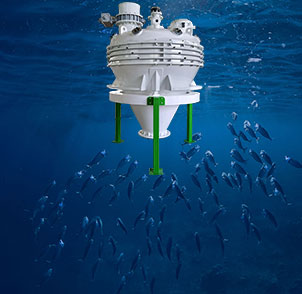

Customized Turnkey Fish Feed Production Project

FIsh feed production line

We can provide fish feed production lines with the output of 1-50 tons per hour, and can also provide the most advanced fish feed making machine for fish feed pellet mill.

RICHI MACHINERY

fish feed production line manufacturer

As the professional fish feed production line manufacturer, our fish feed production line solutions are designed to improve the production efficiency of fish feed mill, reduce production costs, and ensure that fish feed pellet mill produce high-end aquatic feed.

- The output of fish feed production line we can provide: 0.5-50 ton per hour

- Applications of fish feed production line: aquatic feed plant, aquaculture factory, pet food factory, animal feed production plant

- Types of feed processed by the fish feed production line: It can produce fish feeds such as trout, herring, salmon, tilapia, salmon, ornamental fish, etc. It can also produce shrimp feed, crab feed, pet food, poultry and livestock feed.

- Processable raw materials: rice bran, bean cake, silkworm pupa powder, bran, fish meal, barley meal, corn meal, vitamins, bone meal, etc.

RICHI MACHINERY

Application of fish feed production line

In response to the growth and development needs of different types of fish, we can provide single-type fish feed production lines, such as trout feed production lines, herring feed production lines, salmon feed production lines, salmon feed production lines, ornamental fish feed production lines, etc.

At the same time, in order to maximize the benefits of fish feed pellet mill, we can also provide compound feed production lines for fish feed mill, such as fish and shrimp feed production lines, fish and pet feed production lines, fish and poultry feed production lines, etc. The advantage of compound feed production lines is that you only need to add appropriate feed making machine to the original fish feed production line to meet the production needs of various feeds, with small investment and high returns.

The following are several common fish feed production lines:

Trout feed production line

From the design of trout feed production solutions to the production, manufacture and installation of trout feed making machine, the complete trout feed production solution can help you quickly start your fish feed production business.

Tilapia feed production line

According to the different production stages of tilapia, fish feed pellets of different sizes can be designed to be produced on the same fish feed production line to meet the feeding needs of tilapia.

Sturgeon feed production line

At RICHI, you can get a full set of sturgeon feed pellet machine and sturgeon feed production turnkey projects with guaranteed quality and worry-free after-sales.

Eel feed production line

According to your actual production needs, RICHI can transform your eel feed production ideas into standardized design plans and put them into actual project production.

Seabass feed production line

We provides high-quality services to global fish feed manufacturers with innovative sea bass feed production line designs and a full set of high-quality sea bass feed pellet machine.

Aquatic feed production line

A complete set of aquatic feed pellet machine can produce high-end floating feed, slow sinking feed, sinking feed, etc. according to the feeding and growth and development needs of different types of aquatic organisms.

Fish and shrimp feed production line

According to different feed formulas, fish feed, shrimp feed and crab feed can be produced on one production line at the same time, which can meet the needs of feed factories in aquatic feed production to the greatest extent.

Fish and pet food production lines

The pet market is developing rapidly. Our feed production solutions can not only meet the production of high-end fish feed, but also produce pet food that is deeply loved by pets according to market demand.

RICHI MACHINERY

The process of fish feed production

How to produce fish feed? What is the complete process of fish feed production? What are the steps involved in producing fish feed? These are the questions that fish feed producers usually have when investing or starting the fish feed production business.

Therefore, we will customize fish feed production line solutions for you according to your specific needs. Due to the differences in the types of raw materials, the area and height of the fish feed plant, investment requirements, etc., each fish feed production line solution will be very different.

The conventional fish feed production process includes: receiving and cleaning raw materials – first crushing and first mixing – second crushing and second mixing – extrusion or granulation – drying – spraying – cooling – screening and packing

The fish feed production process is as follows:

Receipt Of Raw Materials

The receipt of raw materials is the initial stage of fish feed production. According to production needs and the amount of raw materials used in the feed formula, the storage of raw materials can be completed using a silo receiving system.

First crushing and first mixing

The raw materials are crushed into small particles to reduce the particle size of the raw materials, which is convenient for subsequent extrusion, granulation, etc. The crushed raw materials are roughly mixed according to the feed formula.

