fish Feed Making Machine

High-quality fish feed making machine

Customized fish feed production solutions

RICHI has extensive experience in the construction of fish feed mills.

Richi Machinery

How to make fish food pellets? What equipment is needed to produce fish feed? How to choose the right fish feed production solution? How to choose fish feed making machine with high cost performance?

As the world’s leading manufacturer of fish feed making machine, RICHI provides customers with professional aquatic feed production solutions and solves all problems encountered by customers in the aquatic feed production process through continuous research and innovation in aquatic feed extrusion technology, aquatic feed pelleting system, aquatic feed drying system, and aquatic feed spraying system.

Fish Feed Making Machine: Fish feed extruder, fish feed pelletizer, fish feed pellet dryer, fish feed sprayer, etc.

Fish Feed Production Solutions: Floating fish feed production line solutions, sinking fish feed production solutions, pet feed production solutions, shrimp feed production solutions, etc.

0.5-30

Capacity(ton/hour)

0.6-8

Feed pellet size(mm)

Complete set of fish feed making machine

High-end aquatic feed pellet usually requires the coordinated operation of multiple equipment to produce. RICHI can provide all the equipment required in the aquatic feed pellet production process to meet the needs of various aquatic species such as fish, shrimp, crabs, etc.

From raw material crushing equipment to extrusion and granulation equipment, as well as drying and packing equipment, we design, produce and manufacture them ourselves, so we dare to guarantee the quality of each equipment.

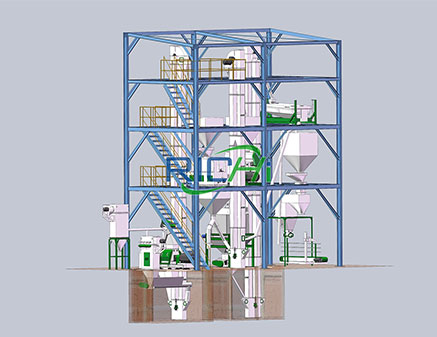

Complete solutions for fish feed pellet production

For commercial fish feed production, the complete feed production solution is the prerequisite for opening a fish feed plant and also the guarantee for the fish feed mill to make profits.

RICHI customizes reasonable fish feed production solutions according to different fish feed production needs. Currently, there are thousands of fish feed production solutions available for reference, and we continue to accumulate experience, innovate and develop on the existing basis, so we can quickly tailor fish feed pellet production solutions for you.

Fish Feed Making Machine Supplier

Learn in detail what equipment is needed in the fish feed pellet production process, including core equipment such as fish feed extruder machine and fish feed pelletizers used in the fish feed production process, as well as a series of auxiliary equipment such as crushers, mixers, dryers, spraying equipment, packing equipment, screening equipment, and conveying equipment.

