Customized Turnkey Fish Feed Production Project

floating fish feed production line

0.5-20 t/hour floating fish feed production line solutions.

We can provide a full set of floating fish feed production machine and turnkey projects floating fish feed production line.

Introduction of floating fish feed production line

— Richi Machinery —

Introduction

As world-leading floating fish feed machine manufacturer, we have been deeply involved in the field of floating fish feed production for nearly 30 years. We can provide you with a full set of floating fish feed machine and a turnkey floating fish feed production line projects, which can be used to process high-fat and high-moisture raw materials, providing ideal aquatic feed pellet production solutions for various farms and feed mills.

Our experience and expertise enables us to provide you with comprehensive advice and hassle-free service throughout your floating fish feed pellet production project.

Application : It can produce fish feed for tilapia, trout, catfish, eel, salmon, herring, ornamental fish, etc.

Raw materials: Rice bran, bean cake, silkworm pupa powder, bran, fish meal, barley flour, cornmeal, vitamins, bone meal, etc.

0.5-20

Capacity(ton/hour)

0.6-4

Feed pellet size(mm)

Advantages of floating fish feed mill

Customized Design

The floating fish feed mill can be customized according to the size of the plant and specific needs

Modular Design

The entire process of the fish feed production line is modular in design, and the production sections can be increased or decreased according to the needs.

Automation

Fully automated, semi-automated, and manual production processes can be selected according to demand.

Rich variety of raw materials

The extrusion process can process raw materials with high oil and high moisture content, enriching the variety of raw materials.

One line for multiple uses

It can be used not only to produce floating fish feed, but also shrimp feed, pet feed, poultry and livestock feed.

Turnkey Projects

We provide full-process services from the design of floating fish feed production line to the production and installation of equipment.

Capacity of floating fish feed production line

RICHI can build floating fish feed production lines and floating fish feed pellet mill with different capacitys to meet the feed pellet production needs of customers in different regions.

The most common solution is the turnkey project solution of 0.5-20 tons/hour floating fish feed production line, but if you have any special requirements in terms of capacity, please contact us directly!

1 t/h floating fish feed production line

Small floating fish feed production line can meet the investment of large fish farms or small and medium floating fish feed mill.

5 t/h floating fish feed mill

According to the development of local aquaculture industry and the market demand for fish and shrimp feed pellet, it can meet the investment needs of investors with medium or large floating fish feed mill.

0.5 t/h

1-2 t/h

3-5 t/h

10 t/h

10-18 t/h

Finished floating feed pellet

— Richi Machinery —

The floating fish feed production lines that we design and the floating fish feed plants that we build can be used to produce floating aquatic feed to meet the breeding needs of tilapia, trout, catfish, eel, salmon, herring, ornamental fish and other fish.

