Customized Turnkey pet food Production Project

Pet Food Production Line

0.5-50 t/hour pet food production line solutions.

We can provide a full set of pet food production machine and turnkey projects pet food production line.

Introduction of pet food production line

— Richi Machinery —

Introduction

As global leading pet food making machine manufacturer, we have been committed to the research of pet feed production for many years. We can provide you with a full set of pet feed production machine, turnkey pet food production line projects, and customized solutions for pet feed mill plant.

Our experience and expertise enables us to provide you with comprehensive advice and worry-free service throughout your pet food production project.

Application : Produce pet food for cats, dogs, turtles, etc.

Raw materials: Corn, wheat, rice, fish meal, chicken, beef, vitamins, minerals and other additives

0.5-50

Capacity(ton/hour)

1-8

Feed pellet size(mm)

Advantages of floating fish feed mill

Customized Design

The pet feed mill plant can be customized according to the size of the plant and specific needs.

Modular Design

The entire process of the pet food production line is modular in design, and the production sections can be increased or decreased according to the raw materials used and special needs.

Automation

Fully automated, semi-automated, and manual production processes can be selected according to demand.

Rich variety of raw materials

Can process raw materials with high oil and high moisture content, enriching the variety of raw materials

One line for multiple uses

It can be used not only to produce pet food, but also various fish feeds as well as poultry and livestock feeds.

Turnkey Projects

We provide full-process services from the design of pet food production line to the production and installation of equipment.

Capacity

RICHI can build pet food production line and pet feed mill plant with different capacitys to meet the production needs of customers in different regions.

The most common solution is a turnkey project solution for a pet food production line of 0.5-20 tons. However, if you have any special requirements in terms of capacity, please contact us directly!

0.5 t/h Pet Food Production Line

1 t/h Pet Feed Production Line

1-2 t/h Pet Food Mill

3-4 t/h Dog Food Production Line

5-7 t/h Turnkey Projects Pet Food Production

10 t/h Pet Food Mill Turnkey Project

10-20 t/h Pet Food Production Line For Sale

Finished pet food

— Richi Machinery —

The pet food production line we design and the pet feed mill plant we build can produce pet foods of different shapes and sizes to meet the feeding needs of cats, dogs, turtles and some other pets.

Cat

Dog

Turtle

Hamster

Fox

Kitten

pet food production process

— Richi Machinery —

RICHI has always been at the forefront of feed pelleting and extrusion technology, and attaches great importance to the innovation of pet food production technology.

After communicating with many customers and continuously improving technology, we now have a complete set of production processes in the field of pet food production:

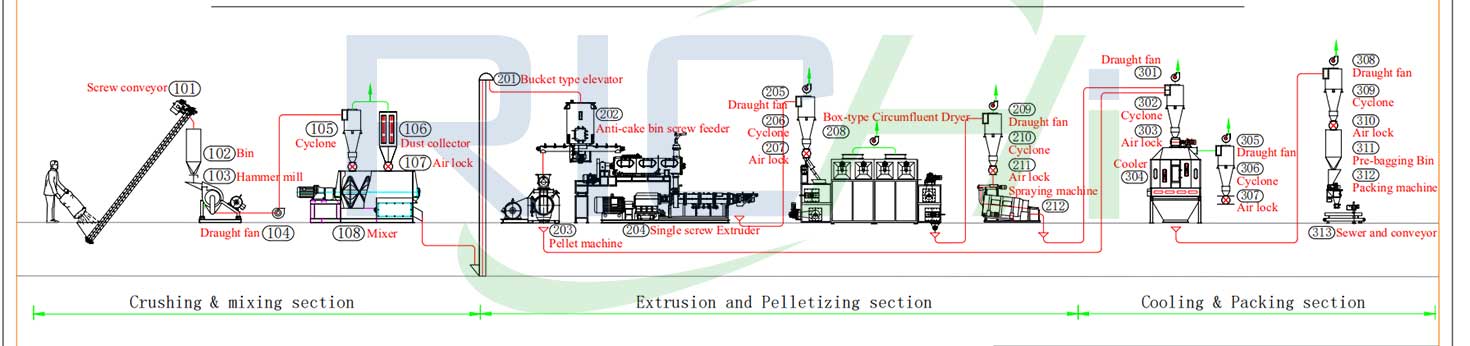

Receiving and processing of raw materials – first crushing and first mixing – second crushing – second mixing – extrusion section – drying section – spraying section – cooling section – packing section

Pet Food Production Line

This is the standard pet food production process. Each section is modular in design. Not every customer’s pet food production line needs to use all of the above sections. Sections can be added or reduced according to specific needs, and the equipment in each section will also be adjusted according to raw materials, output and other requirements.

