Shrimp Feed Making Machine

High Quality Shrimp Feed Making Machine

Customized Shrimp Feed Production Solutions

Shrimp Feed Making Machine

Shrimp Feed Pellet Machine

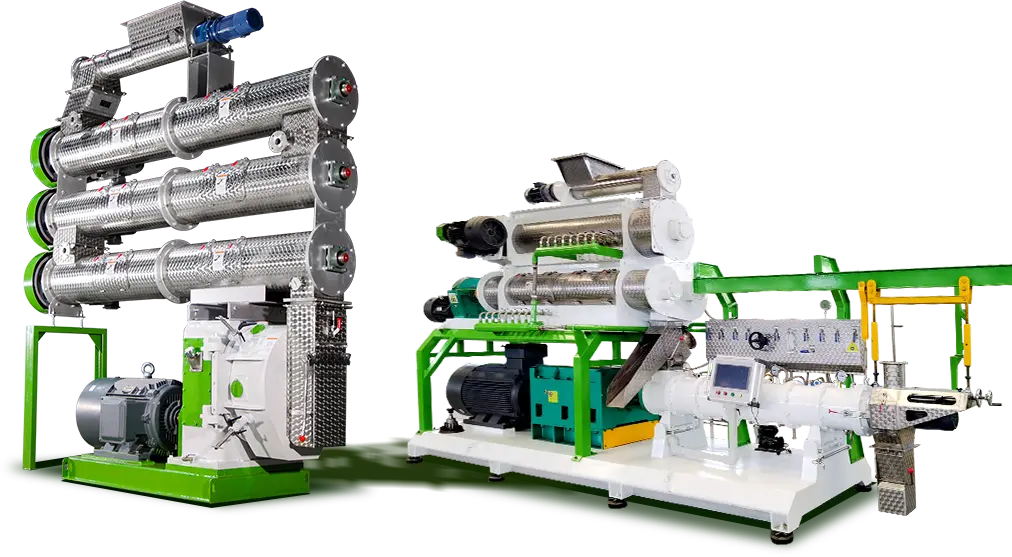

RICHI shrimp feed making machine can be used to produce feed that meets various shrimp needs. There are currently two main types of equipment used to produce shrimp feed pellet: one is shrimp feed pellet machine with three-layer modulator, which uses pelleting process to produce shrimp feed pellet.

Shrimp Feed extruder

The other is the shrimp feed extruder, including single-screw feed extruder and twin-screw feed extruder, which mainly adopts extrusion process to produce shrimp feed pellets.

As professional feed pellet making machine manufacturer, RICHI can provide you with reliable shrimp feed making machine and shrimp feed pellet production projects to meet your shrimp feed production needs.

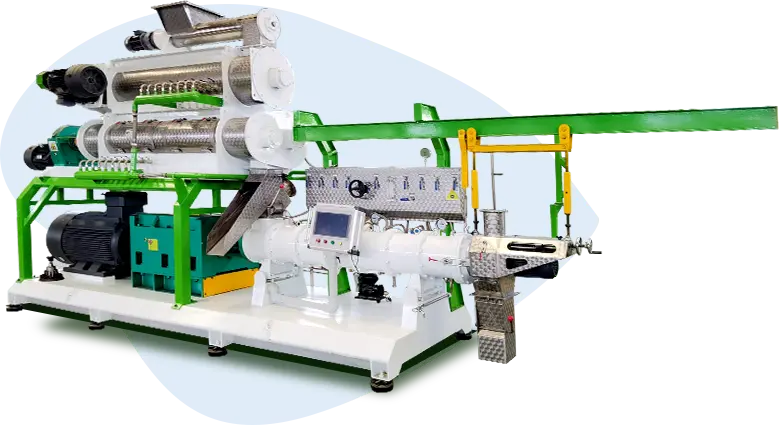

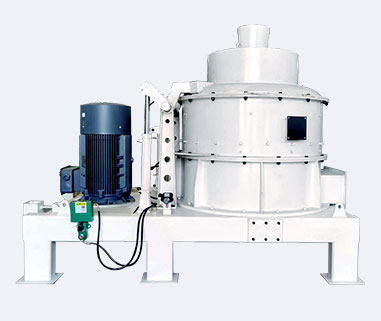

Shrimp Feed Pellet Machine

— Richi Machinery —

RICHI shrimp feed pellet machine is a shrimp feed making machine specially developed by RICHI for producing shrimp feed pellet. It is equipped with three-layer modulator and can well meet the production needs of shrimp feed mill.

