Customized Turnkey shrimp Feed Production Project

Shrimp Feed pellet line

0.5-40 t/hour shrimp feed pellet line solutions.

We can provide a full set of shrimp feed production machine and turnkey projects shrimp feed production line.

Introduction of Shrimp Feed pellet line

— Richi Machinery —

Introduction

As global leading shrimp feed making machine manufacturer, we have been deeply involved in the field of shrimp feed pellet production for nearly 30 years. We can provide you with a full set of shrimp feed making machine, shrimp feed pellet line turnkey projects, and customized solutions for shrimp feed pellet mill.

Our experience and expertise enables us to provide you with comprehensive advice and hassle-free service throughout your shrimp feed production process.

Application : It can produce shrimp feeds such as Litopenaeus vannamei, Penaeus monodon, Litopenaeus setiferus, Farfantepenaeus aztecus, red tail shrimp, Macrobrachium rosenbergii, etc.

Raw materials: Fish meal, soybean meal, soybean cake, peanut cake, wheat bran, bran, flour, shrimp head powder, yeast powder, soybean lecithin, clam shell powder, etc.

0.5-40

Capacity(ton/hour)

0.6-4

Feed pellet size(mm)

Advantages of floating fish feed mill

Customized Design

The shrimp feed pellet mill can be customized according to the size of the plant and specific needs.

Modular Design

The entire process of the shrimp feed pellet line is modular in design, and the production sections can be increased or decreased according to the raw materials used and special needs.

Automation

Fully automated, semi-automated, and manual production processes can be selected according to demand.

Pelleting process and extrusion process

Based on the raw materials, local demand, quality of finished feed pellets, etc., you can choose the pelletizing process or the extrusion process.

One line for multiple uses

It can be used not only to produce shrimp feed pellets, but also to produce various fish feed pellets as well as poultry and livestock feed pellets.

Turnkey Projects

We provide full-process services from the design of shrimp feed pellet line to the production and installation of equipment.

Capacity of shrimp feed pellet line

RICHI can build shrimp feed pellet line and shrimp feed pellet mill with different capacitys to meet the production needs of customers in different regions.

The most common solution is the turnkey project solution of 0.5-40 tons shrimp feed pellet line, but if you have any special needs in terms of capacity, please contact us directly!

1 t/h shrimp feed pellet mill

Small shrimp feed pellet mill can meet the investment of large shrimp farming or small and medium shrimp feed pellet mill.

5 t/h shrimp feed pellet plant

According to the development of local fish and shrimp farming industry and the market demand for fish and shrimp feed pellet, it can meet the investment needs of investors with medium or large shrimp feed pellet mill.

0.5 t/h

1-2 t/h

3-5 t/h

10 t/h

10-18 t/h

Finished shrimp feed pellet

— Richi Machinery —

The shrimp feed pellet line we design and the shrimp feed pellet mill we build can produce pellet shrimp feed and extruded shrimp feed to meet the breeding needs of various shrimps and crabs such as whiteleg shrimp, Pacific white shrimp, black tiger shrimp, giant tiger shrimp, white shrimp, brown shrimp, red tail shrimp, Macrobrachium rosenbergii, etc.

Litopenaeus vannamei

Penaeus monodon

Litopenaeus setiferus

Farfantepenaeus aztecus

Red tail shrimp

Macrobrachium rosenbergii

shrimp feed production process

— Richi Machinery —

RICHI has always been at the forefront of feed pelletizing and extrusion technology, and attaches great importance to the innovation of shrimp feed pellet production technology.

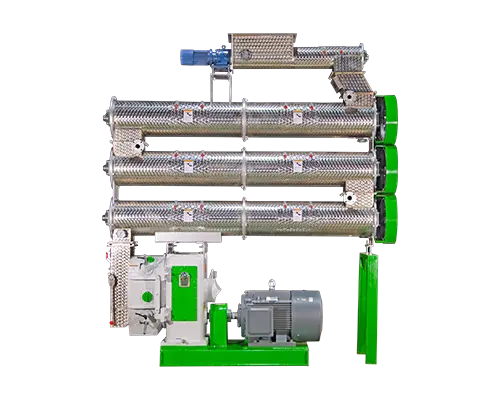

There are two main processes for producing shrimp feed pellet: using shrimp feed making machine to produce shrimp feed pellets and using an shrimp feed extruder to produce extruded shrimp feed.

