Completed Cases

1.5-2T/H Extruding Fish & Shrimp Feed Production Line in Iran

Project Name

Fish And Shrimp Feed Production Line

Country

Iran

Capacity

1.5 – 2 tons per hour

Application

Used to produce fish feed, shrimp feed, floating feed and sinking feed

RICHI MACHINERY

Project Introduction

This feed pellet production project is located in Iran and is mainly used to produce fish feed pellet and shrimp feed pellet, including both floating fish feed pellet and sinking fish feed pellets and shrimp feed pellets. This feed production line can produce 1.5-2 tons of extruded feed or 5-6 tons of sinking feed pellets per hour.

This client is a well-known aquatic product processor in Iran, mainly engaged in the processing of various fish products and the export of shrimps. Aquatic products are exported to many countries in the world, including Australia, Canada, Germany, China, etc.

At the beginning of 2022, they decided to start the business of aquatic feed production. Since they are engaged in the aquatic processing industry, they are relatively professional in the production of aquatic feed pellet. Therefore, when they are looking for aquatic feed pellet machine manufacturers, they can quickly identify the professionalism of the machinery manufacturers.

After the customer contacted us, he quickly determined that we were a professional aquatic feed pellet machine manufacturer, so after finalizing the design plan, he signed a contract with us.

The feed pellet production line is currently in operation, and the fish feed pellet it produces is not only for their own use but also sold to many aquaculture farms.

RICHI MACHINERY

Finished Pellet

The main raw materials used in this fish feed pellet line are fish meal, bran, rice bran, soybean cake, silkworm pupa powder, shrimp head powder and some vitamins, premixes, additives, oils and other substances that need to be added to the feed.

These raw materials pass through the fish feed production line anThese raw materials can be processed into fish feed and shrimp feed of different sizes of 1-8 mm through the feed pellet line.

Salmon

trout

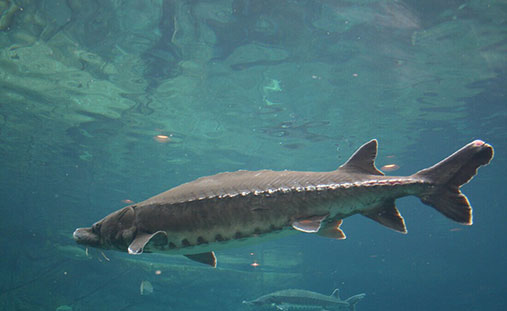

Sturgeon

Cod

Fish feed

Fish feed pellet

Fish feed feeding

Shrimp Feed Pellet

RICHI MACHINERY

Process of Feed Production Line

This fish feed pellet line is a fully automatic fish and shrimp feed production line. The entire production process, from receiving and cleaning raw materials to crushing, extrusion/pelleting and packing, has a very high degree of automation, especially the packing section. The customer finally decided to use a fully automatic packing machine, which greatly saved manpower and improved the production efficiency of the feed pellet mill.

And because the customer’s site had height restrictions, we changed the design plan many times, and finally changed the aquatic feed pellet line that required a height of more than 20 meters to 8 meters.

When producing extruded aquatic feed, pellets are pelletized using feed extruder. The main production stages and processes are as follows:

Crushing System

Mixing System

Extrusion System

Drying System

Cooling System

Packing System

01

Crushing System

After being cleaned by the cleaning equipment and impurities in the raw materials are removed by the impurity removal equipment, the raw materials are sent to the hammer mill through the frequency conversion feeder.

RICHI

02

Mixing System

The crushed raw materials are fed into the mixer, and at the same time, premix, oil and water are added into the mixer through the small material feeding port. All raw materials in the formula are evenly mixed in the feed mixer.

RICHI

03

Extrusion System

The main purpose of using aquatic feed extruder is to produce extruded feed. This customer uses the extruder to produce floating fish feed. The mixed raw materials are made into extruded pellets of different sizes through the extruder.

RICHI

04

Drying System

The moisture content of the extruded feed is high, which is not easy to store and is prone to mold and deterioration, so it needs to be dried in a dryer. The moisture content of the feed after drying in the drying machine is about 11%, which can meet the requirements of long-term storage.

RICHI

05

Cooling System

The dried feed is sprayed with a spraying machine. This is mainly to increase the fat content. After the surface of the feed is coated with a layer of oil, it can also improve the water resistance of the feed.