All equipment on the pet food production line are customized. According to customer needs, a certain device on the food production line or the entire food production line can be made of stainless steel.

RICHI’s Footprints

— Richi Machinery —

RICHI has footprints in more than 120 countries and regions around the world, serving global customers with high-end quality; with more than 200 classic cases, it has become a leader in the field of feed making machine.

3-5 t/h pet food production line in Canada

Feed types: Dog food, cat food

Features of pet food production line:

The raw materials for this pet food production line are various grains such as corn, barley, oats, as well as chicken, beef, etc. that contain fat and protein.

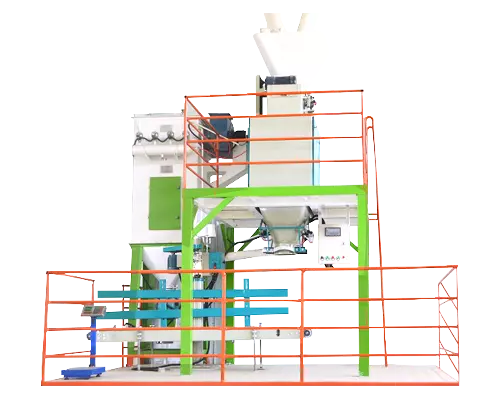

The entire pet food production line is equipped with automated equipment, from raw material receiving to finished pet food packing. Therefore, the entire pet food production line has a high degree of automation, which can greatly save labor in the subsequent production process, reduce the number of staff as much as possible, and improve production efficiency.

5 t/h pet feed mill plant in Russia

Feed types: Cat food, dog food and other pet food

Features of pet feed mill plant:

After the customer contacted us, he visited our poultry feed production project in Russia and was quite impressed with feed pellet machine, so he came to our factory to inspect our production workshop and the existing equipment in the workshop. After that, we had a face-to-face meeting and reached this cooperation.

The customer purchased a pet food production line from us, including a crusher, mixer, pet food extruder machine, dryer, cooler, sprayer, packing equipment, etc., as well as some conveying black blankets, dust removal equipment, screening equipment and other auxiliary equipment.

2.5 t/h pet food production line in Germany

Feed types: Mainly used to produce cat food, dog food and other pet food

Features of pet food production line:

2.5 tons per hour pet food production line was exported to Germany. The equipment required for the entire pet food production line is made of stainless steel and can produce high-quality pet food.

The pet food production line is equipped with a special pet food extruder machine developed by RICHI, which can be used for a variety of raw materials, including high-fat and high-moisture raw materials, to meet the production needs of a variety of pet food.

5 t/h pet feed mill plant in China

Feed types: Cat feed, dog feed, chicken feed, pig feed, etc.

Features of pet feed mill plant:

The fully automatic pet food production line is mainly used to produce pet food for cats, dogs, turtles, etc., but it will also produce some feed suitable for poultry and livestock such as chickens and pigs according to market demand. Therefore, we specially design the entire feed production line according to this customer demand.

This food production line is a turnkey food production project. We complete everything from the design of the production line to the planning of the plant and the installation of equipment.

Customized pet food production line design

— Richi Machinery —

Customized solutions can help different customers achieve their unique business needs, improve efficiency and reduce costs.

All of our pet food production lines are custom designed. We customize pet feed mill plant to meet the needs of customers based on the different raw materials, site size and height restrictions, automation requirements, and production requirements.