Among them, the method of using pelleting process to produce shrimp feed pellet is a more common shrimp feed production process, but with the demand for shrimp feed farming and the continuous improvement of shrimp feed pellet technology, many places have begun to use extruders to produce shrimp feed.

As well-known feed making machine manufacturer, no matter which process customers choose to use to produce shrimp feed, RICHI can provide the best solution and a full set of shrimp feed making machine.

Shrimp feed pelleting process: Raw material receiving and cleaning – coarse crushing – first mixing – second crushing – second mixing – pelletizer – post – ripening – spraying – screening – packaging

Shrimp feed extrusion process: Raw material receiving and cleaning – coarse crushing – first mixing – second crushing – second mixing – extrusion – post – ripening – spraying – screening – packaging

shrimp feed pellet line

This is the standard shrimp feed production process. Each section is modular in design. Not every customer’s shrimp feed pellet lineneeds to use all of the above sections. Sections can be added or reduced according to specific needs; and the equipment equipped in each section will also be adjusted according to raw materials, capacity and other requirements.

RICHI’s Footprints

— Richi Machinery —

RICHI has footprints in more than 120 countries and regions around the world, serving global customers with high-end quality; with more than 200 classic cases, it has become a leader in the field of feed making machine.

1.5-2 t/h fish and shrimp feed pellet line in Iran

Feed types: Shrimp feed, floating fish feed and sinking feed

Features of fish and shrimp feed pellet line:

The shrimp feed production project is located in Iran. The feed pellet millis equipped with both pellet mills and extruders, so it can be used to produce extruded fish and shrimp feed as well as poultry and livestock feed pellets.

Since the customer’s feed production project site had height requirements, we eventually changed the feed pellet line from more than 20 meters high to 8 meters high.

3-4 t/h shrimp feed pellet mill in Algeria

Feed types: Shrimp Feed Pellets

Features of fish and shrimp feed pellet mill:

The modulator of the pelletizer on this shrimp feed pellet line is high configuration, using a dual-axis differential modulator + a quality control device + a jacketed modulator, and the raw materials have a relatively high degree of maturation.

After pelleting, a post-maturation device is installed to further increase the maturity of the feed and improve the quality of feed pellets.

2 t/h shrimp feed pellet line in Indonesia

Feed types: Shrimp Feed Pellets

Features of fish and shrimp feed pellet line:

The entire shrimp feed pellet line has a high degree of automation, including a fully automatic batching system and a fully automatic packing system.

Equipped with a special shrimp feed pellet crumbler, the shrimp feed pellet can be crushed to 0.6mm to meet the needs of some shrimp and crab farming factories.

5 t/hour shrimp feed and poultry feed pellet line in India

Feed types: Shrimp feed, chicken, duck, goose and other poultry feed

Features of shrimp feed and poultry feed pellet line:

The feed pellet prodiction project is equipped with an extruder and a pelletizer. The extruder is mainly used to produce shrimp feed, and the pelletizer is mainly used to produce poultry feed.

Using an extruder to produce high-end shrimp feed with a higher degree of maturity, which can improve shrimp survival rate and weight gain rate.

Customized shrimp feed pellet line design

— Richi Machinery —

Customized solutions can help different customers achieve their unique business needs, improve efficiency and reduce costs.

RICHI All of shrimp feed pellet lines are customized. We design professional shrimp feed pellet mill for customers based on different raw materials, site size and height restrictions, automation requirements, and production needs.

