Pet Food Extruder Machine

High Quality Pet Food Extruder Machine

Customized Pet Food Feed Production Solutions

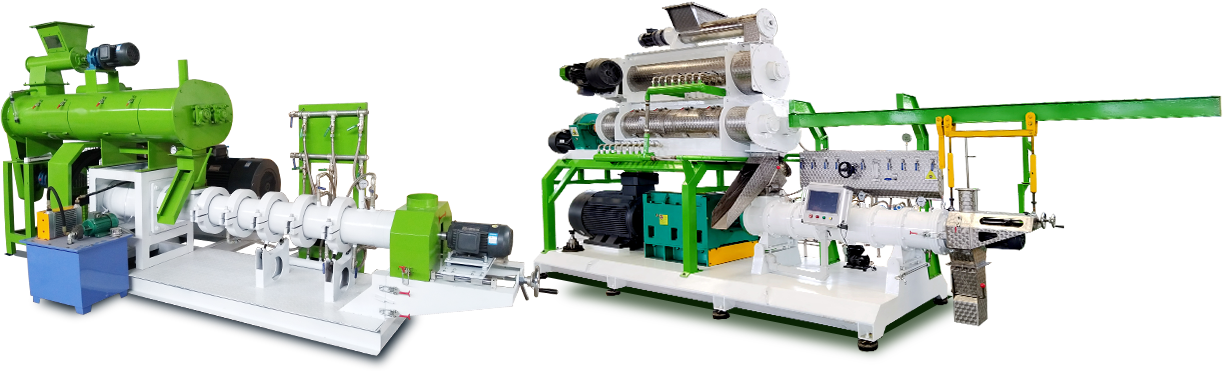

Pet Food Extruder

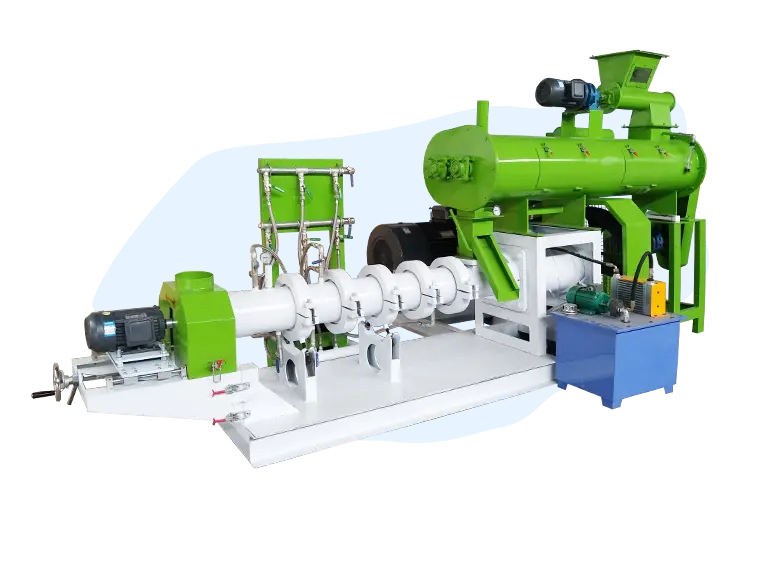

Single screw pet food extruder machine

RICHI pet food extruder machine can be used to produce high-quality pet feed in different shapes for cats, dogs, turtles, etc., to meet the needs of pet owners for pet food due to the rapid development of the pet market. Among them, the single screw pet food extruder machine is a more common pet feed production equipment.