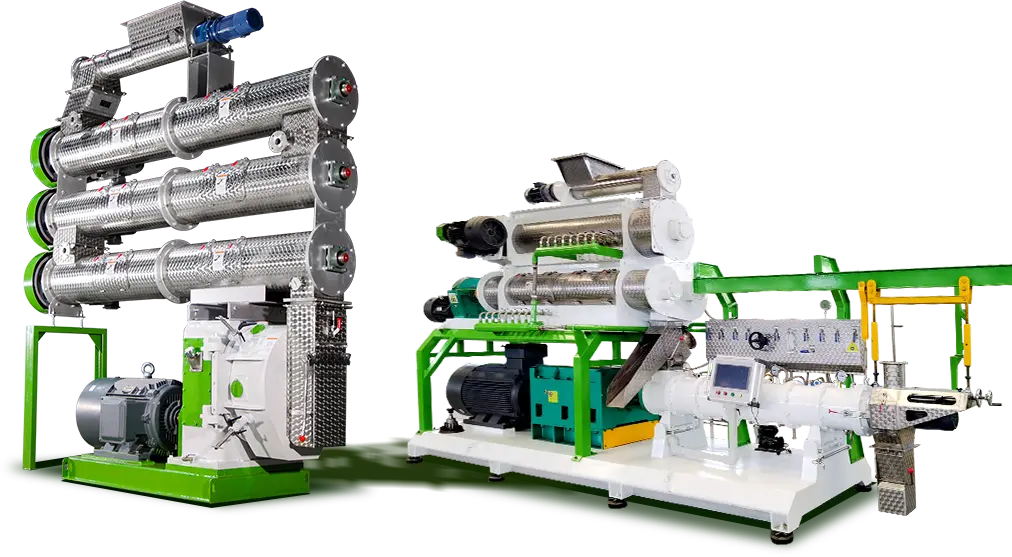

Feed Extruder Machine and Feed Pellet Mills

We provide fish feed extruders, fish feed pelletizers, shrimp feed pelletizers, and shrimp feed extruders suitable for various feed formulas. Whether it is the modulator used on the extruder or the ring die used on the pelletizer, it can be configured according to your actual production needs. So whether you want to produce floating fish feed, sinking fish feed pellet, or slow sinking fish feed, you can find feed extruder machine and feed pelletizers that meet your production needs at RICHI.

Fish feed extruder machine

Capacity: 0.3-12 tons/hour

Power: 15-355KW

By optimizing the extrusion process, the production needs of floating fish feed and sinking fish feed pellet can be achieved. The extruder can speed up the speed of raw materials passing through the extrusion chamber and improve the efficiency of the entire feed extruder machine.

Fish feed pelletizer

Capacity: 0.5-30 tons/hour

Power: 22-315KW

RICHI uses innovative fish feed pellet mills to meet the production needs of sinking fish feed pellet, which are widely used in sinking fish feed factories around the world.

Shrimp feed pellet machine

Capacity: 0.5-10 tons/hour

Power: 22-315KW

RICHI shrimp feed pellet machine is the shrimp feed making machine specially developed by RICHI for producing shrimp feed pellets. It is equipped with a three-layer modulator, which can well meet the production needs of shrimp feed pellet mill.

Features of RICHI Fish Feed Macking Machine

The number of screws of the extruder and the number of modulators of the pelletizer can be selected according to actual production needs.

The whole equipment is operated automatically, and management and maintenance are convenient and more user-friendly. The production efficiency is improved, and the overall operating cost is lower.

The gears are made of high-strength titanium alloy and are precision ground, with strong load-bearing capacity, low operating noise and high transmission efficiency.

SKF bearings are used to ensure smooth operation of the equipment and extend its service life.

The main drive adopts gear drive, which can increase production efficiency by 15% compared with belt drive.

Each machine is equipped with an independent electrical control system and safety shutdown function to protect the safety of workers.

Equipped with automatic grease lubrication system to achieve timing, quantitative and non-stop refueling.

Equipped with ultra-thin cutters specially designed for fish feed production, the cut surface of the produced fish feed particles is smoother.

The feed port adopts an adjustable soft sealing structure to effectively prevent the leakage of steam and dust.

Related Equipment For Fish Feed Pellet Production

Fish feed pellet production solutions

For fish feed mills, the quality of fish feed pellets is crucial if they want to stand out from the fish feed production industry and maximize the benefits of fish feed pellet production. RICHI can customize fish feed production solutions for you according to different types of fish and shrimp, as well as different stages of the growth process of fish and shrimp. We use our expertise to maximize your production needs and enable you to quickly start your fish feed production business.

Different types of fish feed production lines

According to the buoyancy of aquatic feed, we can provide floating fish feed production line, sinking fish feed production line and slow sinking fish feed production line for customers to choose. At the same time, we can also provide specific types of fish feed production solutions according to the growth and development needs of different types of fish, such as tilapia feed production line, trout feed production line, sturgeon feed production line, eel feed production line, perch feed production line, etc.

Uniquely designed fish feed pellet production solutions can meet your production needs to the greatest extent.

Floating fish feed production solutions

Our experience and expertise enables us to provide you with comprehensive advice and services throughout your entire floating fish feed production project.

Sinking fish feed pellet production

We have built several sinking fish feed pellet mills around the world. No matter where your project is located, we can provide you with corresponding support.

Tilapia Feed Production Solutions

According to the different production stages of tilapia, fish feed pellets of different sizes can be designed to be produced on the same fish feed production line to meet the feeding needs of tilapia.