The price of shrimp feed pellet machine: $7,000-$100,000

Features of shrimp feed making machine:

Forging process

The main components are forged to ensure greater hardness and longer service life.

Modulator

Equipped with three-layer modulator, modulator types are optional: differential modulator, quality control device, etc.

Humanized design

Such as safety pin assembly, observation port, etc. Easy to operate, which can protect the safety of both the staff and the equipment.

Stainless steel

The modulator, ring die, etc. are made of stainless steel, which is corrosion-resistant, ensuring the quality of the finished pellet and extending the service life.

Motor

Equipped with 6P-8P motor, the power is increased, which can increase the capacity of shrimp feed pellet.

Pressure roller

Design special pressure roller for shrimp feed pellet and improve the original feeding scraper to make the material evenly distributed.

Shrimp feed pellet machine parameters

| Model | Capacity (t/h) | Main motor power (kw) | Feeder power (kw) | Conditioner power (kw) | Ring die diameter (mm) |

| SZLH250 | 1~2 | 22 | 1.1 | 1.5 | 250 |

| SZLH320 | 3~4 | 37 | 1.5 | 2.2 | 320 |

| SZLH350 | 5~7 | 55 | 1.5 | 3 | 350 |

| SZLH420 | 8~12 | 110 | 1.5 | 7.5 | 420 |

| SZLH508 | 10~18 | 160 | 2.2 | 11 | 508 |

| SZLH558 | 15~25 | 180/200 | 2.2 | 11 | 558 |

| SZLH678 | 20~30 | 220/250 | 2.2 | 11 | 673 |

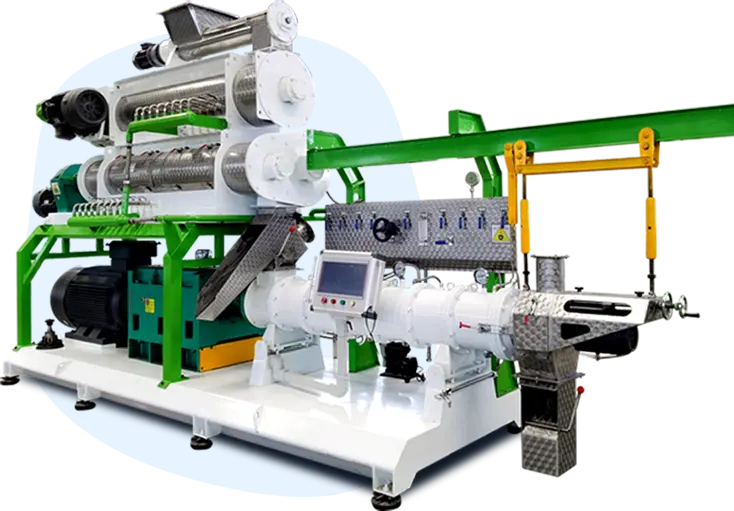

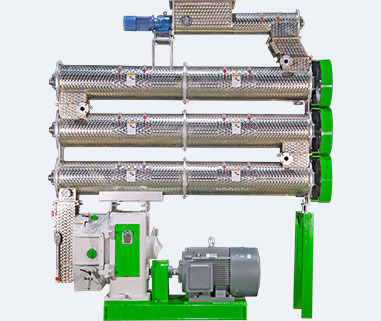

Shrimp Feed Extruder

— Richi Machinery —

RICHI shrimp feed extruder is suitable for shrimp feed mill that use extrusion technology to produce shrimp feed pellet. It can produce shrimp feed pellet with high oil content, strong water resistance and rich nutrition.

The price of shrimp feed pellet machine: $2,000-$100,000

Features of shrimp feed making machine:

High Capacity

The whole extruder has high output, good performance, low energy consumption and low noise.

Modulator

Adopt different diameter differential speed modulator, the modulation time is prolonged and the conditioning is sufficient.

Screw

Use the latest technology and new materials to process the screw to extend the service life of the screw.

Motor

Equipped with Siemens motor, the quality is more guaranteed.

automatic control

The entire equipment adopts a fully automatic control system, one person can operate multiple devices to improve production efficiency.

Inverter motor

The feeder adopts variable frequency motor to control the speed, and the speed can be adjusted freely.

Shrimp feed pellet machine parameters

| Model | Main Power(kw) | Dia. of Screw(mm) | Capacity(t/h) | Matching feeder model-power | Matching differential conditioner model-power |

| SPHS120*2 | 75 | 120 | 1~2 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS120*2 (6.6*1.6*4M 6T) | 90 | 120 | 3~4 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS150*2 | 160 | 150 | 4~5 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS 150*2 (8*2*4.3M 8T ) | 200 | 150 | 6~7 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS185*2 | 315 | 185 | 8~10 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

| SPHS185*2 | 355 | 185 | 10~12 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

Richi Machinery

How does the Shrimp Feed Machine work?