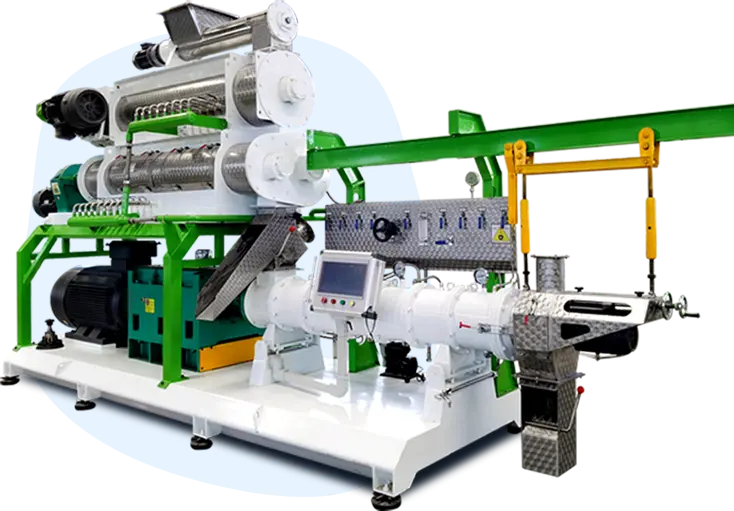

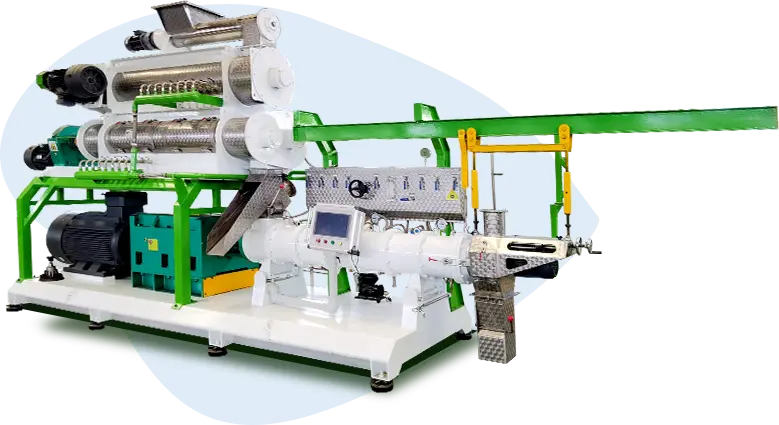

Twin screw pet food extruder machine

The twin screw pet food extruder machine developed by RICHI can meet the production needs of pet feed to the greatest extent.

At the same time, we can provide a full range of pet food extruder machine with full capacity according to the actual needs of customers, and help the development of the pet feed mill plant.

Single screw pet food extruder machine

— Richi Machinery —

RICHI single screw pet food extruder machine can be used to produce pet food for cats, dogs, etc. It is suitable for small capacity pet food production line, such as small capacity pet feed mill plant with relatively small investments.

Single screw pet food extruder machine price: $2,000-$60,000

SKF bearings

The bearings in the transmission box are made of SKF bearings, which can ensure long-term stable operation.

Fully automatic control

Fully automatic control system enables one person to control multiple machines, thus improving labor productivity.

Large output

Effectively distribute the reasonable shear force in different areas of the extrusion cavity, effectively increasing the output while ensuring high quality.

Feeding system

The feeding system adopts a uniquely designed silo with no sediment to ensure smooth feeding.

Single screw pet food extruder machine parameters

| Model | Capacity | Machine Power | Feeding Power | Dia. of Screw | Cutting Power |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

Twin screw pet food extruder machine

— Richi Machinery —

Twin screw pet food extruder machine can be used to produce high-grade pet food, especially for the efficient expansion of viscous materials in feed formulas. They are suitable for pet food production plants of all capacitys.

Twin screw pet food extruder machine

price: $2,000-$100,000

Features of twin screw extruder machine:

Screw

Adopt new wear-resistant alloy screw and bimetal expansion chamber sleeve to effectively reduce wear.

SKF bearings

The bearings in the transmission box are made of SKF bearings to ensure long-term stable operation.

uniformity of material maturation

Steady-state screw structure fully improves the uniformity of material maturation in the screw.

High standard accessories

All accessories are made of international advanced standards, which effectively improves the running stability of the equipment and effectively controls the noise.

Twin screw pet food extruder machine parameters

| Model | Main Power(kw) | Dia. of Screw(mm) | Capacity(t/h) | Matching feeder model-power | Matching differential conditioner model-power |

| SPHS120*2 | 75 | 120 | 1~2 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS120*2 (6.6*1.6*4M 6T) | 90 | 120 | 3~4 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS150*2 | 160 | 150 | 4~5 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS 150*2 (8*2*4.3M 8T ) | 200 | 150 | 6~7 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS185*2 | 315 | 185 | 8~10 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

| SPHS185*2 | 355 | 185 | 10~12 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

Richi Machinery

How does the pet food extruder work?