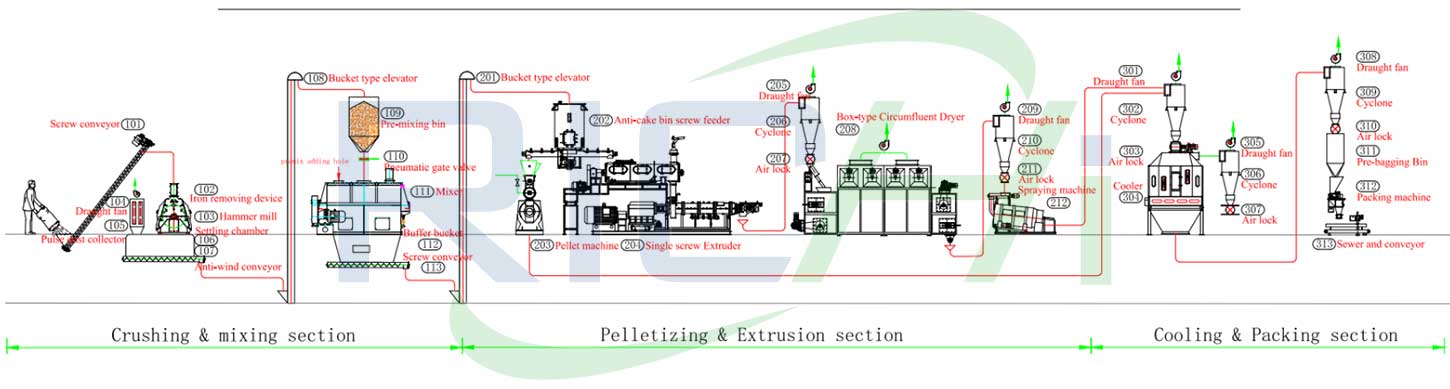

1-2 t/h pet & poultry food production line

Type of Feed Produced: Pet food, chicken feed, pig feed, etc.

Process flow: Crushing and mixing section – extrusion (pelleting) section – cooling and packing section

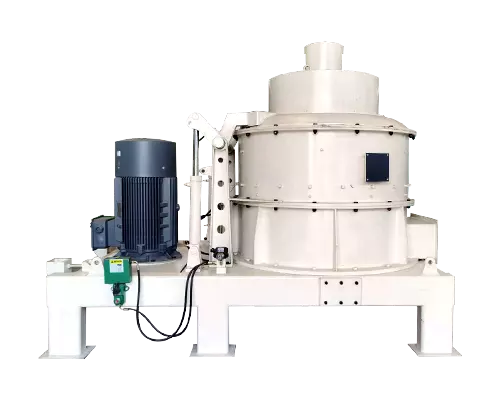

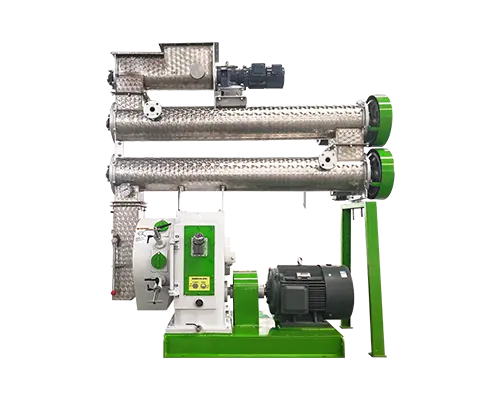

Main equipment used: Hammer mill, mixer, feed extruder machine, feed pelletizer, belt dryer, sprayer, cooler, packing equipment

3 t/h pet food & 5-6 t/h poultry feed production line

Type of Feed Produced: Pet food, extruded fish feed, chicken feed, etc.

Process flow: Crushing and mixing section – extrusion (pelleting) section – cooling and packing section

Main equipment used: Hammer mill, feed mixer, feed pelletizer, pet food extruder machine, drying machine, spraying equipment, cooler, packing equipment