When shrimp feed pellet machine and shrimp feed extruder are used to produce shrimp feed pellet, the working principle is completely different:

The shrimp feed pellet machine mainly uses the extrusion effect of the ring die and the pressure roller to compact the material, then squeeze it into the membrane hole of the ring die to form it, and then be extruded to form shrimp feed pellets.

The shrimp feed extruder is discharged from the membrane holes through the extrusion, shearing and kneading action of the screw, and the volume increases instantly to form expanded feed pellets.

Customers can choose pelleting process or extrusion process to produce shrimp feed pellet according to actual production needs.

Application of Shrimp Feed Making Machine

— Richi Machinery —

RICHI shrimp feed making machine is suitable for using fish meal, soybean meal, soybean cake, peanut cake, wheat bran and other raw materials to produce South American shrimp feed pellet, Pacific white shrimp feed pellet, black tiger shrimp feed pellet, giant tiger shrimp feed pellet, red tail shrimp feed pellet, Macrobrachium rosenbergii feed pellet, etc.

Widely used in medium or large shrimp farming factories or shrimp feed mill.

Complete shrimp feed production process

— Richi Machinery —

When shrimp feed mill produce shrimp feed pellet, they usually use complete shrimp feed pellet line. Because using complete shrimp feed production line to produce shrimp feed pellet can significantly improve the production efficiency of shrimp feed pellet and the quality of shrimp feed pellet.

With rich experience, RICHI carefully designs complete shrimp feed pellet line for shrimp feed mill and creates turnkey shrimp feed production projects.

The process flow of a standard shrimp feed production line:

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

First crushing and mixing

Coarse crushing and mixing of materials that account for a large proportion of the shrimp feed formula

Second crushing

The material fineness requirement for shrimp feed production is relatively high, and it is generally crushed twice

Pelleting (needed for pelleting process)

Pelleting using shrimp feed pellet machine with a three-layer modulator

Extrusion (required for extrusion process)

Use the shrimp feed extruder produced by RICHI’s unique process to expand the material into shrimp feed pellets

Drying

To reduce the moisture content in feed pellets, drying machine is needed

Spraying

Use spraying equipment to spray the oil onto the surface and inside of the feed pellet

Cooling

Cool the shrimp feed pellets to room temperature to increase the hardness of the shrimp feed pellets

Packing

Use packing machine to pack shrimp feed pellets into 10-50 kg bags of feed

Auxiliary Display

— Richi Machinery —

In addition to shrimp feed pellet machine and shrimp feed extruders, RICHI can provide a complete set of equipment required in the shrimp feed production process, including hammer mill, ultrafine grinders, mixers, coolers, drying machine, spraying equipment, high square screens, packing machine, etc., as well as auxiliary equipment such as conveying equipment and dust removal equipment.

Hammer Mill

Ultrafine Grinder

Feed Mixer

Feed Extruder

Feed Cooler

Spraying Equipment

Belt Dryer

Feed Pellet Machine

Project of Shrimp Feed Production

— Richi Machinery —

The design concept of RICHI shrimp feed pellet machine and shrimp feed extruder has been verified on more than 1,000 machines worldwide, and has been applied to multiple shrimp feed production projects, and has been well received by customers.

At present, the feed production projects undertaken by RICHI are spread across more than 120 countries and regions around the world. RICHI always serves global customers with high-end quality.

3-4 t/h shrimp feed pellet line in Algeria

Feed type: Shrimp feed pellet

Major equipment:

Hammer mill SFSP 66*60,Silo,Feed Mixer 500KG/P,Ultrafine grinding equipment SWFL 130E,Square Plansifter,feed pellet machine,Feed Cooler,Packing machine,Steam boiler

Features of shrimp feed pellet line:

The shrimp feed production project is equipped with a shrimp feed pellet machine with a three-layer modulator, and the modulator adopts a different-diameter differential-speed modulator to extend the material modulation time and improve the material maturity. The external jacket device can play a role in heat preservation, making it difficult for the temperature in the modulator to dissipate, thereby improving the material modulation effect.

High-quality shrimp feed making machine combined with complete shrimp feed production auxiliary equipment can efficiently produce shrimp feed pellets with better quality.