Tilapia

Trout

Eel

Catfish

Ornamental fish

Sturgeon

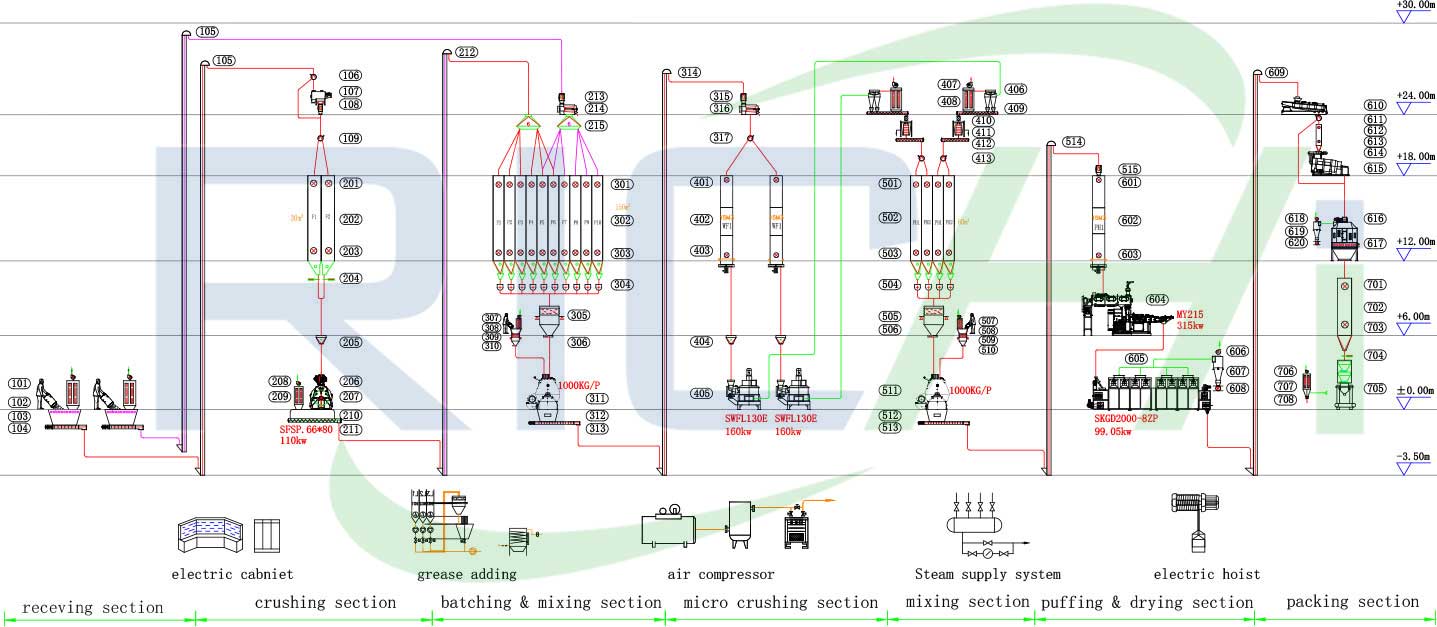

Floating fish feed production process

— Richi Machinery —

RICHI has always been at the forefront of technology and attaches great importance to the innovation of floating fish feed production technology.

After communicating with many customers and continuously improving the technology, we now have a complete set of production processes in the field of floating fish feed production:

Floating Fish Feed Line

This is the standard floating fish feed production process. Each process is modular in design. Not every customer’s floating fish feed production line needs to use all of the above processes. The process sections can be increased or decreased according to specific needs. The equipment in each process section will also be adjusted according to the needs of raw materials, capacity, etc.

RICHI’s Footprints

— Richi Machinery —

RICHI has footprints in more than 120 countries and regions around the world, serving global customers with high-end quality; with more than 200 classic cases, it has become a leader in the field of feed making machine.

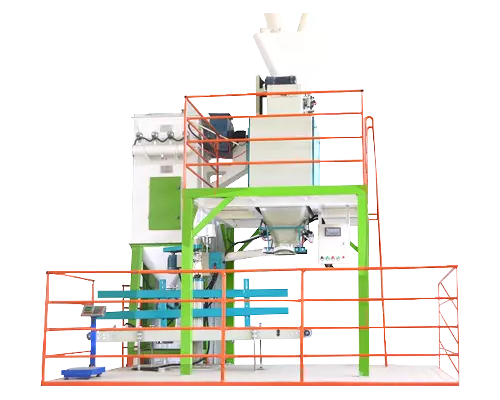

2 t/h floating fish feed production line in Indonesia

Feed types: Floating aquafeed, mainly fish feed

Features of floating fish feed production line:

The fat content of the raw materials in the customer’s feed formula is relatively high, so a twin-screw extruder was selected, and the extruder was equipped with a differential speed modulator.

The customer chose the fully automatic packing system, which greatly improved production efficiency.

3-5 t/h fish and poultry feed production line in India

Feed types: Floating fish feed, poultry and livestock feed

Features of feed production line:

The main feed pellet machine of the feed mill is equipped with feed extruders and feed pelletizers, which can be used to produce floating fish feed pellets in the peak season and poultry feed pellets or livestock feed pellets in the off-season. The feed mill is maximized, thereby improving its efficiency. From a long-term development perspective, it can greatly save the construction costs of feed mills.

1.5-2 t/h fish and shrimp feed mill in Iran

Feed types: Shrimp feed, floating fish feed and sinking feed

Features of feed mill:

The project is located in Iran, and the feed mill is equipped with both The project is located in Iran. The feed mill is equipped with both pelletizers and extruders, so it can be used to produce fish and shrimp feed pellet as well as poultry and livestock feed pellets.

Since the customer’s project site had height requirements, we eventually changed the feed production line from more than 20 meters high to 8 meters high.

