RICHI in world

fish feed making machine in indonesia

RICHI MACHINERY

RICHI is the leader in fish feed making machine in indonesia

As the world’s leading fish feed making machine manufacturer and aquatic feed production project service provider, we have built a number of feed production projects and aquatic feed production projects in Indonesia.

RICHI MACHINERY

Why does Indonesia need fish feed making machine?

Problems facing aquaculture in Indonesia

As an important part of aquaculture, aquatic feed directly determines the development speed of the aquaculture industry and the quality of aquatic products produced.

There are three main problems facing the production of aquatic feed in Indonesia. The first is the shortage of raw materials for feed. Currently, most of the raw materials used in the aquatic feed production are imported. The second is that with the expansion of the aquaculture industry, more aquatic feed is needed to support the development of aquaculture. The third is that aquatic feed is too dependent on imports and the price is high, so it is urgent to produce it by ourselves.

As for the shortage of feed raw materials, the Indonesian government is studying and has proposed feasible solutions, such as using palm kernel meal instead of fish meal, etc. As for the shortage of aquatic feed, it is necessary to introduce high-quality fish feed making machine.

Indonesia’s aquaculture market has huge potential

Indonesia is currently the world’s second largest aquaculture producer. Indonesia has 17,500 islands and 81,000 kilometers of coastline, of which about 26.61 million hectares can be used for aquaculture.

The rich aquatic resources enable Indonesia to produce about 16.6 million tons of aquaculture products each year, mainly including: tilapia, catfish, milkfish, carp, shrimp, prawns, etc.

Strong support from the Indonesian government

In the future, Indonesia’s aquaculture industry will reach US$39.5 billion, creating 8.9 million jobs for Indonesian citizens, and Indonesia is committed to developing the country into the world’s largest producer of South American shrimp.

In order to meet the expected goals and boost the rapid development of the aquatic feed production sector, the Indonesian government has introduced a series of measures to encourage the problems of aquatic feed production, such as launching the “Fish Feed Self-sufficiency (GERPARI) Program”. The program aims to produce more low-priced, high-quality fish feed.

RICHI MACHINERY

RICHI fish feed making machine in indonesia

High-quality aquatic feed requires high-quality fish feed making machine. RICHI feed pellet production equipment has entered the Indonesian market since 2014, and it has been a full ten years now.

Over the past decade, many customers from Indonesia have purchased feed making machine , fish feed making machine, wood pellet production equipment, and turnkey aquatic feed production lines from us. Our feed making machine and wood pellet production equipment have been highly praised in Indonesia, which is one of the key factors for RICHI to become a leader in the field of aquatic feed production in Indonesia.

In 2018, we built the first aquatic feed production line in Indonesia, which means that RICHI fish feed making machine officially entered the Indonesian market. After six years of development, RICHI fish feed making machine has become an important partner in promoting the development of Indonesia’s aquaculture industry.

