RICHI in world

Fish Feed Pellet Machine in Philippines

RICHI MACHINERY

Overview of the Philippine Aquaculture Market

The Philippines ranks sixth in the world in terms of aquaculture production and is one of the leading aquaculture exporters in Asia.

The Philippines is an archipelago consisting of 7,641 islands. It is bordered by the Pacific Ocean to the east, the South China Sea to the west, and major water bodies such as the Luzon Strait and the Celebes Sea to the north. The total length of the coastline is 36,289 kilometers. The superior natural conditions provide a natural breeding environment for the development of local aquaculture.

The Philippines strongly supports the development of aquaculture. The fishery sector plays an important economic role in the local area and also provides many jobs for Filipino residents.

With the rapid development of local aquaculture, the output and quality of aquatic feed pellet in the Philippines are also constantly improving. In order to meet the needs of aquaculture, local feed mills have introduced advanced feed pellet machine to ensure the production of fish feed pellet.

RICHI MACHINERY

RICHI can provide high-quality fish feed pellet machine

The main aquaculture species in the Philippines are Milkfish and Shrimps/prawns, in addition to Seaweeds, Tilapias, Molluscs, Crabs and other aquatic creatures.

In order to obtain better quality of aquatic products and higher yields, centralized aquaculture usually uses aquatic feed pellet for feeding, and the quality of aquatic feed pellet directly determines the quality and yield of the fish fed.

As global professional fish feed pellet mchine manufacturer, with professional technical level and rich experience, we can provide fish feed pellet machine with an capacity of 0.5-14 tons per hour for the production of aquatic feed pellet in the Philippines.(We can provide fish feed pellet machine with regular capacity, fish feed pellet machine with special output and feed pellet production equipment for producing special fish feed pellet, so as long as you have plans for fish feed pellet production, you can contact us directly.)

1-5 t/h floating fish feed making machine

Floating fish feed extruder is a special production equipment for producing fish feed. It is suitable for small and medium-sized feed processing plants and aquaculture plants. It can produce feed suitable for the growth and development of salmon, trout and other fish.

1-12 t/h fish food making machine

Twin screw fish feed extruder can be used to process raw materials with high oil and high moisture content, meet the processing needs of a variety of special raw materials, and is suitable for medium and large fish feed mill.

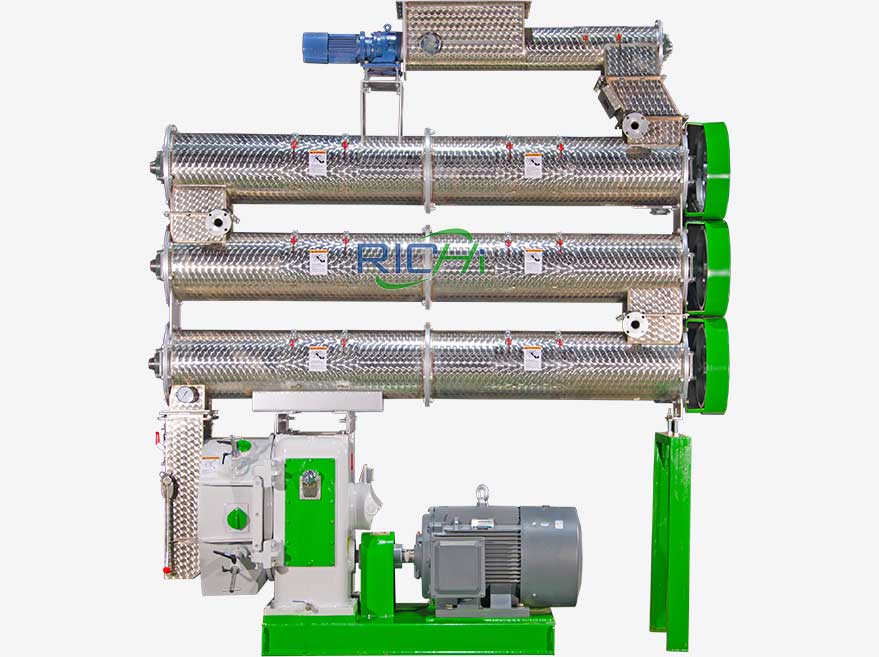

1-10 t/h sinking fish feed pellet machine

The fish feed pellet machine with double-layer modulator can produce high-quality aquatic feed pellets to meet the feeding needs of a variety of fish and is economical and applicable.

Milkfish feed making Machine

RICHI has developed fish feed pellet machine specifically for the production of salmon feed. The raw materials are subjected to high temperature, high pressure and high humidity during the processing process to form extruded aquatic feed with relatively high maturity and gelatinization degree.

Shrimps feed extruder machine

Used to produce various sizes of puffed shrimp feed pellet from 0.6 to 6 mm. The modulator is made of stainless steel, equipped with Siemens motor and SKF bearings, which can ensure the quality of finished shrimp feed pellets.

prawns feed pellet making machine

According to special needs, we can provide customers with shrimp feed pelletizing machines with three-layer modulators to further improve the maturity and gelatinization of materials to meet the production of special shrimp feed.