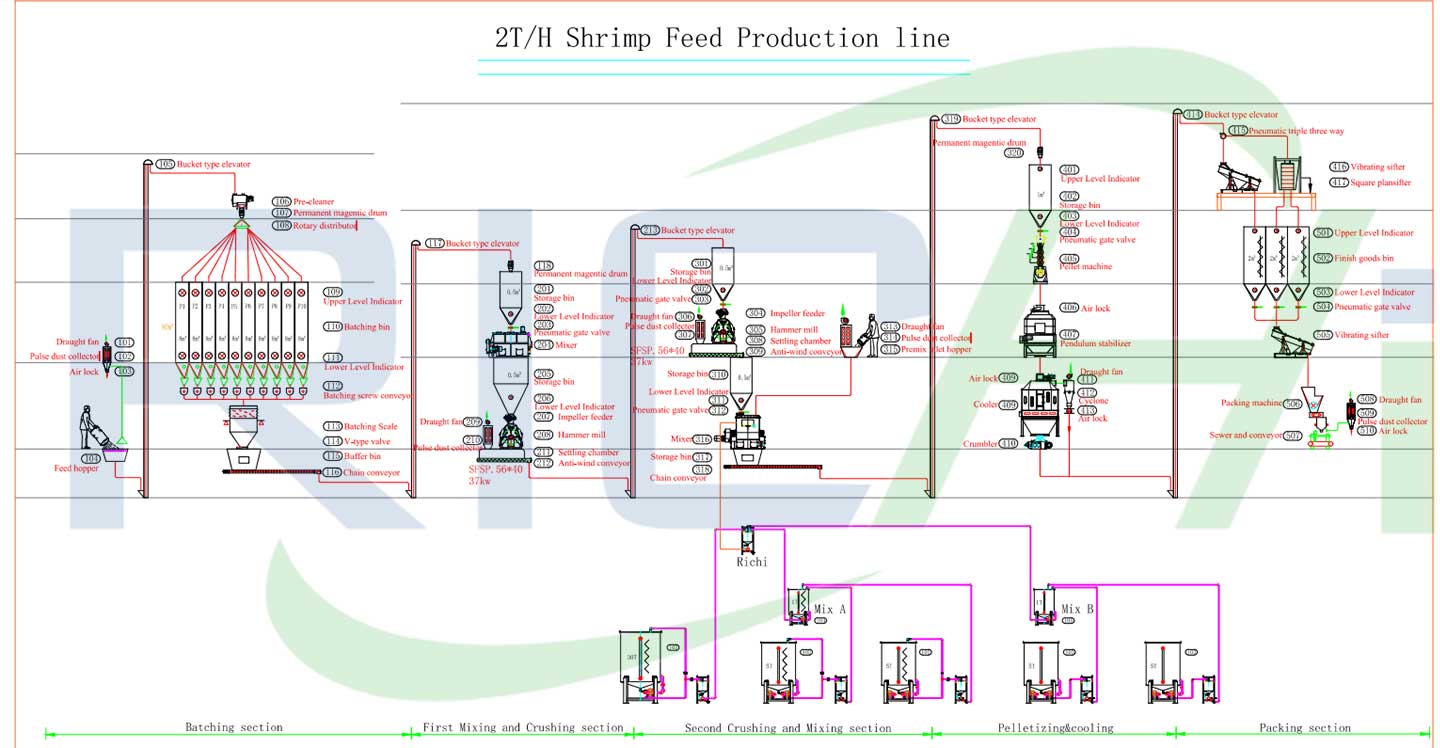

2T/H Shrimp Feed Production line

Type of Feed Produced: Shrimp feed pellet

Process flow: batching system – first mixing and first crushing system – second mixing and second crushing system – pelleting and cooling system – packaging system

Main equipment used: batching scale, hammer mill, feed mixer, ultrafine pulverizer, feed pelletizer, cooler, screening equipment, packaging machine

2.5-5T/H Shrimp Feed Pellet Making Line

Type of Feed Produced: Shrimp feed pellet

Process flow: Raw material receiving system – crushing system – batching and mixing system – ultrafine crushing system – second mixing system – pelleting and cooling system – packaging system

Main equipment used: crusher, mixer, ultrafine crusher, shrimp feed making machine, post-ripening machine, cooler, packaging machine

