the materials cannot be fully mixed; if the mixing time is too long, it will increase energy consumption and reduce production. In addition, excessive mixing will cause the separation and accumulation of material components, thereby reducing the mixing uniformity;

04 Periodic inspection

After the mixer has been used for a long time, the sealing strip of the door will age and wear out. The operator should regularly check whether there is leakage in the mixer door. If there is leakage, it should be repaired in time and the relevant vulnerable parts should be replaced.

RICHI MACHINERY

Production Process of Single Shaft Ribbon Mixer

RICHI single shaft ribbon mixer is fully responsible for design, production, delivery and installation by our professional staff.

When the mixer is produced in our workshop, we will send the corresponding pictures and videos to customers so that they can understand the production process of the mixer at any time.

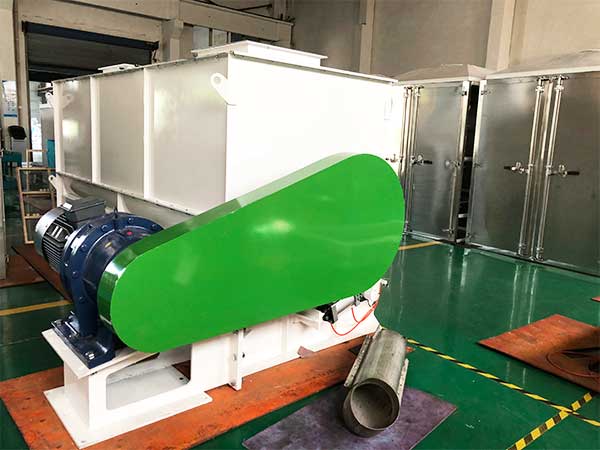

Mixer semi-finished products

Mixer finished products in the workshop

Delivery of mixer

Mixer installation

Can’t Find The Single Shaft Ribbon Mixer You Want?

Contact Us To Customize For You!

RICHI MACHINERY

Application of Single Shaft Ribbon Mixer

RICHI single shaft ribbon mixer is not only suitable for mixing in the feed production process, but also for the material mixing needs of many other industries, such as powder, granular, flaky, and miscellaneous materials in the food, chemical, pharmaceutical, pesticide and other industries.

Single Shaft Paddle Mixer in Animal Feed Mill

The single shaft ribbon mixer has a large volume and is particularly suitable for mixing raw materials with a lighter bulk density, such as grass powder.

Single Shaft Paddle Mixer in Fish Feed Pellet Mill

We provide individual single shaft ribbon mixer for fish feed as well as complete fish feed production machine and fish feed turnkey projects.

Single Shaft Paddle Mixer in Chemical Industry

Single shaft ribbon mixers are available for use in a variety of industries.

RICHI MACHINERY

You May Also Like

Mixing is an important process in the feed production process. As a professional feed pellet machine manufacturer, we can not only provide customers with mixers, but also provide other equipment required in the feed production process, such as hammer mill, ultrafine grinders, feed pellet machine, feed extruder, coolers, drying machine, packing equipment, etc.

RICHI can provide full set of poultry feed production equipment, livestock feed production equipment, animal feed production equipment, aquatic feed production equipment and feed production turnkey projects to meet the production needs of each customer.