Fish feed pellet machine is a very important equipment in aquatic feed pellet production. However, in aquatic feed mills or in the process of intensive production of fish feed pellet, in addition to fish feed pellet machine, a variety of auxiliary equipment such as hammer mill, mixers, drying machine, coolers, sprayeing machine, packing equipment, etc. are also needed to form a complete fish feed production line.

Continuous production can produce high-quality fish feed pellet and improve the production efficiency of fish feed pellet. RICHI can provide turnkey fish feed production lines to meet the large-scale production needs of fish feed mills.

If you are interested in fish feed pellet machine or fish feed production line, please contact us directly!

RICHI MACHINERY

RICHI fish feed pellet machine in the Philippines

As dedicated feed pellet production equipment manufacturer, RICHI can provide poultry feed pellet machine, livestock feed production equipment, fish feed pellet machine, shrimp feed pellet production equipment, etc.

At present, RICHI’s feed production equipment and pellet production equipment have been exported to more than 120 countries and regions around the world. At the same time, medium-sized or large-scale feed mills and fish feed mills have been built in many countries, such as a 5-ton per hour fish feed production line in Russia, a 10-ton per hour feed production line in Uzbekistan, and a 20-ton feed production line in Thailand.

As a country with a large demand for feed, many feed mills and breeding plants in the Philippines have purchased fish feed pellet machine, feed production equipment, fish feed mills, etc. from our company.

The following is the detailed information of a 5-ton-per-hour aquatic feed production line we built in the Philippines.

5 t/h aquatic feed pellet machine Introduction

Philippine customer planned to invest in building an aquatic feed production plant. As a very important part of the fish feed mill, the aquatic feed production line was built by us.

This 5 ton per hour fish feed production line adopts advanced technology and equipment, and has the characteristics of high efficiency, intelligence, and safety, which can fully meet the production needs of Philippine customers.

The whole fish feed production line adopts a fully automatic design, and the investment cost is slightly higher, but it is within the acceptable range for customers. The slightly higher investment cost greatly improves the working efficiency of the fish feed production line, reduces labor costs, and the final result is satisfactory to customers.

This fish feed factory is a standard modern feed production project. The entire workshop is dust-free and pollution-free during the production process.

5 t/h fish feed production line process

Our professional engineers designed a variety of solutions based on customer needs. After many communications, we finally determined the following fish feed production plan.

The entire fish feed production line consists of eight sections. The process of fish feed production is: storage system – raw material receiving system – crushing system – batching system – ultrafine crushing system – second mixing system – extrusion and drying system – packing system.

The introduction of each section is as follows:

●

Storage System

According to the raw materials and subsequent production needs of customers, 12 sets of 30-ton conical silos are equipped to meet the storage needs of raw materials.

●

Raw material receiving system

Equipped with pulse dust removal system, cylindrical primary cleaning screen, permanent magnetic cylinder, etc., it can clean impurities in raw materials and ensure the cleanliness of raw materials.

●

Crushing system

For materials that need to be crushed, use a pulverizer for coarse crushing to reduce the particle size difference of the material and improve the working condition of the subsequent ultrafine pulverizer.

●

Batching and mixing systems

Equipped with a rotary distributor and a batching scale, the ingredients are batched by computer according to the feed formula to ensure accuracy, and then the first mixing is carried out.

●

Ultrafine grinding system

Use ultra-fine grinder to grind the material again to above 60 mesh to meet the needs of producing fish feed pellet.

●

Second mixing system

The crushed raw materials and the premixes, additives, oils and fats that need to be added are evenly mixed to form the material to be extruded.

●

Extrusion and drying systems

The mixed materials are made into 1-4 mm fish feed pellets using a twin-screw extruder and then dried in drying machine.

●

Packing system

Use pellet packing scale to package the finished feed pellets into bagged feed for easy storage, transportation and sales.

Some equipments needed for 5 t/h fish feed production line

We provide all the equipment needed for the entire fish feed production line, from the storage system of raw materials to the packaging of finished feed pellets into bags. We have detailed production lists, delivery lists, installation drawings, etc.