2.5-5 t/h shrimp feed mill in Malaysia

Feed type: Shrimp Feed

Major equipment:

Main equipment: Hammer mill SFSP 66*60,Feed Mixer 500KG/P,Ultrafine grinding equipment SWFL 130E,Square Plansifter,feed pellet ectruder,Feed Cooler,Packing machine,Steam boiler

Features of shrimp feed mill:

Since the customer’s feed formula is quite special and considering the quality of the finished shrimp feed pellets, they finally decided to use the extrusion process to produce shrimp feed. Therefore, we equipped the shrimp feed production project with a twin-screw shrimp feed extruder to ensure the quality of the shrimp feed produced.

2 t/h shrimp feed production line in Indonesia

Feed type: Shrimp feed pellet

Major equipment:

Mixing machine SLHY.0.5A,Hammer mill SFSP56*40,Pellet machine SZLH420,Automatic Packing machine DSC-50

Features of shrimp feed production line:

Equipped with SZLH series shrimp feed making machine, the shrimp feed pellet machine is used to produce shrimp feed. The three-layer modulator on the shrimp feed pellet machine can meet the requirements of the maturation degree of the material.

According to the characteristics of the customer’s raw materials, feed hammer mill are used for both crushing processes, which can achieve the required crushing fineness and save costs.

2.5-5 t/h shrimp feed & 8-12 t/h sinking fish feed production line in India

Feed type: Shrimp Feed pellet, Sinking fish feed pellet

Major equipment:

Hammer mill SFSP66*100,Mixing machine 1000KG/P,Ultrafine grinding equipment SWFL 110C,Pellet machine SZLH420,Packing machine,Steam boiler

Features of feed production line:

The pelleting process is used to produce shrimp feed pellet, so a shrimp feed pellet machine with a three-layer conditioner is equipped. At the same time, this feed making machine can also be used to produce sinking fish feed, just need to change the type of raw materials. So this feed production plant can be used to produce fish feed in the off-season to improve the efficiency of the feed mill.

Customizable shrimp feed making machine

Each shrimp feed making machine is customized according to the specific needs of the customer, such as raw materials, capacity, production requirements, local production conditions, etc.

RICHI can customize shrimp feed making machine to meet the production needs of each user.

Frequently asked questions

do you have whole pellet line for shrimp? can you help with a quote?

In addition to a single shrimp feed pellet machine or shrimp feed extruder, we have a complete shrimp feed production line and can provide turnkey shrimp feed production projects.

We can provide the main equipment needed for the entire shrimp feed production project, such as hammer mill, shrimp feed machine, feed extruders, etc., as well as some auxiliary equipment, such as conveying equipment, dust removal equipment, etc.

As for the price of the entire shrimp feed production line, I need to understand your specific needs first, and then let our engineering designers customize a production plan for you. Only after the shrimp feed production plan is determined can we calculate the price for you.

Want to know more about the shrimp feed making machine price, please contact us immediately, we have a detailed price list.

I would like to produce shrimp feed pellets Can you help with the machine and how to produce these pellets?

As professional shrimp feed making machine manufacturer, first I need to know your capacity and raw materials, and then customize the shrimp feed production line solution for you according to your specific needs, equipped with corresponding shrimp feed making machine.

After the shrimp feed making machine is installed, we will debug your feed pellet machine to the best production status, provide professional knowledge training to your staff, and then test run the entire shrimp feed production line until your shrimp feed production line can produce shrimp feed pellets that satisfy you.

Therefore, if you want to start a shrimp feed production business, what you need most is to find a professional partner to cooperate with.

I want to produce South American shrimp feed. Do you have South American prawn feed making machine?

Of course, our prawn feed making machine can meet the production needs of a variety of prawn feeds, among which South American prawn feed is one of the main products of our prawn feed making machine.

One of our customers purchased a 2t/h complete prawn feed production line, which is mainly used to produce South American prawn feed pellets.

Therefore, our prawn feed making machine can fully meet your production needs. When you have an idea for prawn feed production, just contact us directly.

We have decided to establish a shrimp feed production line. I am grateful if you provide the information.

To build a shrimp feed production line, you need to consider many aspects, such as the output of the shrimp feed production line, the raw materials for producing shrimp feed, the construction of the shrimp feed mill, the investment budget of the shrimp feed plant, etc.

After deciding on the solution, you need to consider the construction of the plant according to the height and land area of the shrimp feed production line. Of course, your plant will also be taken into consideration when designing the shrimp feed production line.

The production of shrimp feed production equipment and the construction of the plant are carried out at the same time, which can save your time and enable the shrimp feed mill to be put into production as soon as possible.

Shrimp feed pellet line is a very important part of building a shrimp feed plant, so finding a professional shrimp feed making machine manufacturer means that your shrimp feed production project is halfway successful.