Floating Fish

Feed Machine

High Quality Floating Fish Feed Machine

Customized Floating Fish Feed Production Solutions

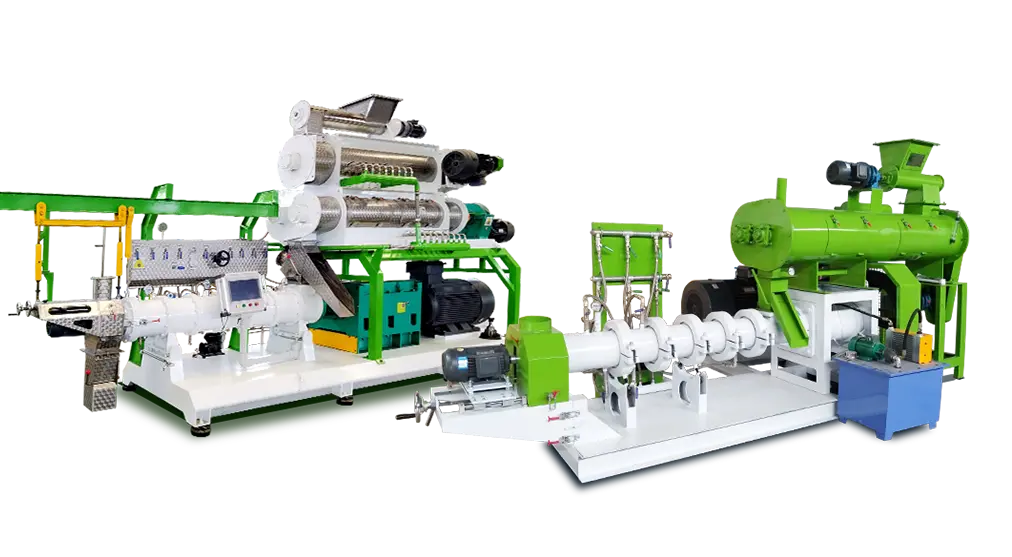

Floating Fish Feed Machine

Single Screw Extruder Machine

RICHI Floating fish feed machine can be widely used to produce high-end aquatic feed pellets that meet the growth needs of a variety of fish. Depending on the raw materials, capacity, investment requirements, etc., you can choose to use twin screw extruder machine or a single screw extruder machine.

Twin Screw Extruder Machine

The raw materials are formed into expanded aquatic feed pellet in the twin-screw extruder through the modulation action of the modulator and the extrusion action of the screw.

As professional floating fish feed machine manufacturer, RICHI can provide you with reliable floating fish feed machine to meet the feeding needs of aquaculture farms and the production needs of feed mill.

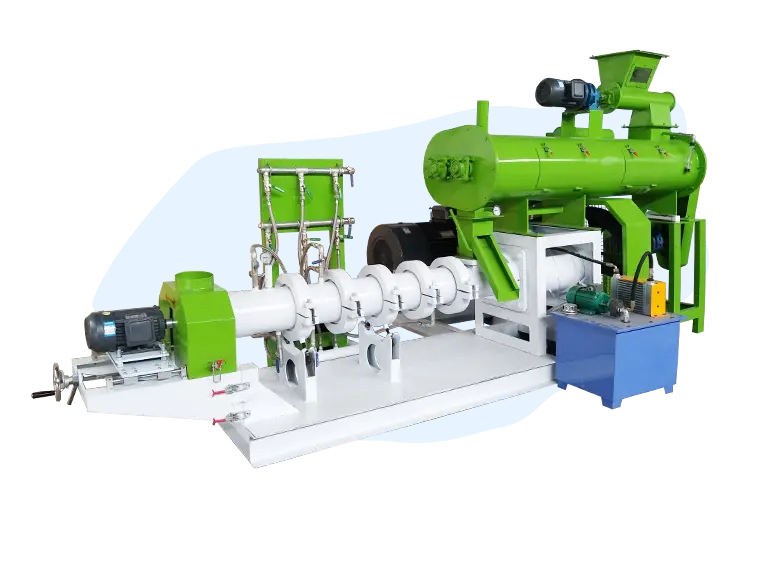

Single screw extruder machine

— Richi Machinery —

RICHI single screw extruder machine can be used to produce high-grade aquatic feed and pet food. It is easy to operate and is currently widely used in small and medium-sized feed processing plants and aquaculture plants.

Single screw extruder machine price: $2,000-$60,000

PLC System

The PLC system is used to accurately control the feeding amount and steam input to improve accuracy.

Screw

Using new materials and the latest processing technology to process the screw to increase the service life of the screw.

Energy Utilization

Make full use of steam to reduce the consumption of electricity and the wear of accessories in the production process, saving processing costs.