Second crushing and second mixing

In order to meet the growth needs of fish, fish feed production usually involves a second crushing to improve the quality of fish feed pellets. The materials are then fully mixed according to the feed formula.

Extrusion or granulation

The mixed materials are extruded or pelletized to form high-end fish feed pellets. In this process, you can choose to use fish feed extruder machine or fish feed pelletizer.

drying

Drying is to reduce the moisture content in the feed pellets. The moisture content of the feed pellets after drying is about 13%, which can increase the storage time of the feed pellets.

Spraying

Oil, vitamins, spices and other materials are sprayed onto the surface and inside of feed particles through spraying equipment to improve the nutritional content and palatability of feed particles.

cooling

The temperature of the feed pellets after the above treatment is relatively high. In order to quickly cool them to room temperature or slightly below room temperature, cooling equipment is required to cool them down.

Screening

Screening is to improve the quality of fish feed pellets. Use screening equipment to screen out qualified feed pellets from the feed pellets, and unqualified ones need to be returned for reprocessing.

Packing

The qualified fish feed pellets screened out are packed into bagged feed pellets through weighing, bagging, sealing, palletizing and other processes. Bulk feed pellets can also be directly transported by truck.

RICHI MACHINERY

finished fish feed

The fish feed production line we design and the fish feed making machine we provide produce feed pellets that can meet the growth and development needs of a variety of fish and aquatic organisms.

Tilapia

Trout

Eel

Catfish

Ornamental fish

Sturgeon

Salmon

Sturgeon

Cichlids

Seabass

Catfish

Litopenaeus vannamei

Penaeus monodon

Litopenaeus setiferus

Macrobrachium rosenbergii

Farfantepenaeus aztecus

Cat

Dog

RICHI MACHINERY

Fish feed processing technology

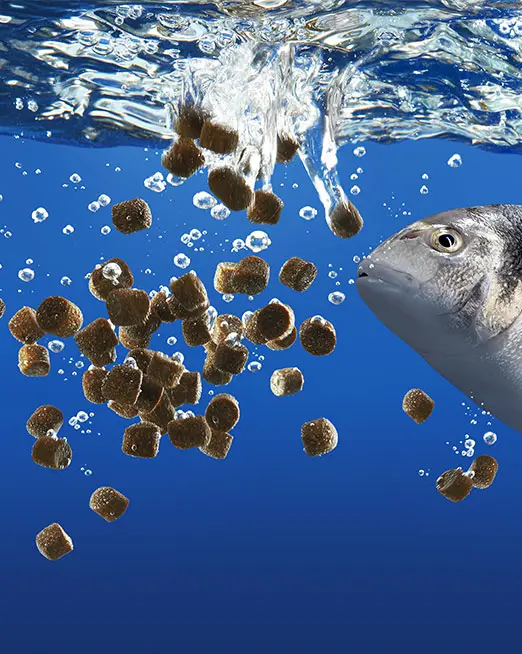

Extruded fish feed or pelletized fish feed? These are two common types of fish feed, which are made from two different production processes: floating fish feed and pelletized fish feed pellet.

The main difference between the processing technology of floating fish feed and sinking fish feed pellet lies in the different equipment used in the pelletizing or extrusion process.

The main equipment used in the floating fish feed processing technology is the fish feed extruder machine, which can be the twin-screw extruder machine or a single-screw extruder machine.

The main equipment used in the processing of sinking fish feed pellet is the fish feed pelletizer with a multi-layer modulator, but fish feed extruder machine can also be used to process sinking fish feed pellets, which is also popular in the fish feed production industry.

In addition, fish feed extruder machines can also be used to process slow sinking fish feed pellets to meet the specific feeding needs of some aquaculture farms.

Floating fish feed

The high-fat, high-water content fish feed pellets produced by the extrusion process can float on the water surface for a long time, which can meet the growth and development needs of surface-feeding fish such as trout, catfish, and eels.

Slow sinking fish feed

The fish feed produced by the extrusion process can sink slowly in the water. After feeding, it will not sink to the bottom of the water quickly, so that the fish can have more time to eat, reducing feed waste and water pollution.

Sinking fish feed pellet

A kind of fish feed pellets produced by extrusion or granulation process that can quickly sink to the bottom of the water after feeding, mainly used to meet the growth and development needs of bottom-feeding fish.