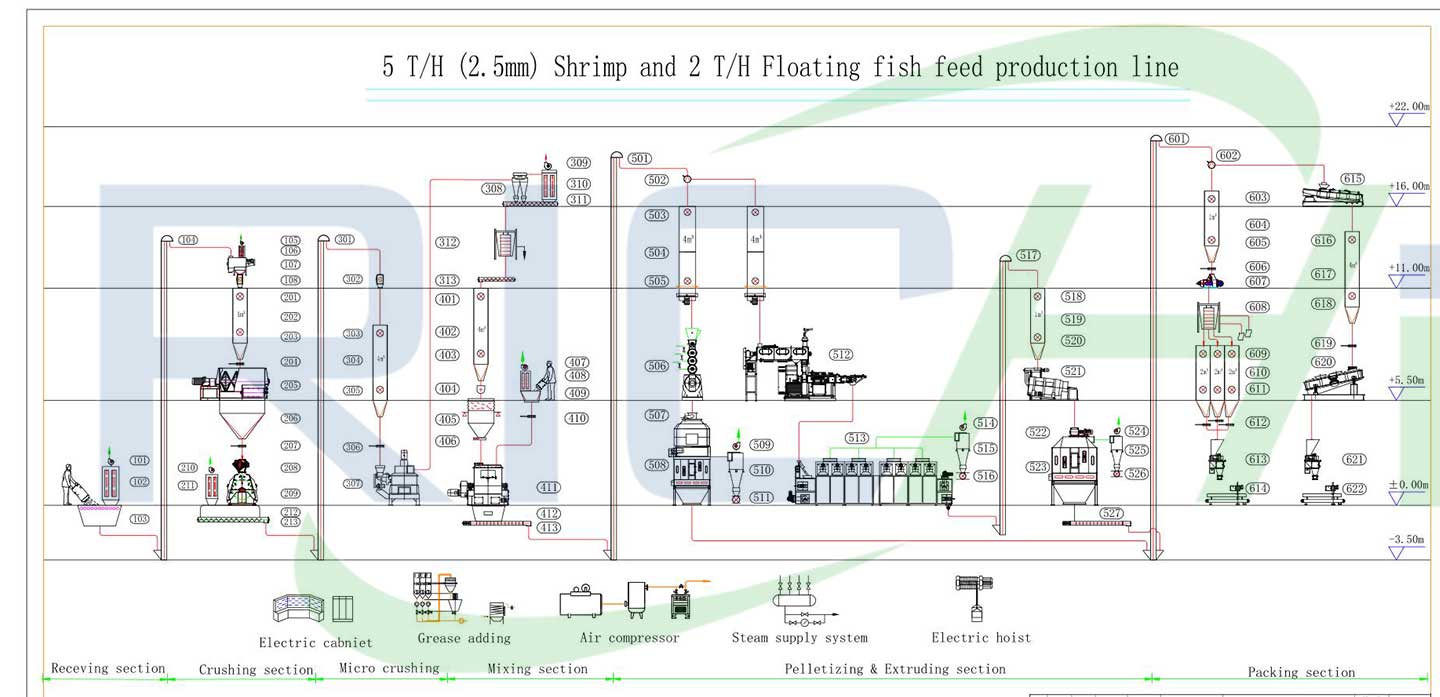

5 T/H(2,5mm)Shrimp and 2 T/H Floating fish feed production line

Type of Feed Produced: Shrimp feed pellet, Floating fish feed

Pelleting process: Raw material receiving-crushing system-mixing system-pelleting system-cooling system-packaging system

Extrusion process:Raw material receiving-crushing system-mixing system-extrusion system-drying system-cooling system-packaging system

Main equipment used: hammer mill, ultrafine grinder, mixer, shrimp feed making machine, extruder, drying equipment, cooler, packing machine