Various feed types

It can be used to process a variety of floating and sinking aquatic feeds, as well as the production of suckling pig feed and pet food.

Single screw extruder machine parameters

| Model | Capacity | Machine Power | Feeding Power | Dia. of Screw | Cutting Power |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

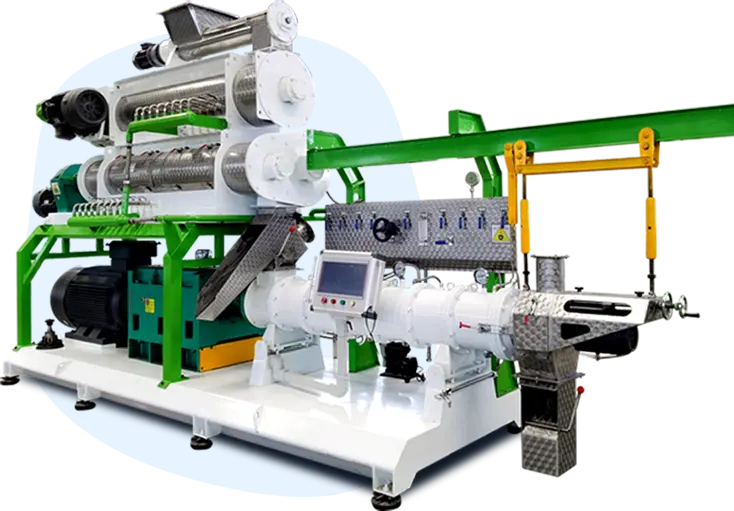

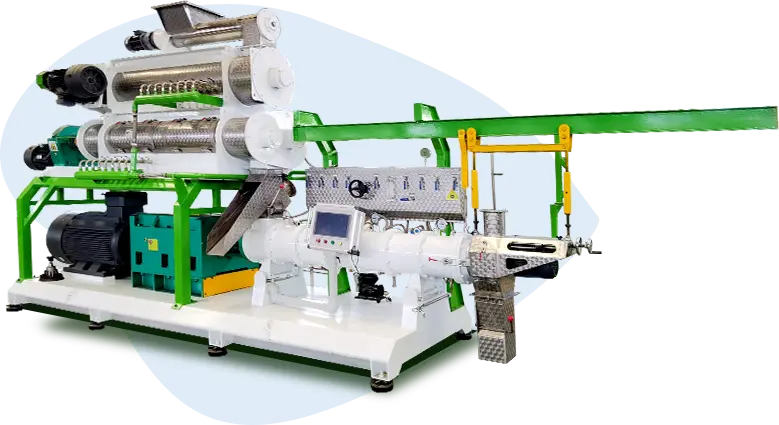

Twin screw extruder machine

— Richi Machinery —

RICHI twin screw extruder machine can be used to produce high-grade floating and sinking aquatic feeds, especially for materials with high oil content and high moisture content, to achieve the purpose of efficient expansion.

Twin screw extruder machine price: $2,000-$100,000

Features of twin screw extruder machine:

feeding system

The feeding system uses a uniquely designed silo to prevent agglomeration and sedimentation.

SKF bearings

The bearings in the transmission box are made of SKF bearings to ensure long-term stable operation.

Extrusion system

The extrusion chamber is equipped with wear-resistant alloy screw and bimetallic expansion chamber sleeve to reduce wear and ensure long-term stable operation of the equipment.

Accessories

All accessories are made of international advanced standards, which effectively improves the running stability of the equipment and effectively controls the noise.

Steam Heating

Using steam heating instead of mechanical energy to generate heat, reduce electricity consumption per ton of material and increase production capacity.

Siemens motor

The main motor is equipped with Siemens motor to ensure the quality of the entire equipment.

Twin screw extruder machine parameters

| Model | Main Power(kw) | Dia. of Screw(mm) | Capacity(t/h) | Matching feeder model-power | Matching differential conditioner model-power |

| SPHS120*2 | 75 | 120 | 1~2 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS120*2 (6.6*1.6*4M 6T) | 90 | 120 | 3~4 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS150*2 | 160 | 150 | 4~5 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS 150*2 (8*2*4.3M 8T ) | 200 | 150 | 6~7 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS185*2 | 315 | 185 | 8~10 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

| SPHS185*2 | 355 | 185 | 10~12 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

Richi Machinery

How does the floating fish feed machine work?

Floating fish feed extruder machine is mainly composed of feeding system, raw material conditioning system and pellet extrusion system.

The material enters the modulator through the variable frequency screw feeder, and is gelatinized and matured by the high temperature, high humidity and high pressure in the modulator, and can also achieve the purpose of sterilization. After the material is modulated to a certain temperature and moisture in the modulator, it enters the extrusion system, is extruded, sheared and kneaded under the action of the screw, and finally is extruded from the die and cut into qualified pellets by the cutter.