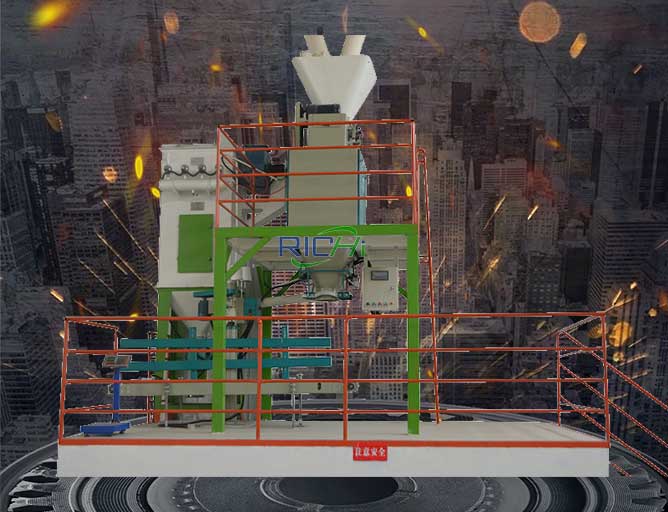

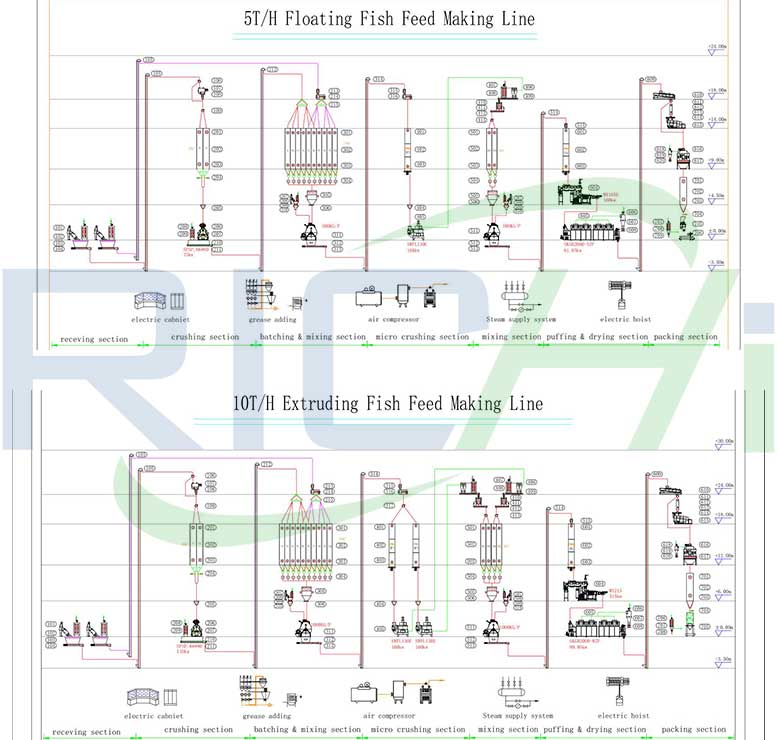

Below are two turnkey feed production line projects among the many feed production projects and pellet production projects we have built in Indonesia:

