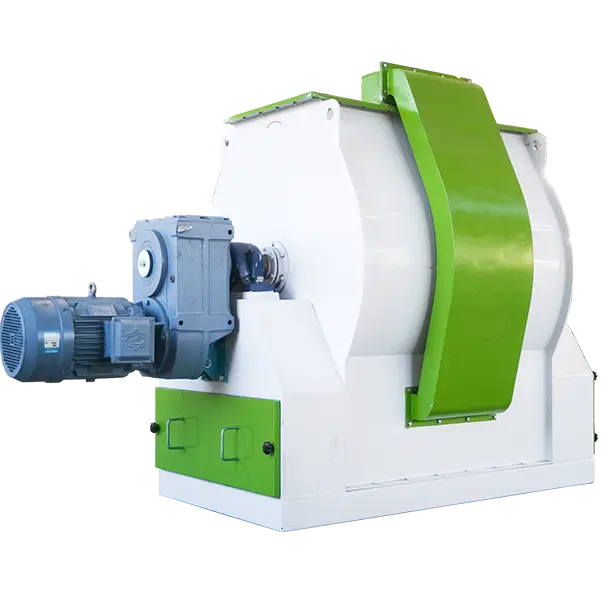

Single Shaft Paddle Mixer

RICHI provides high-quality single-shaft paddle mixers, which can be used in feed, chemical, organic fertilizer and other industries.

Capacity: 500-3000 kg/P

Guiding price: 5000-40000 USD

Mixing is the process of mixing various feed raw materials with each other under the action of external force to make them evenly distributed after they have been metered. In the feed production process, in order to fully mix the materials and obtain high-quality finished feed pellets, the materials need to be mixed after they are crushed and before they are extruded and pelletized.

RICHI SLHJ series Single Shaft Paddle Mixer, also called Single Shaft Double Layer Paddle Mixer, is suitable for mixing feed, chemicals, organic fertilizer and viscous materials. The equipment is equipped with housing, cover, paddle shaft, discharge mechanism, motor reducer, transmission mechanism, and air outlet.

+86 150 9316 3243

RICHI MACHINERY

How Does The Single Shaft Paddle Mixer Work?

In the convection process of the single shaft paddle mixer, multiple materials are mixed with each other through penetration and displacement, and then mixed during the tumbling process on both sides. This is repeated many times and finally mixed by the discharge device. Then the materials are discharged from the discharge door.

Our feed mixer is made of stainless steel and can add a variety of liquids into the mixture, such as water, molasses, oil, etc.

RICHI MACHINERY

Advantages of Single Shaft Paddle Mixer

The mixing uniformity is as high as 98% and the mixing time is short.

Fully open discharge door, smaller gap between blade and casing, zero leakage.

The extra-large inspection door is convenient for cleaning and maintenance, saving time; and it is equipped with a travel switch to protect personal safety.

Adopting gear transmission, the later maintenance cost is low, only need to add lubricating oil regularly.

The discharge port adopts a pneumatic gate to speed up the discharge process, shorten the mixing period and improve the overall production efficiency.

Plough blade structure. The paddle feed mixer adopts a plowshare design, with low material residue, high working efficiency and large mixing capacity.

RICHI MACHINERY

Single Shaft Paddle Mixer Parameters

The models and capacity of common single-shaft paddle mixers we produce are as follows:

| Model | Motor connection | Material | Power (kw) | Mixing amount per batch (kg/P) | Effective volume (m³) |

| SLHJ1A | Direct connection | Carbon steel | 11 | 500 | 1 |

| SLHJ1B | Direct connection | Stainless steel | 11 | 500 | 1 |

| SLHJ2A | Direct connection | Carbon steel | 22 | 1000 | 2 |

| SLHJ2B | Direct connection | Stainless steel | 22 | 1000 | 2 |

| SLHJ2L | Chain | Carbon steel | 22 | 1000 | 2 |

| SLHJ3A | Direct connection | Carbon steel | 30 | 1500 | 3 |

| SLHJ4L | Chain | Carbon steel | 30 | 2000 | 4 |

| SLHJ4A | Direct connection | Carbon steel | 37 | 2000 | 4 |

| SLHJ6A | Direct connection | Carbon steel | 55 | 3000 | 6 |

RICHI MACHINERY

Different Types of Single Shaft Paddle Mixers

SLHJ1A Single Shaft Paddle Mixer (Carbon Steel)