5 t/h fish and shrimp feed mill in China

Feed types: Floating fish feed, sinking fish feed, shrimp feed

Features of shrimp feed mill:

By changing the starch content in the formula and replacing the screw in the feed extruder machine, the feed mill can use the fish feed extruder machine to produce floating fish feed as well as sinking fish feed and shrimp feed.

The use of a vacuum sprayer allows the grease to be sprayed into the interior of the extruded feed pellet, increasing the grease content and the uniformity of the grease spraying.

Customized floating fish feed production line design

— Richi Machinery —

Customized solutions can help different customers achieve their unique business needs, improve efficiency and reduce costs.

All of RICHI’s floating fish feed production lines are customized. We tailor professional floating fish feed mill for customers based on different raw materials, site size and height restrictions, automation requirements, and production needs.

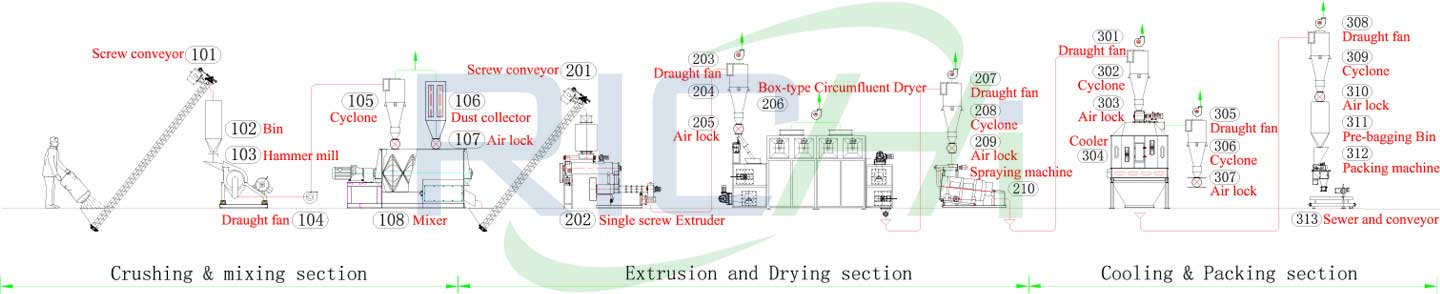

0.5 ton floating fish feed production line

Type of Feed Produced: Floating feed for aquatic organisms

Process flow: Crushing system – Mixing system – Extrusion system – Drying system – Cooling system – Packing system

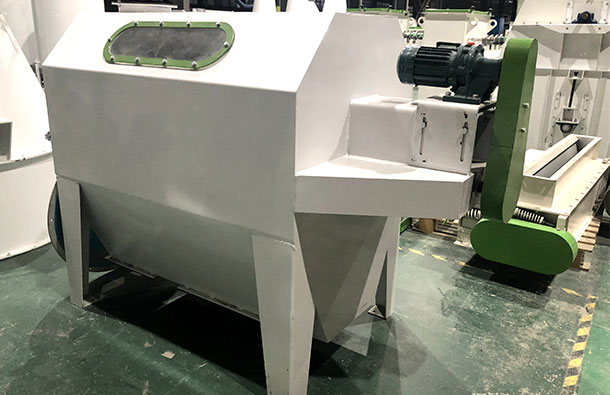

Main equipment used: Crusher, Mixer, Single screw extruder, Drying machine, Screening equipment, Cooler, Packing machine