RICHI MACHINERY

Fish feed production lines with different outputs

We provide multiple design solutions for fish feed pellet mills with different outputs to meet the production needs of all fish feed manufacturers.

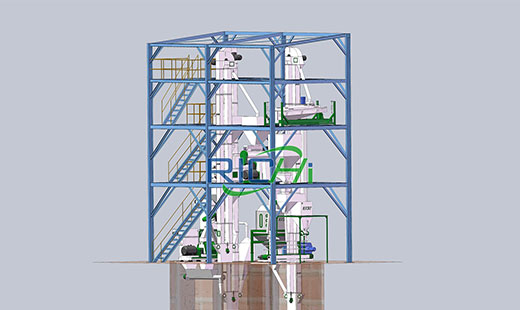

1-2 ton/h fish feed production line

Taking into account the plant area, plant height, investment budget, etc., the fish feed production line solution designed for large-scale aquaculture farms and fish feed production plants is favored by many fish feed manufacturers.

3-4 ton/h fish feed pellet line

RICHI has been committed to building 3-5 tons per hour fish feed pellet mills for customers in need. It has accumulated a lot of mature experience in fish feed factory construction and can meet the various needs of 3-5 tons per hour fish feed producers in the production process.

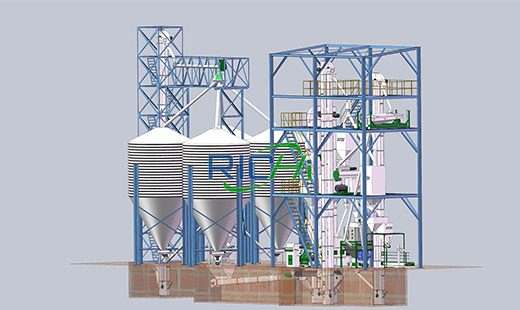

5-7 ton/h fish feed pellet plant

5-7 tons per hour automated fish production solutions are available, including the cooperation of multiple automated systems such as automatic batching and automatic packing, which can effectively improve the production efficiency of the fish feed plant and maximize its benefits.

8-10 ton/h fish feed mill

The customized fish feed production line solution of 8-10 tons per hour can fully consider your actual production needs; the best fish feed factory production equipment can ensure the efficient and orderly operation of the entire fish feed factory.

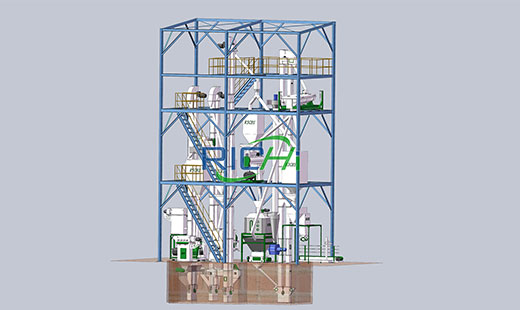

10-12 ton/h fish feed pellet mill

RICHI optimizes the fish feed processing technology, improves fish feed making machine, and provides brand-new fish feed production line solutions for fish feed manufacturers.

12-15 ton/h fish feed factory

The 12-15 tons per hour high-end fish feed production line solution can help you improve the quality of fish feed pellets, allowing you to quickly occupy the fish feed market share and maximize profits in the industry.

15-17 ton/h Fish feed production solutions

Based on the innovative, high-standard and systematic fish feed production line design process and based on your actual needs, we can customize a 15-17 tons per hour modern fish feed production line solution for you.

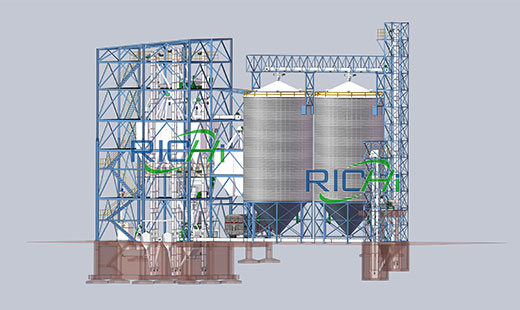

18-20 ton/h Fish feed mill plant

The 18-20 tons per hour turnkey fish feed production line project includes the planning and design of the feed factory, the design of the feed production line, the production and installation of fish feed making machine, allowing you to start your fish feed production business with peace of mind.

20-25 ton/h aqu feed mill plant

Large fish feed production line, can be used in large fish feed production plants, aquatic feed production plants, large aquaculture enterprises and investors interested in fish feed production.