Trout feed production line

From the design of trout feed production solutions to the production, manufacture and installation of trout feed production equipment, the complete trout feed production solution can help you quickly start your fish feed production business.

Sturgeon feed production solutions

At RICHI, you can get a full set of sturgeon feed pellet production equipment and sturgeon feed production turnkey projects with guaranteed quality and worry-free after-sales.

Eel feed production line

According to your actual production needs, RICHI can transform your eel feed production ideas into standardized design plans and put them into actual project production.

Seabass feed production solutions

RICHI provides high-quality services to global fish feed manufacturers with innovative sea bass feed production line designs and a full set of high-quality sea bass feed production equipment.

Design of fish feed plants with different capacity

RICHI provides multiple design solutions for fish feed factories with different outputs to meet the production needs of all fish feed manufacturers.

● 1-2 tons per hour

Fish feed production line

Taking into account the plant area, plant height and investment budget, the fish feed production line solution designed for large-scale aquaculture farms and fish feed production plants is favored by many fish feed manufacturers.

● 3-4 tons per hour

fish feed mill

RICHI has been committed to building 3-5 tons per hour fish feed factories for customers in need. It has accumulated a lot of mature experience in fish feed factory construction and can meet the various needs of 3-5 tons per hour fish feed producers in the production process.

● 5-7 tons per hour

floating fish feed plant

5-7 tons per hour automated fish production solutions are available, including the cooperation of multiple automated systems such as automatic batching and automatic packaging, which can effectively improve the production efficiency of the fish feed factory and maximize its benefits.

● 8-10 tons per hour

fish feed mill plant

The customized fish feed production line solution of 8-10 tons per hour can fully consider your actual production needs; the best fish feed factory production equipment can ensure the efficient and orderly operation of the entire fish feed factory.

● 10-12 tons per hour

fish food processing line

RICHI optimizes the fish feed production process, improves fish feed production equipment, and provides brand-new fish feed production line solutions for fish feed manufacturers.

● 12-15 tons per hour

fish feed pellet mill

The 12-15 tons per hour high-end fish feed production line solution can help you improve the quality of fish feed pellets, allowing you to quickly occupy the fish feed market share and maximize profits in the industry.

● 15-17 tons per hour

fish feed manufacturing plant

Based on the innovative, high-standard and systematic fish feed production line design process and based on your actual needs, we can customize a 15-17 tons per hour modern fish feed production line solution for you.

● 18-20 tons per hour

fish feed production plant

The 18-20 tons per hour turnkey fish feed production line project includes the planning and design of the feed factory, the design of the feed production line, the production and installation of fish feed production equipment, allowing you to start your fish feed production business with peace of mind.

How to Make Fish Food Pellets?

How to use the fish feed making machine mentioned above to produce fish feed? What is the complete process of producing fish feed? What steps are required to produce fish feed?

These are some of the doubts that fish feed producers may have in the early stage. The general process of producing fish feed is: cleaning and receiving raw materials – crushing and mixing – granulation or extrusion – drying – spraying – cooling – packing.

However, different fish feed plants will be equipped with different fish feed production processes according to actual production needs. Therefore, please tell us your fish feed production needs or fish feed production plan, and we will introduce the fish feed production process to you in detail.

Cleaning and receiving of raw materials

During the raw material processing stage, storage equipment, batching equipment, etc. are used.

Crushing Section and Mixing Section

Crushing the granular raw materials into powder and then mixing in a certain proportion.

Pelleting or extrusion section

The mixed raw materials are made into pellets. The main equipment used is fish feed making machine or fish feed extruder.

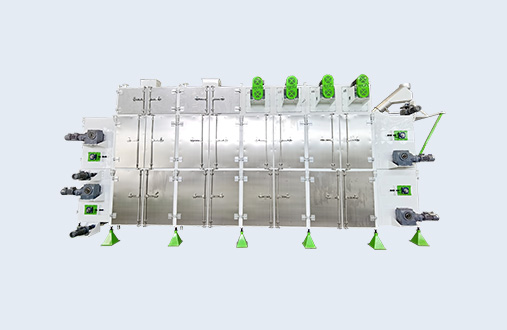

Drying Section

The prepared particles are dried to a moisture content of about 13%, and the main equipment used is an belt dryer.