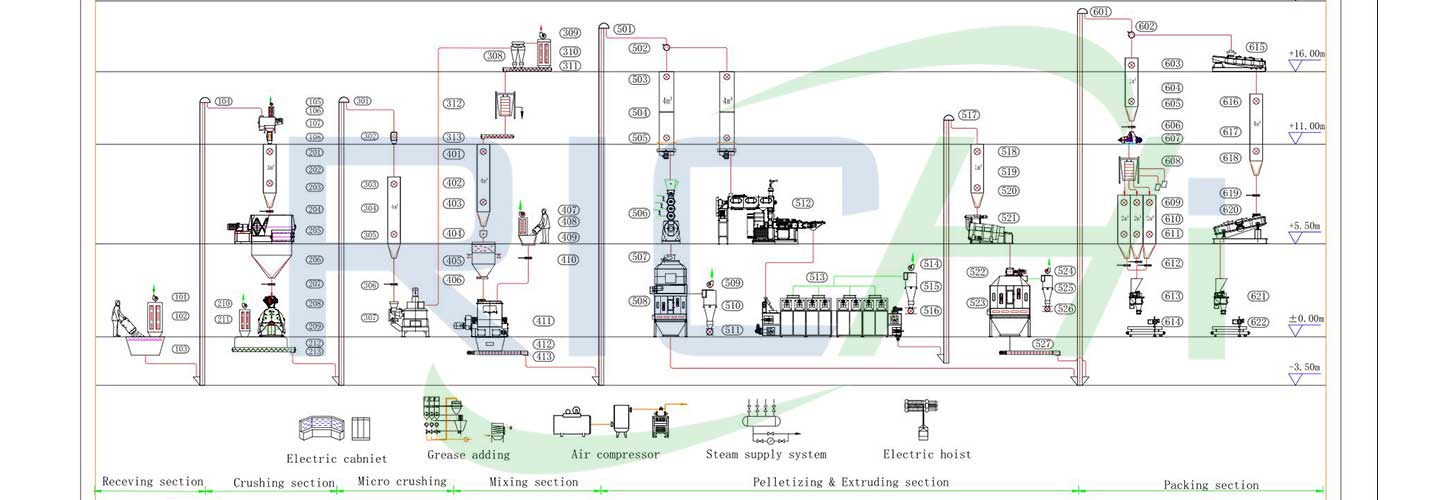

5 T/H shrimp feed & 2 T/H floating fish feed mill

Type of Feed Produced: Shrimp Feed, Floating Fish Feed

Pelleting process: Raw material receiving – Crushing system – Mixing system – Pelleting system – Cooling system – Packing system

Extrusion process: Raw material receiving – Crushing system – Mixing system – Extrusion system – Drying system – Cooling system – Packing system

Main equipment used: Hammer mill, Ultrafine grinder, Mixer, Feed pelletizer, Feed extruder machine, Drying machine, Cooler, Packing machine