RICHI MACHINERY

fish feed production line price

How much does it cost to build the fish feed factory? To know the price of the fish feed pellet mill, you must first figure out what investments are needed to build the fish feed factory.

The cost of building the fish feed pellet mill mainly includes raw material cost, fish feed making machine investment, labor cost, factory building cost, transportation cost, management cost, etc. Therefore, if you want to clearly understand the investment cost of a fish feed production plant, you need to consider these influencing factors comprehensively.

The following is the investment in fish feed making machine when building the fish feed pellet mill, which is the most important part of the fish feed factory.

As for the cost of raw materials, plant construction cost, etc., we need to calculate according to your needs, and then combine with the investment in fish feed pellet machine to calculate the comprehensive cost of building the fish feed mill.

| Fish Feed production line output | fish feed production line price (USD) |

| 300-500 kg/h fish feed production line | 30000-80000 |

| 500-600 kg/h fish feed pellet line | 50000-100000 |

| 800-1000 kg/h fish feed pellet plant | 70000-170000 |

| 1-2 ton/h fish feed line | 120000-560000 |

| 3-4 ton/h fish feed production line | 220000-650000 |

| 5-6 ton/h fish feed pellet line | 450000-900000 |

| 8-10 ton/h fish feed pellet mill | 550000-1200000 |

| 10-12 ton/h fish feed production line | 670000-1800000 |

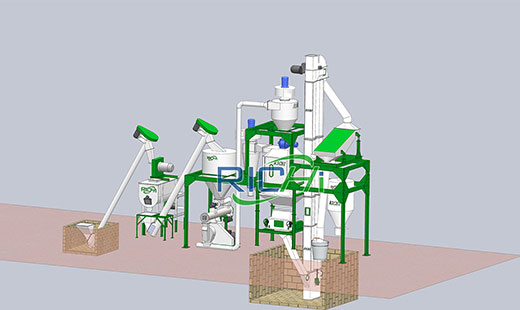

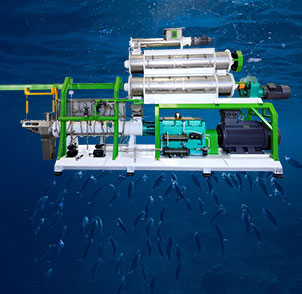

Fish feed production line related equipment

The investment in fish feed production line is also the investment in fish feed making machine. While providing customized fish feed production solutions, RICHI also provides you with the full set of fish feed production equipment used in the fish feed production process, such as fish feed extruders, fish feed pelletizers, fish feed pellet drying equipment, fish feed crushing equipment, fish feed screening equipment, fish feed pellet packing equipment, etc.

The main equipment used in the fish feed production line are as follows:

Twin scren w extruder

Dry Type fish feed extruder

Wet Type Fish Feed Extruder

Fish Feed Pelletizer

Hammer Mill

Ultrafine Grinder

Feed Mixer

Belt Dryer

Spraying Machine

Pellet Packing Machine

Fish feed production projects

— Richi Machinery —

RICHI has currently built more than 200 feed pellet production projects in more than 130 countries and regions around the world, including floating fish feed production projects, sinking fish feed production projects, poultry feed production projects, chicken feed production projects, cattle feed production projects, shrimp feed production projects, etc.

No matter what kind of feed pellets you want to produce? No matter what your raw materials are? No matter which country or region you are located in, RICHI can provide you with the appropriate feed pellet production solutions with rich practical experience and open the door to the field of feed pellet production with you.

5 t/h fish feed production line in Russia

Feed types: Mainly fish feed

Equipments: 5 ton/h twin-screw extruder machine, crusher, ultrafine grinder, belt dryer, cooling equipment, vacuum spraying equipment, fully automatic packing system, fully automatic batching system

Project Introduction:

The project is located in Russia and mainly produces fish feed pellets. It is an investment project. For customers, this is a relatively large feed production project. Therefore, customers are very cautious when choosing partners. They came to our factory for a field visit and conducted face-to-face communication before determining the cooperation plan.

Relying on this fish feed production line, customers can use soybean meal, bran, fish meal, rice bran and other raw materials to produce fish feed with pellet size between 0.5-12mm. At present, the production line has been fully installed and put into operation.

1-2 t/h Fish feed and animal feed production lines in Uzbekistan

Feed types: Floating fish feed, chicken feed, cattle feed, sheep feed

Equipments: Hammer mill, ultrafine grinder, mixer, feed granulator, feed extruder machine, dryer, cooler, packing machine

Project Introduction:

The feed production project is located in Uzbekistan and is mainly used to produce floating fish feed and animal feed pellet such as chickens, cattle and sheep.