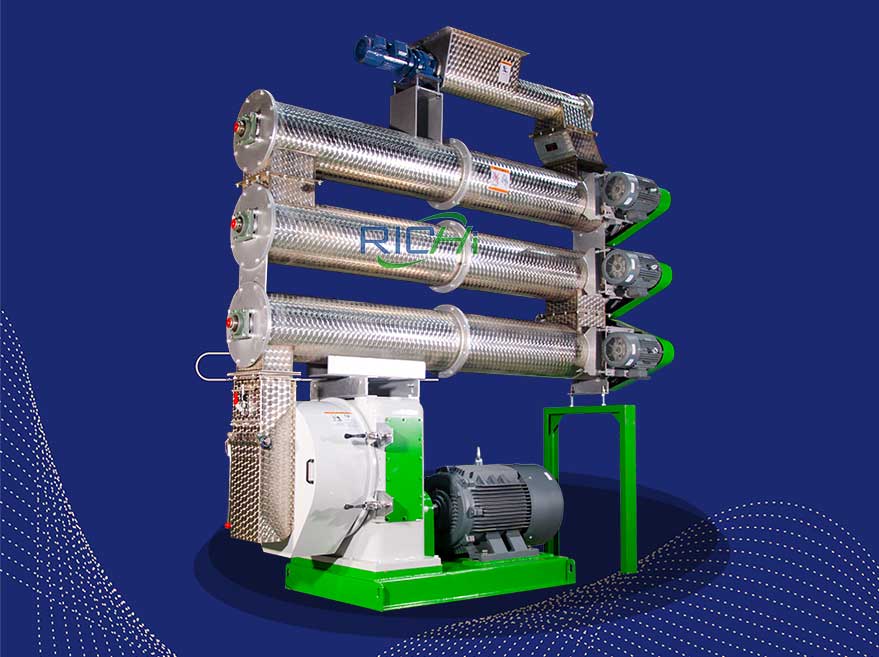

5 t/h floating fish feed production line in Indonesia

Feed Type: Floating Fish Feed

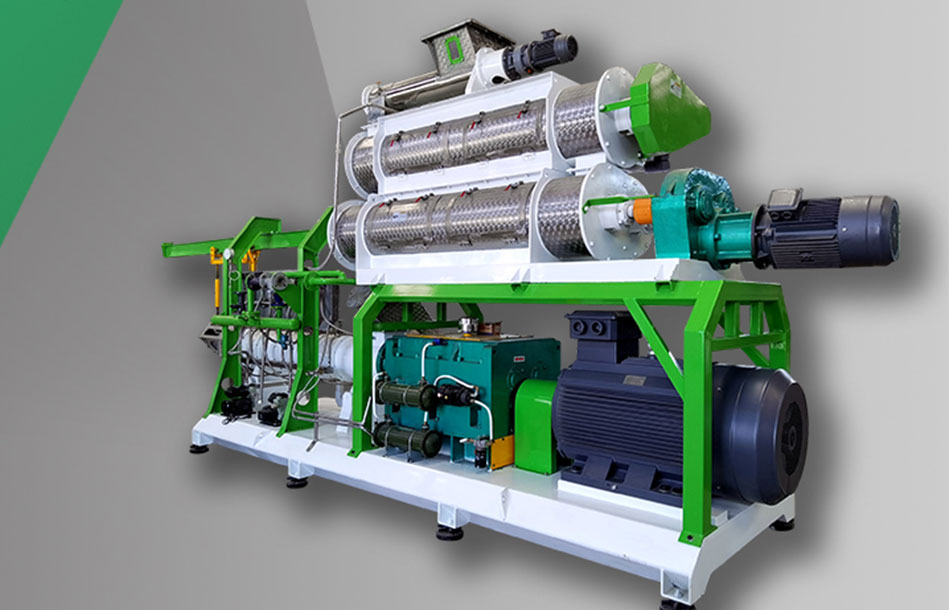

The main equipment needed for the floating fish feed production line: Twin-screw Extruder SPHS150*2,Feed Mixer 1000kg/p,Hammer Mill SFSP66*60,Ultrafine Grinder SWFL130E,Box-type Circumfluent Dryer SKGD2000-5ZP,Feed Pellet Cooler,Feed Pellet Packing Machine

Project Description: The aquatic feed production project was invested and built by a well-known feed manufacturer in Indonesia, aiming to improve the quality of local aquatic feed in Indonesia.

This feed manufacturer has built feed mills in many countries around the world, so it has rich production experience in the field of feed production. During the negotiation process with us, when their head saw our engineers’ design plan for the aquatic feed production line, he decided to make us their partner in investing and building feed mill in Indonesia.

This aqua feed production line is equipped with twin screw extruder to produce high quality floating fish feed.

2 t/h shrimp feed production line in Indonesia

Feed Type: Mainly used to produce shrimp feed

The main equipment needed for the floating fish feed production line: Batching bin*10,Hammer Mill*2 SFSP 56*40,Feed Mixer,Feed Pellet Machine With Three-layer Modulator,Feed Pellet Cooler,Packing machine

Project Description: This project is fully automatic shrimp feed production line, including fully automatic batching system and fully automatic packing system. The entire shrimp feed production line is relatively compact in design.

A pelletizer with three-layer adjuster is used to produce shrimp feed pellets. In order to meet the special needs of a certain shrimp and crab breeding factory, a special shrimp feed crusher is equipped, which can crush the shrimp feed pellets to 0.6mm.

RICHI MACHINERY

Equipment needed in aquatic feed production in Indonesia

Indonesia’s demand for aquatic feed mainly includes two aspects: fish feed and shrimp feed. According to the output of Indonesia’s aquatic products, Indonesia’s demand for fish feed mainly includes tilapia feed, catfish feed, carp feed, and milkfish feed; the demand for shrimp feed mainly includes shrimp feed.

As world-renowned fish feed making machine manufacturer, RICHI can provide high-quality fish feed making machine for Indonesian aquatic feed producers based on the local breeding status and future development trends in Indonesia.

Tilapia Fish Food Extruder

Among Indonesia’s aquatic product production, tilapia ranks first with a share of nearly 30%.

RICHI can provide 0.5-14 t/h tilapia feed extruder. The extruded feed produced by this tilapia feed extruder can meet the growth needs of local tilapia in Indonesia.

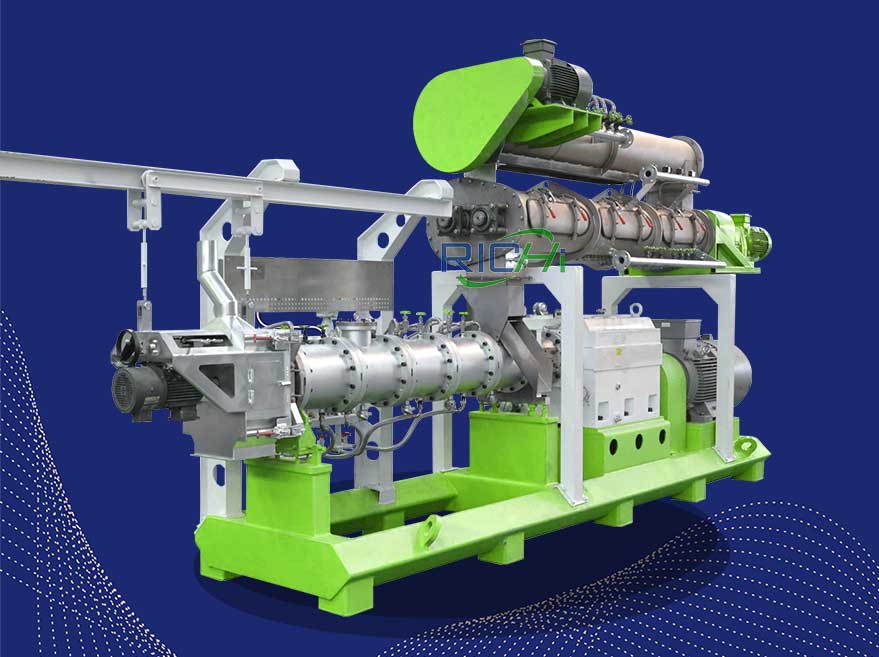

Catfish Feed Making Machine

Catfish occupies an important position in Indonesia’s aquatic products.