Application of Floating Fish Feed Machine

— Richi Machinery —

According to market demand and feed formula, our floating fish feed machine can be used to produce different kinds of fish feed, such as tilapia feed, trout feed, sturgeon feed, catfish feed, salmon feed, ornamental fish feed, etc.

It can meet the feeding needs of medium and large aquaculture farms, as well as the production needs of various aquatic feed pellet mill.

Complete floating fish feed prodiction process

— Richi Machinery —

In addition to floating fish feed extruder machine, feed mills, medium or large-scale aquaculture plants are usually equipped with a complete aqua feed production line to produce aqua feed, which can not only get high-quality aqua feed, but also improve work efficiency, so that the feed mill can achieve maximum benefits.

As professional floating fish feed machine manufacturer, RICHI has designed turnkey floating fish feed production lines for thousands of customers. We can provide you with customized floating fish feed production line solutions according to the specific needs of each customer.

Among them, the process flow of the standard floating fish feed production line is: receiving and processing of raw materials – first crushing and first mixing – second crushing – second mixing – extrusion – drying – spraying – cooling – packing. (Not every feed production project needs to be equipped with all of the following sections. All of our sections are modular in design and can be added or reduced according to your specific needs.)

The process flow of a standard shrimp feed production line:

Receiving and handling of raw materials

Equipped with a reasonable raw material receiving and storage system

First crushing and first mixing

Coarse crushing of raw materials and first mixing

Second crushing

The ultra-fine grinder crushes the raw materials to above 80 mesh

Second mixing

Mix the trace elements, premixes, etc. in the feed formula with the crushed bulk feed.

Extrusion

The material is extruded by the fish feed extruder machine to form expanded feed pellets.

Drying

Dry the extruded feed pellets with a moisture content of 18%-20% to a moisture content of 10%-11%

Spraying

Increase the oil content of feed pellets by spraying with a drum sprayer or vacuum spraying machine

Cooling

Cool to room temperature in a cooler to increase the hardness of the particles for subsequent processing

Packing

Packed into 10-50 kg bags for easy storage, use or sale

Auxiliary Display

— Richi Machinery —

In addition to the single screw extruder machine or twin screw extruder machine, the entire floating fish feed production line may also use grinders, ultrafine grinders, mixers, coolers, belt dryer, spraying equipment, packing equipment and other related equipment in the feed production process.

As a deliverer of turnkey feed production projects, RICHI can provide you with a full range of related equipment required for fish feed production.

Hammer Mill

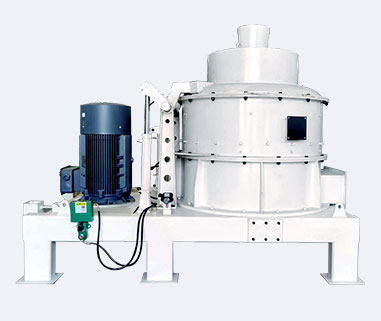

Ultrafine Grinder

Feed Mixer

Feed Extruder

Feed Cooler

Spraying Equipment

Belt Dryer

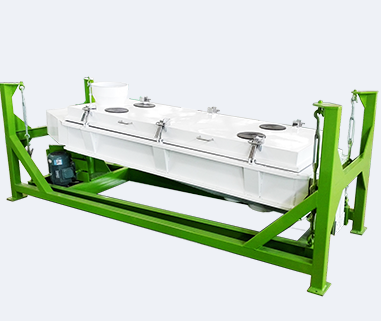

Rotary Screener

Project of Fish Feed Production

— Richi Machinery —

Since its establishment, RICHI has won the favor of many customers with its excellent product quality and outstanding solution design. The floating fish feed machine produced by RICHI is exported to Europe, America, Central Asia, Africa and other countries and regions.

At present, the feed production projects and pellet production projects built by RICHI are spread across more than 120 countries and regions around the world, covering various production lines such as livestock and poultry feed with an hourly capacity of 1-60 tons, high-end aquatic extruded feed, etc.

1-1.2 t/h floating fish feed production line in Indonesia

Feed type: Floating Aquafeed

Major equipment:

Hammer mill SFSP66*80,Mixer 2m3/p,Single screw extruder,Box-type Circumfluent Dryer,Spraying machine,Cooler,Rotary screeter,packing machine30E,Square Plansifter,feed pellet machine,Feed Cooler,Packing machine,Steam boiler

Features of floating fish feed production line:

The entire floating fish feed production line is relatively compact and not very high. Due to the relatively small capacity and taking into consideration the specific circumstances of the customer, we did not equip him with an automatic batching system and chose manual feeding. However, in the packing section, the customer actively requested the use of an automatic packing system. The investment in the entire floating fish feed production line is not large.