According to the local market conditions, the customer found that the local demand for fish feed was growing and the quality requirements for fish feed were also increasing. He believed that fish feed production had a relatively large market and good prospects, so he decided to invest in this area.

500kg/h fish feed production line in Cote d’Ivoire

Feed types: Floating fish feed pellets

Equipments: Fish feed extruder, mixer, drying equipment, drum sprayer, cooler, packing equipment

Project Introduction:

Project Introduction: The customer has its own farm in Cote d’Ivoire and has high requirements for the quality of fish feed pellets, so it decided to introduce a 500kg/h high-end aquatic feed production line to meet the breeding needs of the farm.

Since the customer has many years of experience in purchasing aquatic feed pellets, he attaches great importance to the quality of feed making machine.

1-2 t/h fish feed pellet line in Indonesia

Feed types: Mainly used for the production of floating fish feed

Equipments: 2 t/h twin screw extruder machine, crusher, mixer, drying equipment, vacuum sprayer, packing equipment, conveying equipment, dust removal equipment

Project Introduction:

This fish feed pellet production line is located in Indonesia and is mainly used to produce floating fish feed. The customer combined the local market conditions, saw that the local demand for fish feed was increasing, and the quality requirements for fish feed were getting higher and higher. He believed that fish feed had a relatively large market and good prospects, so he decided to invest in this field.

The customer came directly to our factory to discuss the construction of a fish feed production plant with us, and finally reached a cooperation with us.

2 t/h aquatic feed production line in Iran

Feed types: Floating fish feed pellets, shrimp feed pellets

Equipments: 2 t/h twin screw extruder machine, feed granulator with three-layer modulator, crusher, ultrafine grinder, high square sieve, belt dryer, grease adding system, vacuum sprayer, packing equipment, etc

Project Introduction:

This feed pellet production project is located in Iran. The customer built this fish feed pellet mill to produce fish feed for its own aquaculture farms and also sell part of the fish feed to make a profit.

After the customer contacted us, he quickly determined that we were a professional aquatic feed pellet machine manufacturer, so he signed a contract with us after finalizing the design plan.

3-5 t/h fish feed production line in Algeria

Feed types: Floating fish feed, sinking fish feed

Equipments: Hammer mill SFSP 66*60, silo, feed mixer, ultrafine grinding equipment SWFL130E, square sieve, feed pellet machine, feed extruder, feed cooler, packing machine, steam boiler

Project Introduction:

This feed production line is mainly used to produce fish feed. It is equipped with feed pelletizer and feed extruder in the pelletizing and extrusion sections. Therefore, it can produce floating fish feed and sinking fish feed according to market demand and feed formula, thus improving the efficiency of the fish feed pellet mill.

In addition, if there is a demand for pet feed production or poultry and livestock feed production in the subsequent production process, it can also be produced on this feed production line.

RICHI MACHINERY

Fish feed production line video

Indonesia’s demand for aquatic feed mainly includes two aspects: fish feed and shrimp feed. According to the output of Indonesia’s aquatic products, Indonesia’s demand for fish feed mainly includes tilapia feed, catfish feed, carp feed, and milkfish feed; the demand for shrimp feed mainly includes shrimp feed.

As world-renowned fish feed making machine manufacturer, RICHI can provide high-quality fish feed making machine for Indonesian aquatic feed producers based on the local breeding status and future development trends in Indonesia.

5 t/h fish feed production line in Russia

1-2 t/h Fish feed and animal feed production lines in Uzbekistan

500kg/h fish feed production line in Cote d’Ivoire

2 t/h aquatic feed production line in Iran

Why invest in fish feed production?

Fish feed production has attracted more and more attention as a business plan. Many investors are interested in the development potential and profit space of fish feed production, especially in the context of the rapid development of global aquaculture.

Aquaculture industry growing rapidly

As wild catch resources decrease, aquaculture becomes the main way to supply fish. The global aquaculture industry grows by 5%-7% annually, and the rapid growth of aquaculture drives the demand for aquatic feed.

High-end aquatic feed demand is strong

Traditional fish feeds have serious homogeneity, low conversion rate, water pollution and other problems. Aquaculture farmers are looking for better aquatic feeds, and aquatic feeds with high protein and high fat content have become the first choice.