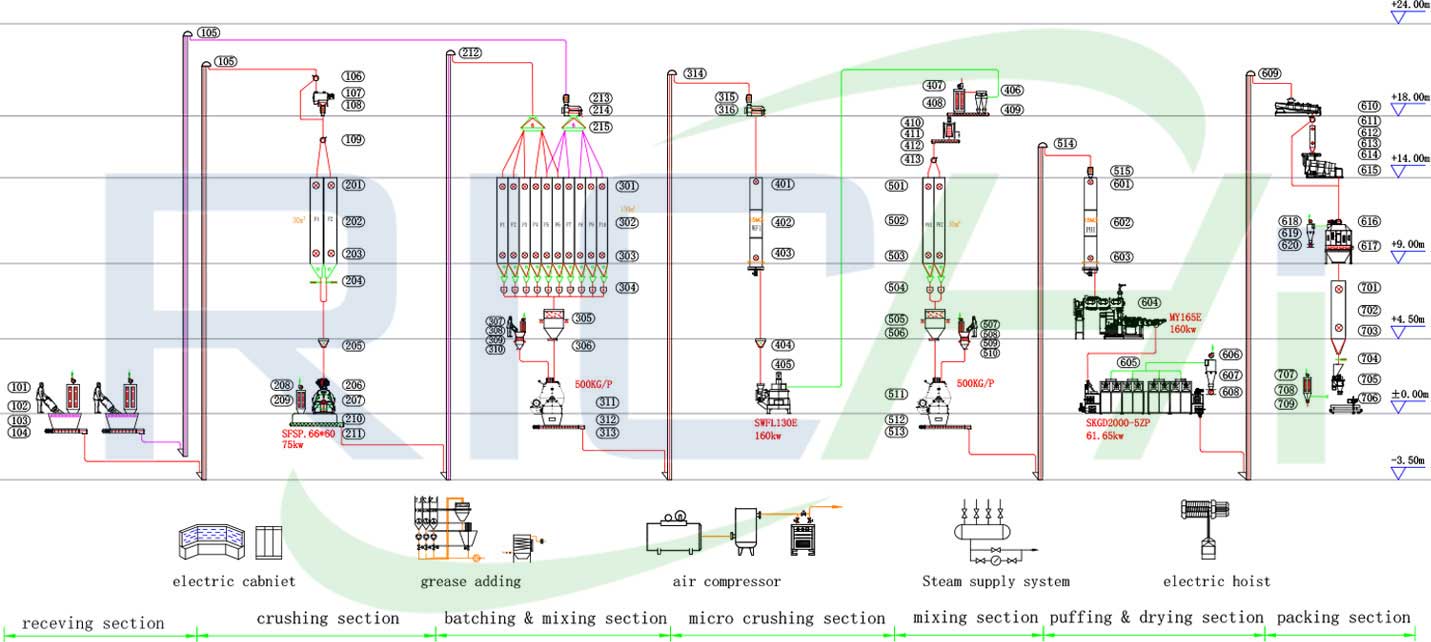

5 t/h pet feed mill plant

Type of Feed Produced: Cat food, dog food and other pet food

Process flow: Receiving of raw materials – crushing section – batching and mixing section – ultrafine crushing section – second mixing, extrusion, drying section – packing section

Main equipment used: Hammer mill, silo, batching scale, ultrafine grinder, pet food extruder machine, belt dryer, cooler, rotary grading screen, high square screen, packing equipment