Power:

11 kw

Mixing amount:

500 kg/P

SLHJ1B Single Shaft Paddle Mixer (Stainless Steel)

Power:

11 kw

Mixing amount:

500 kg/P

SLHJ2A Single Shaft Paddle Mixer

Power:

22 kw

Mixing amount:

1000 kg/P

SLHJ4A Single Shaft Paddle Mixer

Power:

37 kw

Mixing amount:

2000 kg/P

RICHI MACHINERY

single Shaft Paddle Mixer Can Be Customized

The above are just some of the single shaft paddle mixers we produce for our customers. As the main equipment needed in the pre-treatment stage of feed pellet production such as poultry feed, livestock feed, aquatic feed, etc., we can customize single shaft paddle mixers for customers according to their needs.

If you have special requirements for mixing, such as special raw material mixing requirements, special capacity requirements, special material requirements for the mixer, etc., we can customize it according to your needs.

RICHI MACHINERY

Technical Standards for Single Shaft Paddle Mixers

Technical Standards for Single Shaft Paddle Mixers

In the production process of single shaft paddle mixer, the main technical indicators used to measure the quality of the mixer are: mixing volume per batch, mixing uniformity, mixing speed and residual material rate in the machine.

01 The requirements for mixing uniformity are relatively high.

The feed standard stipulates that the mixing uniformity coefficient of compound feed is ≤10%, and the mixing uniformity coefficient of premixed feed is ≤5%. However, the mixing uniformity of the single shaft paddle mixer we produce can reach more than 98%, which can fully meet the requirements of the feed standard;

02 Mixing time should be short.

The mixing time of the mixer determines the mixing cycle, so the length of the mixing time directly affects the productivity of the feed pellet production line;

03 The residual rate in the mixer should be as low as possible.

To avoid cross contamination and ensure the quality of each batch of products, the residual rate in the compound feed mixer is ≤1%, and the residual rate in the premixed feed mixer is ≤0.8%. The residual rate in our mixer is much lower than the specified data;

04 The mixer is reasonably designed.

The mixer must meet the mechanical performance requirements such as reasonable and simple structure, no leakage, easy inspection, sampling and cleaning.

RICHI MACHINERY

Production Process of Single Shaft Paddle Mixer

RICHI single shaft paddle mixer is fully responsible for design, production, delivery and installation by our professional staff.

When the mixer is produced in our workshop, we will send the corresponding pictures and videos to customers so that they can understand the production process of the mixer at any time.

Mixer semi-finished products

Mixer finished products in the workshop

Delivery of mixer

Mixer installation

Can’t Find The Single Shaft Paddle Mixer You Want?

Contact Us To Customize For You!

RICHI MACHINERY

Application of Single Shaft Paddle Mixer

The single shaft paddle mixer developed by RICHI can meet the mixing needs of various raw materials. It is widely used in the production of feed, wood pellets, organic fertilizer, chemical industry and other industries. It can achieve better mixing effect and is favored by many customers.

Single Shaft Paddle Mixer in Feed Mill

Single shaft paddle mixer is widely used for mixing raw materials in poultry feed mill, fish feed pellet mill, shrimp feed mill etc.

Single Shaft Paddle Mixer in Wood Pellets Plant

We offer single-shaft paddle mixers for mixing a variety of wood pellet raw materials.

Single Shaft Paddle Mixer in Organic Fertilizer Factory

Provide organic fertilizer granule raw material mixer and organic fertilizer granule production equipment, as well as organic fertilizer granule production line turnkey project.

RICHI MACHINERY

You May Also Like

The mixing section is a relatively important section in the entire feed production process. In addition to the mixing section, the complete feed production process also includes a crushing section, pelleting or extrusion section, cooling section, screening section, packing section, etc.

Therefore, in addition to mixers, the entire feed production process also requires hammer mill, ultrafine grinders, feed pellet machine, feed extruder, coolers, drying machine, packing equipment, etc.

As professional feed production equipment manufacturer, RICHI can provide full set of feed pellet production to meet the production needs of every customer.