5 t/h floating fish feed plant in Russia

Feed type: Mainly produces floating fish feed

Major equipment:

Hammer mill SFSP66*60,Mixer 500kg/p,Ultrafine Grinder SWFL130E,Twin screw extruder SPHS150*2,Box-type Circumfluent Dryer SKGD2000-5ZP,Spraying machine,Cooler,Square Plansifter, Packing Machine

Features of floating fish feed plant:

Since the raw materials used by customers contain high fat content, a twin-screw extruder machine is selected to better process these high fat content raw materials.

The use of a vacuum sprayer allows the grease to be sprayed into the interior of the extruded feed, increasing the grease content and the uniformity of the grease spraying.

3-4 t/h fish feed production line in Vietnam

Feed type: Floating fish feed, sinking fish feed, shrimp feed

Major equipment:

MHammer mill,Mixer,Twin screw extruder,Box-type circumfluent Dryer,Spraying machine,Cooler,Packing machine

Features of fish feed production line:

By changing the starch content in the formula and replacing the screw in the extruder, the feed factory can use the feed extruder machine to produce floating fish feed as well as sinking fish feed and shrimp feed.

The use of a vacuum sprayer allows the oil to be sprayed into the interior of the extruded feed, increasing the oil content and the uniformity of the oil spraying.

1-1.5 t/h floating fish & 5-7 t/h livestock feed production line in India

Feed type: Floating fish feed, poultry and livestock feed

Major equipment:

Hammer mill SFSP66*80,4 sets 20 Ton Silo,Mixer 2m3/p,Single screw extruder,Feed pellet machine SZLH350,Box-type Circumfluent Dryer,Spraying machine,Cooler,Rotary screeter,Packing machine

Features of feed production line:

The feed mill is also equipped with fish feed extruder machine and feed pelletizer, which can be used to produce floating fish feed in the peak season and to produce poultry or livestock feed in the off-season. The feed mill is utilized to the maximum extent to improve its efficiency.

Floating fish feed machine can be customized design

In addition to the commonly used floating fish feed machine, RICHI Machinery can also customize floating fish feed machine according to the specific needs of customers, including special production requirements, local voltage, type of modulator (ordinary modulator, differential modulator, quality control device), etc.

With customer-centric design, we customize floating fish feed machine to meet the needs of each customer.

Frequently asked questions

Why use a superfine grinder for the second grinding?

Since aquatic animals have low food intake, short digestive tracts, and poor digestive capacity, the raw materials used to produce aquatic feed require a very low pellet size to increase the digestibility of the feed by aquatic animals. Therefore, using an ultra-fine grinder to grind the raw materials for the second time can increase the grinding fineness of the raw materials and obtain higher quality aquatic feed.

The ultrafine grinders we produce are widely used in the crushing of various aquatic feed raw materials and can well meet the production needs of aquatic feed.

Why can’t grease be added directly into the mixer, but must be sprayed using spraying Equipment?

In principle, oils and fats can be added to the mixer and mixed with the raw materials. However, the fish feed extruder machine has strict requirements on the fat content in the raw materials during expansion and extrusion. When using a single screw extruder machine to produce aquatic feed, it is recommended that the fat content in the raw materials should not exceed 8%; when using twin screw extruder machine to produce aquatic feed, it is recommended that the fat content in the raw materials should not exceed 15%.

Therefore, in order for the fish feed extruder machine to work properly, the oil cannot be added directly into the mixer, but needs to be sprayed onto the surface and inside of the extruded feed using a sprayer after the extrusion is completed.

Is it necessary to have a boiler to produce extruded fish feed?

The boiler is not a must. The main function of the boiler is to provide hot steam to the modulator of the fish feed extruder machine to improve the maturation of the material.

However, fish feed extruder machine are divided into dry feed extruder machine and wet feed extruder machine. There is no regulator on the dry extruder, so there is no need to equip it with a steam boiler to provide hot steam.

If the feed formula contains some heat-sensitive raw materials, they will be destroyed by high temperature during feed extrusion. What should we do in this case?

The temperature in the fish feed extruder machine is relatively high, for example, for a twin-screw extruder machine, it can even reach 200 degrees. High temperature can improve the maturity and sterilization of materials, but at the same time, if the feed formula contains heat-sensitive raw materials, such a high temperature will cause certain damage to the heat-sensitive raw materials.

In this case, the heat-sensitive raw materials can be added directly to the oil to be sprayed without passing through the fish feed extruder machine, and then sprayed onto the surface and inside of the feed through the spraying machine.