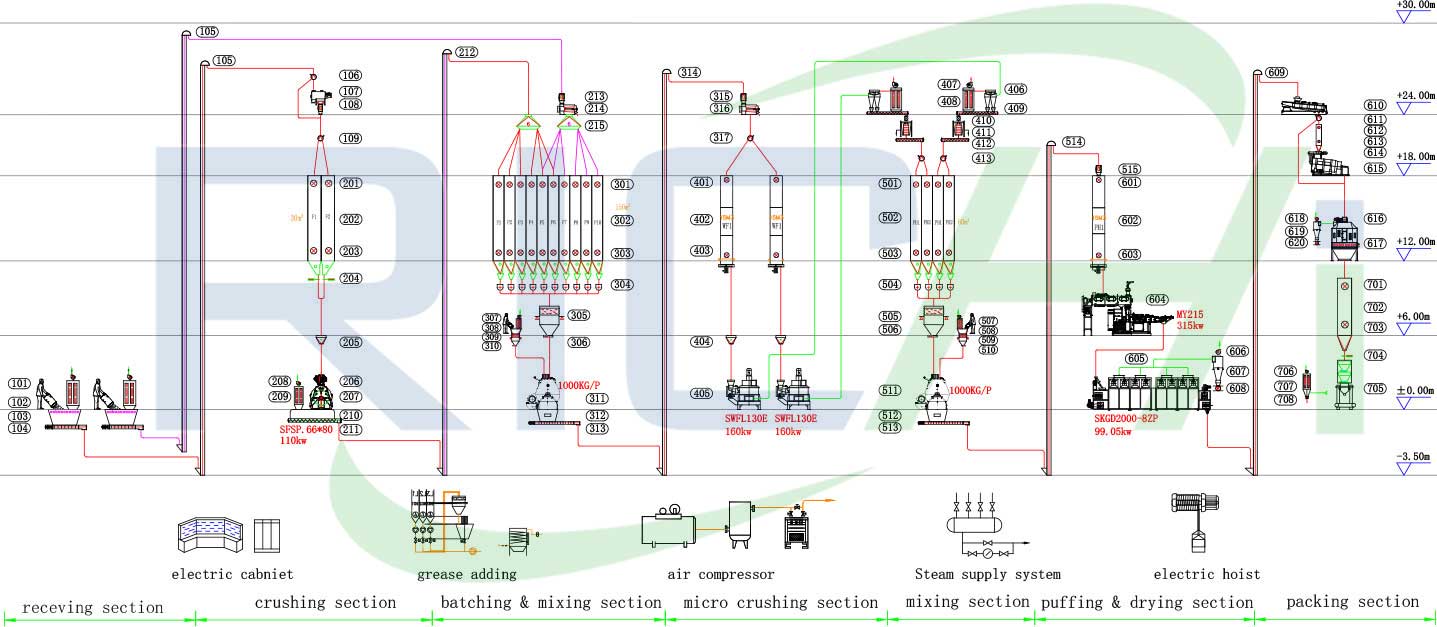

10 t/h pet & fish feed production line

Type of Feed Produced: Cat food, dog food and other pet food, extruded fish feed

Process flow: Receiving of raw materials – crushing section – mixing section – ultrafine crushing section – second mixing section – extrusion and drying section – packing section

Main equipment used: Hammer mill, ultrafine grinder, mixer, pet food extruder machine, belt dryer, rotary grading screen, packing equipment, steam boiler, dust removal equipment

Frequently Asked Questions

I want to produce pet food, fish feed and poultry feed. Is this possible on one feed production line?

Of course, as a professional feed production machine manufacturer, we can design a feed production line for you that can produce a variety of feeds according to your actual production needs.

Many of the equipment on the feed production lines used to produce pet food, fish feed, and poultry feed overlap, such as grinders, mixers, dust removal machines, etc., so these equipment can be shared, but in order to meet the production needs of various feeds such as pet food and poultry feed, it is necessary to equip feed pelletizer and food extruder machine at the same time.

The composite feed production line we designed can not only meet the needs of customers to produce a variety of feeds, but also save investment costs. It is very suitable for customers with a variety of feed production needs.

What are the benefits of using extrusion equipment to produce pet food?

The pet food production line designed by RICHI specifically for the production of pet feed is equipped with feed extruder machine, including single-screw extruder machine and twin-screw extruder machine.

Nowadays, people prefer to use feed extruder machine to produce pet food, mainly for the following reasons:

*Extrusion equipment can improve the palatability of pet food. After extrusion, the pet food becomes crispy and tastes better;

*Extrusion can improve the nutritional value of pet food. Many nutrients in the raw materials used to produce pet food need to be cooked and extruded to achieve the best nutritional value, otherwise pets will have symptoms such as diarrhea after eating;

*During the extrusion process, various molds and other harmful substances in the raw materials are killed by high temperature and high pressure.

Please can i have a quotation for pellet machines for animal feed?

The first question many customers ask us is the price. As a professional pet feed mill plant manufacturer, we have professional quotations, but the prices of different feed pellet machine are different. For example, the prices of feed production machine with different capacitys are very different.

So if you want to know the price of feed pellet machine please tell us your specific needs, such as capacity, raw materials, etc.; if you are not sure about your specific needs, you can directly leave your contact information and the price you want to know. Our professional sales manager will contact you within 24 hours to communicate with you about the equipment you need, and give you professional advice and quotations.

If I want to produce both floating fish feed and sinking fish feed pellet, do I need to purchase two feed production lines to meet my production needs?

No. Some feed mills only produce a single type of feed, such as sinking fish feed, floating fish feed, shrimp feed, chicken feed, cattle feed, etc.; there are also a large number of feed mills that produce multiple types of feed at the same time, which is what we call a compound feed pellet mill.

A compound feed pellet mill does not need to be equipped with two completely different feed production lines, because many equipment can be shared, such as grinders, mixers, coolers, packing machine, etc., as well as auxiliary equipment on the feed production line, can all be shared.

Therefore, you only need to equip different feed pellet machines, feed extruders, etc. according to specific production needs to achieve the purpose of producing a variety of feeds, without the need to purchase two complete feed production lines.