After spraying, the feed enters the cooler for cooling to room temperature.

RICHI

06

Packing System

The processed feed pellet is screened by the screening equipment. After screening, the qualified feed pellets are packaged into 10-50 kg bagged feed by the packaging machine.

Packaged feed pellets are easier to store, use and sell.

RICHI

The main raw materials used in this fish feed When producing sinking feed pellet such as shrimp feed pellet, the process flow is: crushing section, mixing section, pelleting section, post-ripening section, cooling section, and packing section.

The production process of the equipment used in the crushing section, mixing section, cooling section, and packing section is very similar to the production process of extruded feed, but the pelleting section and post-ripening section are two sections that are different from the production of extruded feed and are needed to produce shrimp feed pellet:

Pelleting System

The equipment used to produce sinking aquatic feed pellet such as shrimp feed pellet is shrimp feed pellet machine with three-layer modulator. The mixed raw materials are modulated and pelletized in the pellet machine, and then cut into sinking feed pellets of different lengths.

Post-ripening System

The raw materials have been matured once in the modulator during the pelleting process. However, in order to meet the growth and development needs of aquatic organisms such as shrimp, the feed coming out of the pellet mill needs to be matured for the second time, and a maturer is needed at this time.

Production Process of Machine in The Workshop

Since this fish feed pellet and shrimp feed pellet production line is completely custom designed according to customer needs, many equipment on the feed pellet line, such as feed pellet machine, spraying machine, etc. and some auxiliary equipment, need to be produced according to the design.

So after the contract was signed, our production workshop immediately developed a 60-day production plan for this project. During the two-month production process, we will regularly send customers some pictures and videos of finished or semi-finished equipment, so that customers can understand our production process from beginning to end.

RICHI MACHINERY

Delivery and Installation

Delivery

After all the feed pellet equipment is produced within 2 months, we will ship it according to the delivery time communicated with the customer in advance.

Delivery is a very important link. We have complete delivery process, and our equipment has been exported to more than 100 countries and regions in the world. So no matter where your project is built, we can ensure that the equipment is delivered to your project location.

Installation

After the machines were delivered, we sent two engineers to the site to provide After the goods were delivered, we sent two engineers to the site to provide installation guidance. After the installation was completed, we provided training and guidance to the staff of the feed pellet mill. We have complete installation process, installation drawings, and detailed operating specifications, so the installation process for this customer was relatively smooth.

RICHI MACHINERY

After-sales Service

After the fish feed and shrimp feed pellet line was installed, we arranged professional after-sales staff to communicate with customers and help them solve all problems encountered during the production process.

The warranty pThe warranty period of this fish feed and shrimp feed pellet line is one year. Within one year, no matter what problems occur with the feed production equipment, our after-sales staff will help customers actively solve them.

In addition to the one-year warranty period, we provide permanent online service, which means that in the subsequent feed production process, no matter what problems customers encounter, they can contact us at any time. In the subsequent feed production process, if customers need to replace various accessories, they can find us at any time, and all accessories are original equipment.

RICHI MACHINERY

Why choose us?

Customized Design

According to the customer’s site, production and other needs, our professional engineers have designed more than ten solutions, constantly improved the drawings, modified the process, added special designs, etc., and finally customized a solution that fully meets the customer’s production needs.

Rich experience

Our company was founded in 1995 and has nearly 30 years of production experience in the feed machinery industry. Whether it is a single feed production machine or complete turnkey feed production project, we can provide perfect feed production solutions.

Professional service team

From early stage communication, to solution design, to equipment production and after-sales service, we have a team with very complete service, and every member of the team is doing their best to complete this project.

Competitive strength

We have a production workshop of more than 30,000 square meters, and customers can visit our factory at any time. At present, our equipment has been exported to more than 120 countries and regions all over the world, and customer satisfaction is very high.

RICHI MACHINERY

What feed processing solutions can we provide?

We can design and build complete feed pellet production lines and turnkey feed pellet mills with capacity of 1-100 tons per hour for all types of aquatic organisms and animals.

Aquatic feed production line

Floating feed, slow sinking feed, sinking feed……

Pet food production line

Cat, dog, turtle, fox……

Livestock feed production line

Cow, sheep, pig, horse……

Poultry feed production line

Chicken, duck, goose……