The following are the main equipment needed for each section of the fish feed production line. In addition to these equipment, there are also some auxiliary equipment and accessories such as buffer bins, butterfly valves, pneumatic tees, etc. After all the equipment is installed, it constitutes a fish feed production line that can be continuously produced.

| Section | Number | Equipment Name | Model | Quantity |

| Storage System | 1 | Scraper conveyor | TGSS20 | 6 |

| 2 | Conical silo | φ3.67m*3C Volume 46m³ 34T | 12 | |

| 3 | Bucket elevator | TDTG40X23 | 1 | |

| Raw material receiving system | 1 | Fan | 4-72-3.2A | 2 |

| 2 | Pulse dust collector | TBLMa.12A | 2 | |

| 3 | Scraper conveyor | TGSS20 | 2 | |

| 4 | Drum primary screening | SCY63 | 1 | |

| 5 | Permanent magnet cylinder | TCXT20 | 1 | |

| Crushing system | 1 | Impeller Feeder | SWLY20*60a | 1 |

| 2 | Crusher (including shock absorber) | SFSP66*60 | 1 | |

| 3 | Fan | 4-72-5A | 1 | |

| 4 | Pulse dust collector | TBLMa.36A | 1 | |

| 5 | Closed air auger | TLSS25 | 1 | |

| Batching and mixing systems | 1 | Rotary distributor | TFPX8 | 1 |

| 2 | Permanent magnet cylinder | TCXT20 | 1 | |

| 3 | Powder cleaning equipment | SCQZ60*50*100 | 1 | |

| 4 | Ingredients Auger | TWLSS20 | 12 | |

| 5 | 0.5 ton weighing bucket | TCD0.5T | 1 | |

| 6 | Fan | 4-72-2.8A | 1 | |

| 7 | Pulse dust collector | TBLMa.6A | 1 | |

| 8 | 500kg single shaft paddle mixer | SLHJ1A | 1 | |

| Ultrafine grinding system | 1 | Permanent magnet cylinder | TCXT20 | 1 |

| 2 | Anti-arch silo | / | 1 | |

| 3 | Ultrafine pulverizer | SWFL130E | 1 | |

| Second mixing system | 1 | High Plansifter | SFSJ.100X2 | 1 |

| 2 | Ingredients Auger | TWLSS20 | 2 | |

| 3 | 0.5 ton weighing bucket | TCD0.5T | 1 | |

| 4 | Premix hopper | / | 1 | |

| 5 | Stainless steel batching silo | / | 12 | |

| 6 | Stainless steel single shaft paddle mixer | SLHJ1A | 1 | |

| Extrusion and drying systems | 1 | Permanent magnet cylinder | TCXT20 | 1 |

| 2 | Twin screw extruder | RCP125*2 | 1 | |

| 3 | Belt dryer | HGJW2000*4 | 1 | |

| Cooling packing system | 1 | Rotary grading screen | SFJH100*2 | 1 |

| 2 | Countercurrent Cooler | SKLN17X17 | 1 | |

| 3 | Rotary grading screen | SFJH100*2 | 1 | |

| 4 | Automatic packing equipment | / | 1 | |

The main fish feed production equipment used in the fish feed production line

RICHI MACHINERY

Other related feed production projects in the Philippines

2 t/h Shrimp Feed Production Line

3-4 t/h Aquatic Feed Production Line

5 t/h Animal Feed Production Line

RICHI MACHINERY

Why choose us?

Customizable aquatic feed production projects

RICHI can customize fish feed pellet machine and fish feed production lines according to the specific needs of each customer, such as local raw materials in the Philippines, characteristics of aquaculture, local voltage, plant size, investment budget, etc.

For investors who want to invest in aquatic feed mills and feed mills in the Philippines, we can provide each investor with feasible suggestions and the best investment plan based on our years of experience in the Philippines.

Professional fish feed production equipment manufacturer

With 29 years of experience in feed pellet production equipment manufacturing, we can provide customers with high-quality fish feed production equipment and fish feed production line turnkey projects.

In addition to high-quality equipment, we can provide customers with detailed information related to fish feed production equipment, including: process design, plant layout, feed plant installation and commissioning, as well as on-site training on electrical control, equipment operation, animal feed processing technology and formulation.

Comprehensive services

For pre-sales service, our engineers will design a suitable fish feed production plan according to the requirements; for in-sales service, our production department will promptly synchronize the relevant progress of the feed production equipment to customers; for after-sales service, we provide a one-year warranty, accessories support and permanent after-sales service.

The comprehensive services give our customers greater peace of mind when cooperating with us.

Strong strength

Over 50,000 square meters of modernized workshops, CE/ISO and other international certifications, and 27 patent certificates ensure that each of our feed production equipment meets production needs.

At present, our feed production projects and pellet production projects have covered 127 countries and regions around the world. If you need, you can contact us to check our feed production projects!

RICHI MACHINERY

RICHI serves customers around the world

Founded in 1995, RICHI has been serving Europe, America, Africa, the Middle East, Asia and other regions for nearly 30 years. The feed production equipment and pellet production equipment produced by RICHI are exported to many countries and regions in the world.

As the professional feed making machine manufacturer and pellet production equipment manufacturer , RICHI focuses on the design and manufacture of 1-100 t/h feed production projects and 1-50 t/h wood pellet production projects, and is committed to creating high-quality feed and pellet production projects for global customers.

No matter which country you are from, as long as you have feed production or pellet production needs, you can contact us at any time and communicate with us in detail about your needs and plans.

2000+

client

200+

project

180+

Exporting Countries

24h

24/7 service