The general process of using RICHI pet food extruder machine to produce pet food is as follows: the crushed material enters the modulator through the feeder, saturated hot steam is introduced into the modulator, the material and saturated hot steam are evenly mixed in the modulator, and after reaching a certain temperature and moisture, it enters the extrusion system, and is extruded, kneaded, sheared, etc. under the action of the screw, and finally extruded from the die, and the pet feed is expanded at the moment of extrusion, and then cut into feed particles of the desired length by the cutter.

Application of pet food extruder machine

— Richi Machinery —

Our pet food extruder machine can meet all feed production needs of the pet feed mill plant, including applicable pet feed types, such as common cats, dogs, as well as hamsters, turtles, rabbits, etc. Pet foods of different shapes can meet the feeding needs of different pets.

It is suitable for all kinds of small, medium and large pet food production plants, and can help existing feed mill plant open the entrance to pet food production.

Complete pet food extruder production process

— Richi Machinery —

Pet food extruder machine usually do not operate alone, but together with hammer mill, feed mixers, coolers, etc., they form a complete pet food production and processing system to achieve precise processing of pet feed, improve the quality of pet feed, and increase its market value.

The process flow of the standard pet food production line is (Not every pet feed mill plant needs to be equipped with all of the following sections. All sections on our pet food production line are modular in design and can be increased or decreased according to your actual needs):

Receiving and handling of raw materials

Receiving, processing and storing raw materials according to feed formula

First crushing and first mixing

Coarse crushing and first mixing of raw materials

Second crushing

Crushing again to make the material finer and easier to extrude

Second mixing

All materials and small materials that need to be added are fully mixed

Extrusion

The crushed material is formed into feed pellets through pet food extruder machine

Drying

Dry the pet food pellets with high moisture content to a moisture content of 10%-11% for easy storage

Spraying

Spray oil or seasoning on the surface of feed to increase palatability

Cooling

Cool to room temperature to increase the hardness of pet food pellet

Packing

Packed into 10-50 kg bagged pellets for easy storage, use or sale

Auxiliary Display

— Richi Machinery —

RICHI can provide all the feed production equipment needed in the entire pet food production project. In addition to single screw pet food extruder machine or twin screw pet food extruder machine, we can also provide hammer mill, feed mixers, coolers and other related equipment.

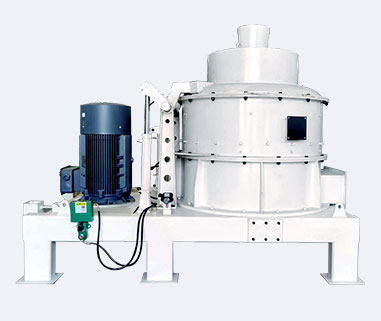

Hammer Mill

Ultrafine Grinder

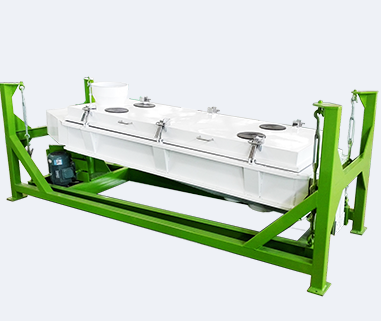

Feed Mixer

Feed Extruder

Dryer Machine

Spraying Equipment

Square Plansifter

Rotary Screener

Project of pet food Production

— Richi Machinery —

After nearly three decades of development and continuous technological improvement, RICHI pet food extruder machine has been used in many pet food production projects around the world.

2.5 t/h pet food production line in Canada

Feed type: Dog food, cat food, bird food

Major equipment:

Hammer mill,Mixer,Twin screw extruder,Box-type Circumfluent Dryer,Vacuum spray equipment,Cooler,Packing machine,Grease adding tank

Features of pet food production line:

This is a pet food production line purchased by a well-known brand in the pet-related industry in Canada, aiming to improve the quality of local pet food. We equipped this pet food production line with a twin-screw pet food extruder machine made of stainless steel to ensure the quality of the finished feed pellets.