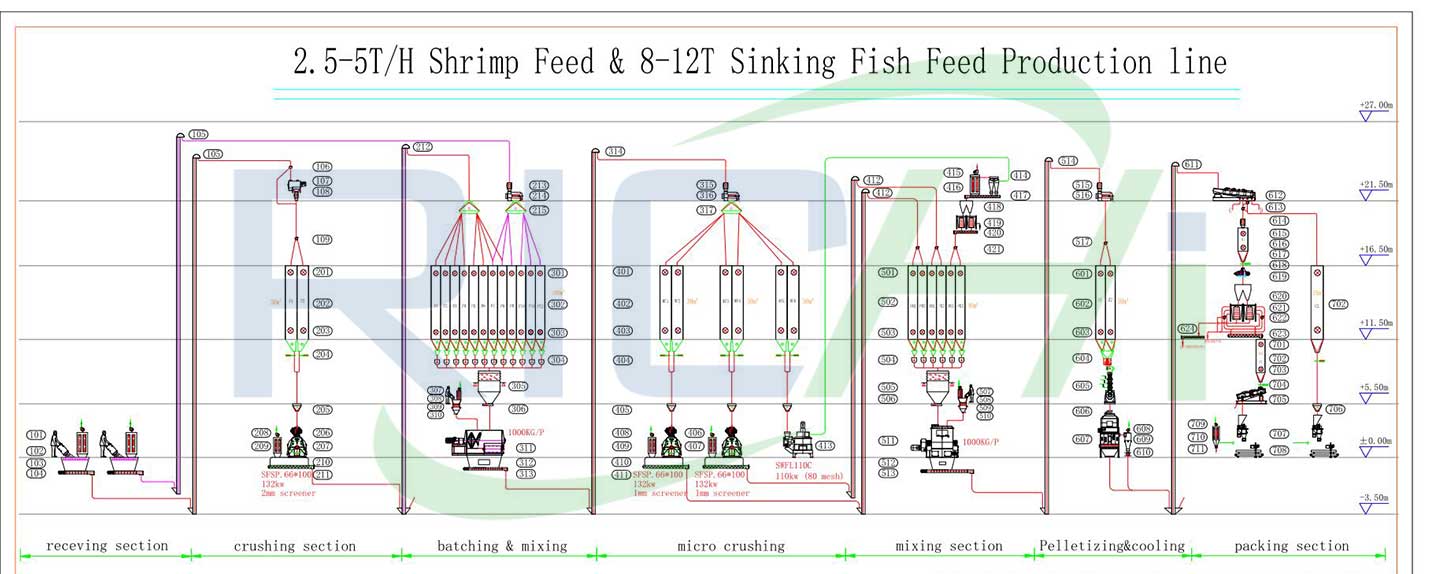

2.5-5T/H Shrimp Feed & 8-12T Sinking Fish Feed Production line

Type of Feed Produced: Shrimp feed pellet, sinking fish feed

Process flow: Raw material receiving-crushing system-batching and mixing system-micro crushing system-mixing system-pelleting and cooling system-packing system

Main equipment used: hammer mill, batching scale, mixer, ultrafine grinder, shrimp feed making machine, cooler, packing machine

Frequently Asked Questions

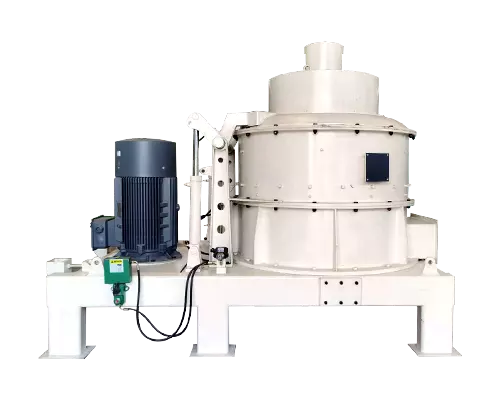

What is the difference between a shrimp feed pellet machine and a regular animal feed pellet machine?

First, in order to meet the requirements of maturation, the shrimp feed pelletizer needs to be equipped with at least three layers of modulators, and the three layers of modulators can be jacketed according to needs (to keep warm and prevent heat loss); or one or two layers of modulators can be replaced with differential modulators (to extend the maturation time); or one layer of modulators can be replaced with a quality preserver (which has a larger diameter and can extend the maturation time);

Secondly, shrimp feed pelletizing machines generally use 6P motors, while ordinary feed pelletizing machines generally use 4P motors, because shrimp feed pellet is the most difficult to pelletize among all feeds;

In addition, the cutter of the shrimp feed pelletizer is a very thin blade, which is close to the inner side of the ring die and can directly cut off the pellets, while the cutter of the ordinary pelletizer is a blade head, and the pellets hit the blade head and are broken.

Is it necessary to use feed extruder to produce shrimp feed pellet?

Of course it is necessary. In Asia, more than 90% of shrimp feed production still uses traditional compression pelleting technology. However, in the past decade, as extruded shrimp feed and extruded fish feed produced by European manufacturers entered the international market, people began to become interested in the development and use of shrimp feed extrusion technology. Some Asian manufacturers have begun to try to use feed extruders to produce extruded shrimp feed, and the response has been good.

Therefore, shrimp feed manufacturers or investors in the feed field can choose to use pelleting technology or extrusion technology to produce shrimp feed according to local market demand and their own financial budget.

What are the advantages of extruded feed produced by shrimp feed extruder?

• The degree of starch gelatinization is relatively high, reaching 95%-100%

• Produces 100% sinking feed with a wide variety of raw materials

• Feeding extruded feed improves shrimp survival and weight gain

• Extruded feed can effectively eliminate Salmonella, E. coli, Listeria, etc. during the processing process, reducing the disease rate of shrimp

• Can sink quickly and has high water stability

Can the shrimp feed production line only produce a single type of shrimp feed pellet?

No. The shrimp feed production line can be used exclusively to produce shrimp feed, but from the above customization plan, we can see that if there are production needs for fish feed, poultry feed pellet, livestock feed pellet, etc. When designing your feed production solution, we take all your feed production needs into consideration and customize a compound feed production line that can produce a variety of feed types.

Such as 1 t/h fish and shrimp feed production line, 5 t/h poultry and shrimp feed pellet line, 3-4 t/h shrimp and poultry, livestock feed pellet line and so on.