Cooling Section

The main equipment used to cool the particles to room temperature is the cooler.

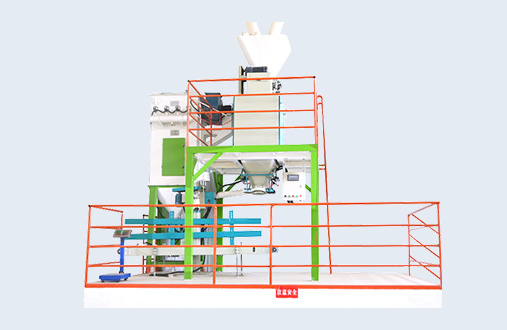

Packing Section

According to the demand, the pellets are packed into bagged feed of fixed weight, and the main equipment used is the packing machine.

RICHI fish feed production project

RICHI has a global layout and has built more than 200 feed production projects in more than 130 countries and regions around the world, including floating fish feed production projects, sinking fish feed production projects, poultry feed production projects, chicken feed production projects, cattle feed production projects, shrimp feed production projects, etc.

No matter what kind of feed pellets you want to produce? No matter what your raw materials are? No matter which country or region you are located in, RICHI can provide you with the right feed pellet production solutions with rich practical experience and open the door to the field of feed pellet production with you.

2 t/h aquatic feed production line in Iran

Feed Type: Floating fish feed pellets, shrimp feed pellets

The main equipment needed for the feed pellet line: 2 tons per hour twin screw extruder machine, feed pellet machine with three-layer modulator, crusher, ultrafine grinder, high square sieve, belt dryer, grease adding system, vacuum sprayer, packing equipment, etc.

Project Description: This feed pellet production project is located in Iran. The customer built this fish feed factory to produce fish feed for its own aquaculture farms and also sell part of the fish feed to make a profit.After the customer contacted us, he quickly determined that we were a professional aquatic feed pellet machine manufacturer, so he signed a contract with us after finalizing the design plan.

At present, the fish feed production line has been officially put into operation and is running well.

500kg/h fish feed pellet line in Cote d’Ivoire

Feed Type: Floating fish feed pellets

The main equipment needed for the fish feed pellet line: Fish feed extruder machine, feed mixer, drying equipment, drum sprayer, cooler, packing equipment.

Project Description: The customer has its own farm in Cote d’Ivoire and has high requirements for the quality of fish feed pellets, so it decided to introduce a 500kg/h high-end aquatic feed production line to meet the breeding needs of the farm.

Since the customer has many years of experience in purchasing aquatic feed pellets, he attaches great importance to the quality of feed production equipment.

5 t/h Fish Feed plant in Russia

Feed Type: Mainly fish feed

The main equipment needed for the fish feed production line: 5 tons per hour twin-screw extruder, crusher, ultrafine crusher, belet dryer, cooling equipment, vacuum spraying equipment, fully automatic packing system, fully automatic batching system.

Project Description: The project is located in Russia and mainly produces fish feed pellets. It is an investment project. For customers, this is a relatively large feed production project. Therefore, customers are very cautious when choosing partners. They came to our factory for a field visit and conducted face-to-face communication before determining the cooperation plan.

Relying on this fish feed production line, customers can use soybean meal, bran, fish meal, rice bran and other raw materials to produce fish feed with particle size between 0.5-8mm. At present, the production line has been fully installed and put into operation.

1-2 t/h Floating feed production line in Indonesia

Feed Type: Mainly used to produce floating fish feed

The main equipment needed for the floating fish feed production line: 2 tons per hour twin screw extruder machine, crusher, mixer, drying equipment, vacuum sprayer, packaging equipment, conveying equipment, dust removal equipment

Project Description: This fish feed pellet line is located in Indonesia and is mainly used to produce floating fish feed.

The customer combined the local market conditions and saw that the local demand for fish feed was increasing and the quality requirements for fish feed were also increasing. He believed that fish feed had a relatively large market and good prospects, so he decided to invest in this field.

The customer came directly to our factory to discuss the construction of the fish feed production plant with us, and finally reached a cooperation with us.

Frequently Asked Questions

What is the price of aquatic feed production equipment?