As professional fish feed making machine manufacturer, RICHI can provide high-quality catfish feed making machine.

Carp Feed Pellet Machine

The 1-20 t/h carp feed making machine developed by RICHI can produce fish feed pellets with size of 1-4 mm to meet the growth needs of carp.

Shrimp Feed Pellet Machine

The shrimp feed making machine with three-layer modulator is specially developed by RICHI for the production of shrimp feed. The equipment is economical and has high production efficiency. It is suitable for large and medium-sized shrimp feed mill.

Related fish feed making machine

Extrusion or pelleting is an important process in the production of aquatic feed. However, in order to obtain high-quality aquatic feed, in addition to aquatic feed pelletizers or aquatic feed extruders, grinders, mixers, coolers, screening equipment and packing equipment are also needed.

RICHI MACHINERY

Customizable 0.5-40 t/h fish feed making machine in indonesia

According to different investment needs, production needs and the size of the production site, RICHI can provide different customers with complete sets of fish feed making machine that meet their needs.

As professional turnkey fish feed making machine manufacturer, we can not only provide customers with feed pelletizing equipment or feed extrusion equipment, but also customize 0.5-40 t/h fish feed production lines for customers.

The customized fish feed production line includes all the equipment needed in the production line, such as storage equipment, raw material washing and receiving equipment, crusher, mixer, feed pelletizer, feed extruder, cooler, packing equipment, etc.

Cleaning and receiving of raw materials

During the raw material processing stage, storage equipment, batching equipment, etc. are used.

Crushing Section

Crushing the granular raw materials into powder. The main equipment used is hammer mill, superfine grinder, etc.

Mixing Section

Mix all the raw materials evenly, the main equipment used is the mixer.

Pelleting or extrusion section

The mixed raw materials are made into pellets. The main equipment used is fish feed making machine or fish feed extruder.

Drying Section

The prepared particles are dried to a moisture content of about 13%, and the main equipment used is an belt dryer.

Cooling Section

The main equipment used to cool the particles to room temperature is the cooler.

Packing Section

According to the demand, the pellets are packed into bagged feed of fixed weight, and the main equipment used is the packing machine.

RICHI MACHINERY

Why choose us?

Perfect service system

RICHI has a complete service system. Whether it is pre-sales, sales, or after-sales, we have professional staff to connect with every customer.

After our pre-sales staff understands the customer’s needs, they will arrange professional design engineers and sales engineers to communicate with the customer about the fish feed making machine and determine the design plan for the fish feed making machine.

After the fish feed making machine is completed, we have professional staff to arrange transportation for your goods. No matter where your aquatic feed production project is located, we can transport the goods to your project location. Then we will install, train, debug, and operate it.

Rich industry experience

As the leader in the field of feed production, RICHI’s pellet production equipment has been exported to more than 120 countries and regions around the world, and RICHI’s fish feed making machine can be seen in many countries.

With nearly thirty years of industry experience, we are well aware of the needs of each customer and can design fish feed production lines that meet their specific needs. At the same time, we will also continuously improve our fish feed making machine according to the operation of each customer’s fish feed making machine to meet the development needs of the fish feed production field.

Professional production capabilities

RICHI currently has three modern factories and a production workshop of more than 30,000 square meters. The workshops have introduced advanced production equipment from home and abroad. Every staff member in the workshop has received professional training to ensure the quality of each of our fish feed making machine and all the equipment needed on the fish feed production line.

Advanced production equipment, professional staff, and rigorous production plans ensure that the fish feed making machine purchased by each customer can be completed before the delivery date, and delivered to the customer according to the agreed delivery time, allowing customers to quickly carry out fish feed production plans.

RICHI MACHINERY

RICHI serves customers around the world

Founded in 1995, RICHI has been serving Europe, America, Africa, the Middle East, Asia and other regions for nearly 30 years. The feed production equipment and pellet production equipment produced by RICHI are exported to many countries and regions in the world.

As the professional feed making machine manufacturer and pellet production equipment manufacturer , RICHI focuses on the design and manufacture of 1-100 t/h feed production projects and 1-50 t/h wood pellet production projects, and is committed to creating high-quality feed and pellet production projects for global customers.

No matter which country you are from, as long as you have feed production or pellet production needs, you can contact us at any time and communicate with us in detail about your needs and plans.

2000+

client

200+

project

180+

Exporting Countries

24h

24/7 service