Improved efficiency of the breeding industry

High-end aquatic feed can increase the growth rate of fish and reduce feed waste, thereby reducing breeding costs, improving fish survival rate, increasing breeding income and improving breeding efficiency.

Complete industrial chain

At present, fish feed production has formed a complete industrial chain. Both the raw material supply and market awareness are relatively stable, so high-end aquatic feed can stand out in the market.

High return on investment

The market demand for aquatic feed is stable, and the profit margin is much higher than that of ordinary agricultural products. The gross profit margin of high-end aquatic feed can reach 30%-50%, which is a very considerable profit margin.

Strong scalability

Initial investment can produce single feed, such as trout feed, tilapia feed, and then gradually expand to special fish feed, ornamental fish feed, shrimp feed to increase market share.

RICHI MACHINERY

How to Build a Fish Feed Pellet Mill?

Building the fish feed factory usually starts from the following aspects: market research, fish feed pellet mill site selection and construction, fish feed making machine procurement, raw material procurement, quality control, and personnel recruitment.

1. Market Research

Understand the development trends of the local and surrounding aquatic product markets and determine target markets and product positioning.

2. Fish feed factory site selection and construction

The preferred location for a feed mill is close to the raw material production area, close to the target market, and has convenient transportation.

3. Procurement of fish feed making machine

Determine the fish feed production process and select appropriate fish feed making machine according to the production scale and product types of the fish feed factory.

4. Raw material procurement

Establish a stable raw material supply channel, select high-quality feed raw materials, sign contracts with suppliers, and ensure the quality and supply stability of raw materials.

5. Quality Control

Establish a sound quality management system, equip with necessary testing equipment and personnel, and conduct strict quality inspections on raw materials and finished products.

Frequently asked questions

How to Start the Fish Feed Production Business?

Starting the fish feed production business requires preparation and planning from many aspects, such as:

- Preliminary research and planning of fish feed market

- Site selection of fish feed factory and construction or rental of fish feed plant

- Raw material procurement and supplier management

- Production management and quality control of fish feed during production

- Recruitment and training of fish feed production workshop personnel

- Marketing and Customer Service

Each of these sections contains a lot of content. Although the fish feed production business may seem troublesome, if you find the right partner, everything will become organized and simple, allowing you to quickly start a fish feed production business in a limited time.

what equipment is suitable for making fish feed

There are many kinds of equipment for making fish feed. Different types of fish feed production require different equipment, and different outputs of fish feed production also require different equipment. Generally speaking, the production of fish feed mainly requires: raw material crushing equipment, mixing equipment, extrusion equipment, granulation equipment, drying equipment, spraying equipment, cooling equipment, packaging equipment, etc.

Through reasonable configuration, these equipments can efficiently produce high-quality fish feed to meet market demand.

How can we produce high-quality extruded feed?

In order to obtain high-quality extruded floating feed, every link in feed production is important, and there are several key points to pay attention to:

- First of all, the raw materials should be ground finely. The finer the raw materials are ground, the easier it is to mix fully with steam in the modulator, the easier it is to extrude the raw materials in the extrusion chamber, and the easier it is to obtain puffed feed with a smooth surface and uniform color.

- Secondly, a reasonable formula is the key factor in producing high-quality extruded feed, especially the starch content in the raw materials, because the starch content is the key factor that determines the buoyancy and sinking properties of extruded feed.

- In addition, whether to choose spraying equipment and the choice of sprayer. Spraying can significantly increase the oil content of extruded feed particles. Different spraying equipment brings different effects. For example, the spraying effects brought by drum sprayer and vacuum sprayer are completely different.

The quality of extruded feed is closely related to each production link and the selected equipment. If you want to get high-quality extruded feed, you can contact us immediately for more detailed information.

Do you provide shipping and installation services?

We provide shipping and installation services to all our customers, and we can continue to provide our customers with peace of mind after-sales service.

ABOUT RICHI MACHINERY

RICHI was founded in 1995. Over the past 30 years, it has served Europe, America, Africa, the Middle East, Asia and other regions. The feed making machine and pellet production equipment it produces are exported to many countries and regions in the world.

As the professional feed making machinery manufacturer and pellet production equipment manufacturer, RICHI focuses on the design and manufacture of 1-100 tons/hour feed production projects and 1-50 tons/hour wood pellet production projects, and is committed to creating high-quality feed and pellet production projects for global customers.