Aquatic feed pellet production equipment includes feed extruder machine, feed pelletizers, grinders, mixers and other equipment. Each type of equipment includes a variety of different models and outputs. Therefore, there are large differences in the prices of aquatic feed production equipment, ranging from a few thousand dollars to tens of thousands of dollars, hundreds of thousands of dollars or even millions of dollars.

So if you want to know more detailed prices of fish feed making machine, you can tell us your specific needs so that we can calculate a detailed price for you.

What is needed to start fish feed production?

Starting fish feed production usually requires starting from the following aspects: production site, production equipment, and staff.

The first thing is to choose a suitable project site. The construction of a feed factory requires sufficient space. For example, a small fish feed factory generally requires about 500-1000 square meters, while a large fish feed factory requires more space. In addition, when choosing a project site, you must also consider conditions such as transportation, water and electricity supply, and drainage.

The second is the selection of fish feed production equipment. Purchase the corresponding fish feed production equipment according to production needs, such as fish feed extruder, fish feed pelletizer, raw material crushing equipment, mixing equipment, pellet drying equipment, etc.

Another thing is the recruitment and training of feed factory staff. Experienced technicians are recruited to be responsible for production and technical management. Operators are trained to be familiar with equipment operation and production processes.

In addition to the above aspects, if you want to start fish feed production, you also need to consider the source of raw materials, market research, the processing of various certificates and other related matters.

What equipment is suitable for making fish feed?

There are many kinds of equipment for making fish feed. Different types of fish feed production require different equipment, and different outputs of fish feed production also require different equipment. Generally speaking, the production of fish feed mainly requires: raw material crushing equipment, mixing equipment, extrusion equipment, granulation equipment, drying equipment, spraying equipment, cooling equipment, packing equipment, etc.

Through reasonable configuration, these equipments can efficiently produce high-quality fish feed to meet market demand.

Do you provide shipping and installation services?

We provide shipping and installation services to all our customers, and we can continue to provide our customers with peace of mind after-sales service.

RICHI MACHINERY

Why choose us?

Perfect service system

RICHI has a complete service system. Whether it is pre-sales, sales, or after-sales, we have professional staff to connect with every customer.

After our pre-sales staff understands the customer’s needs, they will arrange professional design engineers and sales engineers to communicate with the customer about the fish feed making machine and determine the design plan for the fish feed making machine.

After the fish feed making machine is completed, we have professional staff to arrange transportation for your goods. No matter where your aquatic feed production project is located, we can transport the goods to your project location. Then we will install, train, debug, and operate it.

Rich industry experience

As the leader in the field of feed production, RICHI’s pellet production equipment has been exported to more than 120 countries and regions around the world, and RICHI’s fish feed making machine can be seen in many countries.

With nearly thirty years of industry experience, we are well aware of the needs of each customer and can design fish feed production lines that meet their specific needs. At the same time, we will also continuously improve our fish feed making machine according to the operation of each customer’s fish feed making machine to meet the development needs of the fish feed production field.

Professional production capabilities

RICHI currently has three modern factories and a production workshop of more than 30,000 square meters. The workshops have introduced advanced production equipment from home and abroad. Every staff member in the workshop has received professional training to ensure the quality of each of our fish feed making machine and all the equipment needed on the fish feed production line.

Advanced production equipment, professional staff, and rigorous production plans ensure that the fish feed making machine purchased by each customer can be completed before the delivery date, and delivered to the customer according to the agreed delivery time, allowing customers to quickly carry out fish feed production plans.

RICHI serves customers around the world

Founded in 1995, RICHI has been serving Europe, America, Africa, the Middle East, Asia and other regions for nearly 30 years. The feed production equipment and pellet production equipment produced by RICHI are exported to many countries and regions in the world.

As the professional feed making machine manufacturer and pellet production equipment manufacturer , RICHI focuses on the design and manufacture of 1-100 t/h feed production projects and 1-50 t/h wood pellet production projects, and is committed to creating high-quality feed and pellet production projects for global customers.

No matter which country you are from, as long as you have feed production or pellet production needs, you can contact us at any time and communicate with us in detail about your needs and plans.

2000+

client

200+

project

180+

Exporting Countries

24h

24/7 service