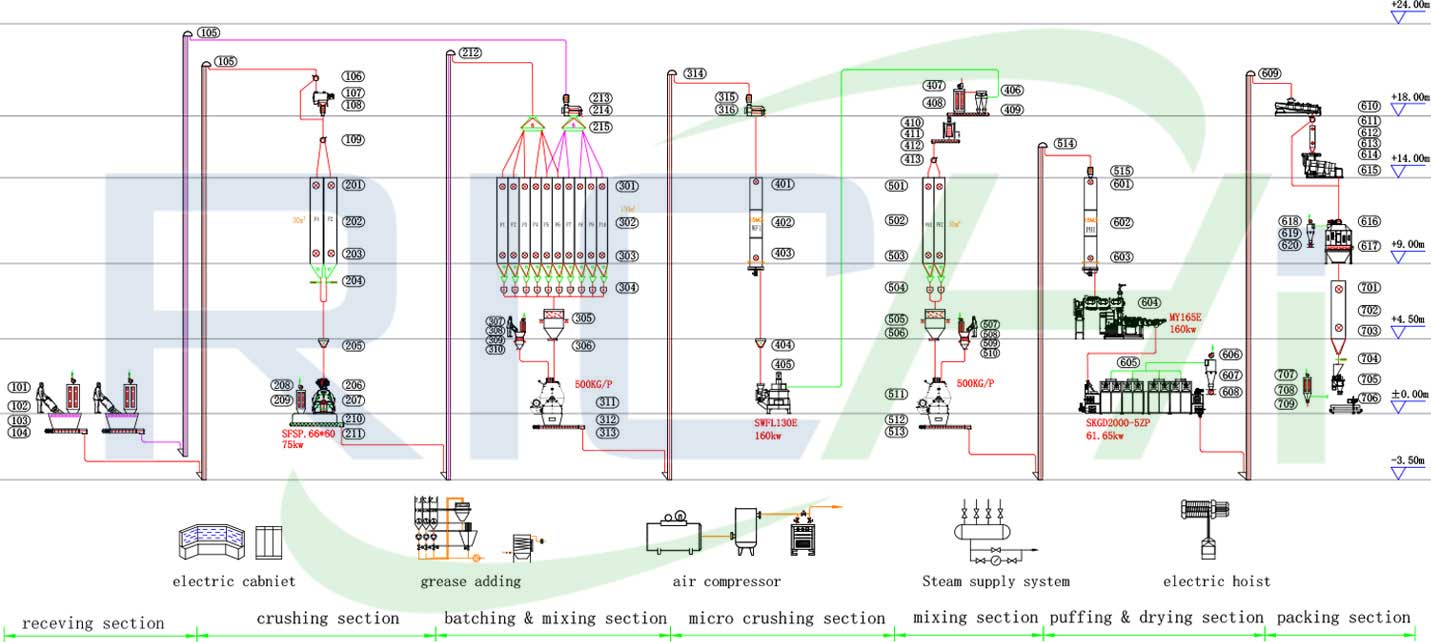

5 T/H floating fish feed production line

Type of Feed Produced: Mainly floating fish feed

Process flow: Raw material receiving – First crushing – Batching and first mixing – Second crushing – Second mixing – Extrusion – Drying – Spraying – Cooling – Packing

Main equipment used: Hammer mill, Silo, Mixer, Ultrafine grinder, High square sieve, Feed extruder, Drying machine, Vibrating screen, Spraying equipment, Packing machine

10 T/H floating fish feed production line

Type of Feed Produced: Mainly floating fish feed pellet

Process flow: Raw material receiving – Coarse crushing – Batching and first mixing – Second crushing – Second mixing – Extrusion – Drying – Spraying – Cooling – Packing

Main equipment used: Hammer mill, Silo, Batching scale, Mixer, Powder cleaning and drying, Ultrafine grinder, High square sieve, Fish feed extruder machine, Vibrating screen, Cooler, Packing equipment

Frequently Asked Questions

Customized solutions can help different customers meet their unique business needs, improve efficiency, and reduce costs.

All of Ruiqi’s floating fish feed production lines are custom designed. Tailored professional floating fish feed production plants

Why use extrusion technology to produce extruded feed?

Firstly, the floating fish feed after extrusion can float on the water surface and can meet the feeding habits of fish growing in the middle and upper layers. On the other hand, it is convenient to observe the amount of food eaten by fish. If there is residual aquatic feed on the water surface, it means that the feed fed last time has not been eaten up.

Secondly, compared with pelleted feed, extruded aquatic feed has a higher degree of maturity and is more conducive to fish absorption.

Why is the degree of maturity higher when using an fish feed extruder machine than feed pelletizer?

The feed pelletizer forms pellets by squeezing between a roller and a ring die. The highest temperature of the feed pellets after extrusion is only 90 degrees. However, the material in the extrusion chamber can reach 140 degrees during extrusion. For a twin-screw fish feed extruder machine, the temperature can reach 200 degrees at high temperatures.

In addition, the screw continuously shears the materials during rotation, and there will also be frictional shear force, which will also help the maturation of the materials to a certain extent.

How can we produce high-quality extruded feed?

In order to obtain better quality extruded floating feed, every link of feed production is very important, among which there are several important points to note:

First, the raw materials should be finely ground. The finer the raw materials are ground, the easier it is to mix the raw materials with steam in the modulator and to extrude the raw materials in the extrusion chamber, making it easier to obtain extruded feed with a smooth surface and uniform color.

Secondly, a reasonable formula is the key factor in producing high-quality extruded feed, especially the starch content in the raw materials, because the starch content is the key factor that determines the buoyancy and sinking properties of the extruded feed.

In addition, whether to choose spraying equipment and the choice of sprayer. Spraying can significantly increase the oil content of extruded feed pellet, and the effects brought by different spraying equipment are different. For example, the spraying effects brought by roller sprayers and vacuum sprayers are completely different.

The quality of extruded feed is closely related to every production link and the equipment selected. If you want to get high-quality extruded feed, you can contact us immediately to get more detailed information.

Can the floating fish feed production line only be used to produce a single floating fish feed pellet?

No. From the above cases and customized solution design, we can see that our feed production line is not only used to produce floating fish feed. Because our entire feed production line is modular in design, each work section can be increased or decreased. Therefore, if there is a demand for the production of shrimp feed, poultry feed, livestock feed, etc., we will take all the customer’s production needs into consideration when designing the feed production plan, and then customize a compound feed production line that can produce a variety of feed types.

For example, 1 ton per hour fish and shrimp feed production line, 2-3 tons per hour floating and sinking fish feed production line, 5 tons per hour floating and poultry feed production line……