The project is mainly used to produce dog food, followed by cat food and a small amount of bird food.

1 t/h pet feed mill plant in Mexico

Feed type: Dog food, cat food

Major equipment:

Hammer mill,Mixer,Single screw extruder,Box-type Circumfluent Dryer,spraying equipment,Cooler,Packing machine

Features of pet feed mill plant:

Located in Querétaro, Mexico, the project is equipped with single screw pet food extruder machine and uses a wet granulation process to produce pet food. The pet food extruder machine, drying equipment, spraying equipment and grease adding tank are made of stainless steel. In addition, the entire feed production line is made of high-quality carbon steel.

3-5 t/h livestock and pet food production line in Russia

Feed type: Dog food, cat food

Major equipment:

Twin screw pet food extruder machine,Vacuum spray equipment,Box-type Circumfluent Dryer

Features of livestock and pet food production line:

This customer has its own feed production plant, which is mainly used to produce livestock and poultry feed. After seeing the market and development potential of pet food, it decided to increase the production of pet food on the basis of livestock and poultry feed.

Therefore, based on his original equipment, we equipped him with a twin-screw pet food extruder machine, a vacuum sprayer and some related auxiliary equipment, which achieved the purpose of pet food production while saving costs and space.

2.5-5 t/h pet feed and aqua feed mill plant in Indonesia

Feed type: Dog food, cat food, floating fish food

Major equipment:

Hammer mill,Mixer,Twin screw pet food extruder machine,Box-type Circumfluent Dryer,Ultrafine Grinder,Vacuum spray equipment,Cooler,Packing machine,Grease adding tank

Features of pet feed and aqua feed mill plant:

Equipped with twin-screw pet food extruder machine, ultra-fine grinder and vacuum spraying equipment, it can be used to produce both pet feed and floating fish feed.

In addition, the entire feed production line has a high degree of automation and is equipped with a centralized control system, using computer batching, extrusion, and vacuum spraying with independent touch screen controls.

Pet food extruder machine can be customized design

The capacity and details of all pet food extruder machine of RICHI can be customized, such as the modulator can be customized, the voltage of the food extruder machine can be customized, the capacity can be customized, etc.

We specialize in providing our customers with the pet food extruder machine that best suits their needs!

Frequently asked questions

What is the difference between dry extrusion and wet extrusion when producing pet food?

The main difference between dry extrusion and wet extrusion is that the wet extrusion food extruder machine is equipped with a modulator and requires saturated hot steam to be introduced during the working process.

Dry extrusion is mainly used in the production of pet food with small capacity and low investment. Compared with dry extrusion, wet extrusion can improve the quality of pet food pellet and increase the capacity of pet food to a certain extent.

However, whether to choose dry extrusion or wet extrusion to produce pet food still requires comprehensive consideration.

Where can I buy your pet food extruder machine?

RICHI is a professional feed pellet machine manufacturer. You can contact us directly through WhatsApp, email, online chat or message. After seeing your needs, we will let professional engineers reply you within 24 hours.

All feed production machine is manufactured in our own factory and then shipped directly from the factory to your project location.

I want to buy pet food extruder machine, can you tell me the price of pet food extruder machine?

RICHI provides a full range of pet food extruder machine with full production capacity, with prices ranging from US$7,000 to US$100,000.

The prices of pet food extruder machinewith different capacity different design and different materials are completely different, so please contact us and tell us your specific needs directly, and we can send you a detailed reference price. Of course, you can also tell us your budget, we have pet food extruder machine price list, which can be sent to you for reference.

Can I produce pet food in different shapes using your pet food production equipment?

Of course, according to the market demand and the pet’s feeding needs, we can produce pet food in various shapes such as heart, five-pointed star, crescent, etc.

In addition, if you produce cylindrical pelleted feed, you can produce pet feed pellets of different sizes and a certain length according to customer needs.