Extruded Feed Dryer Machine

RICHI extruded feed belt dryer is the feed-specific belt dryer developed on the basis of ordinary dryers. It is highly targeted at drying extruded feed pellet and has the high drying efficiency.

Capacity: 2-12 tons per hour

RICHI MACHINERY

Why extruded feed needs to be dried

Normally, the moisture content of the finished feed pellets after extrusion is relatively high. Taking floating fish feed as an example, the moisture content of the feed pellets coming out of the fish feed extruder is usually around 20%. In order to prevent the extruded aquatic feed from deteriorating during storage, its safe storage moisture content is generally controlled below 13%, so it is necessary to dry it to remove excess moisture in the extruded feed.

Therefore, it is necessary to set up a special drying process section in the feed production process and equip it with professional drying equipment to achieve the purpose of extruded feed drying.

RICHI MACHINERY

Introduction of RICHI belt dryer

RICHI extruded feed belt dryer is specially designed and combined with decades of experience, it designs and manufactures the best quality extruded feed drying machine for users, which can meet the drying needs of extruded fish feed, pet feed, grain pellets and other pellet materials.

For example, energy consumption is significantly reduced compared to comparable We can provide users with individual drying machine or drying systems, as well as complete fish feed production lines and pet food production lines.

Equipment details of RICHI extruded feed belt dryer:

Automatic Control System

The operating parameters of drying medium quantity, temperature, humidity and exhaust gas circulation volume can be independently controlled.

Independent unit segment composition

Each unit section has independent circulation and forced ventilation, which effectively increases the circulating air volume, resulting in high hot air penetration and high heat utilization rate.

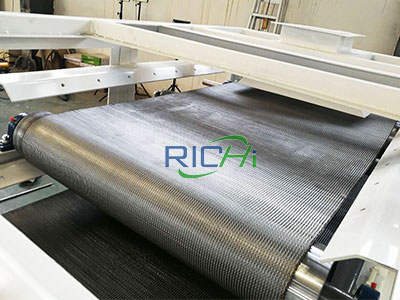

Imported PET woven mesh belt

Imported PET woven mesh belt is used for conveying, which has high ventilation efficiency and improves drying efficiency by more than 25%.

Swinging fabric feeder

Adopt swing distributor, the material is evenly distributed and the moisture is evenly distributed.

Can’t Find Belt Dryer You Want?

Contact Us To Customize For You!

RICHI MACHINERY

Applications of Belt Dryer

The extruded feed belt dryer developed by RICHI has been widely used in the field of extruded feed drying. It is the guarantee for feed mill to produce high-quality extruded feed, accelerating the development of aquaculture and improving the quality of pet food.

The following are the more common application areas of belt dryers. Of course, in addition to the products in these fields, belt dryers may also be used in other fields. As long as your product has drying requiremExtrusion feed belt dryer is mainly used in fish feed mill, shrimp feed factory, pet food factory, etc., and other feed production equipment together to form a complete feed production line.

Fish Feed Mill

The fish feed extrusion process has gradually matured, and extruded feed occupies a very important position in the fish feed market, and is still developing in a positive direction. The extruded feed belt dryer is a necessary equipment for producing high-quality fish feed.

Shrimp Feed Pellet Mill

The use of puffing technology to produce shrimp feed has become a necessary condition for the production of high-end shrimp feed. RICHI has developed professional shrimp feed belt dryer for the drying of shrimp feed, which can minimize the breakage of pellet.

Pet Feed Mill Plant

Drying is a very important process in the processing of pet food. RICHI extruded feed belt dryer can effectively ensure the flavor and color of pet feed after drying, and can achieve the purpose of long-term storage and reduce the deterioration of pet feed.

RICHI MACHINERY

Models of RICHI extruded feed belt dryer

The following are the parameters of some common models of extruded feed belt dryers we produce, with capacity of 2-12 tons per hour. Of course, we can also provide extruded feed belt dryers with other capacity according to the specific needs of users.

Want to know more detailed information about extrusion feed belt dryer, please contact us now, we will customize the appropriate dryer according to each customer’s needs.

Parameter table of extruded feed belt dryer

| No. | NAME | CAPACITY (T/H) | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | |||||

| 1 | Drying machine(Full stainless steel ) | 2~3 | WDWS150-4/2 | 1 | 44.30 | 44.3 |

| 2 | Drying machine(Full stainless steel ) | 3~4 | WDWS200-4/2 | 1 | 49.80 | 49.8 |

| 3 | Drying machine(Full stainless steel ) | 5~7 | WDWS200/5-4 WDWS220/4-4 | 1 | 53.20 | 53.2 |

| 4 | Drying machine(Full stainless steel ) | 8~12 | WDWS220/5-4 | 1 | 71.80 | 71.8 |

RICHI MACHINERY

How does the extrusion feed belt dryer work?

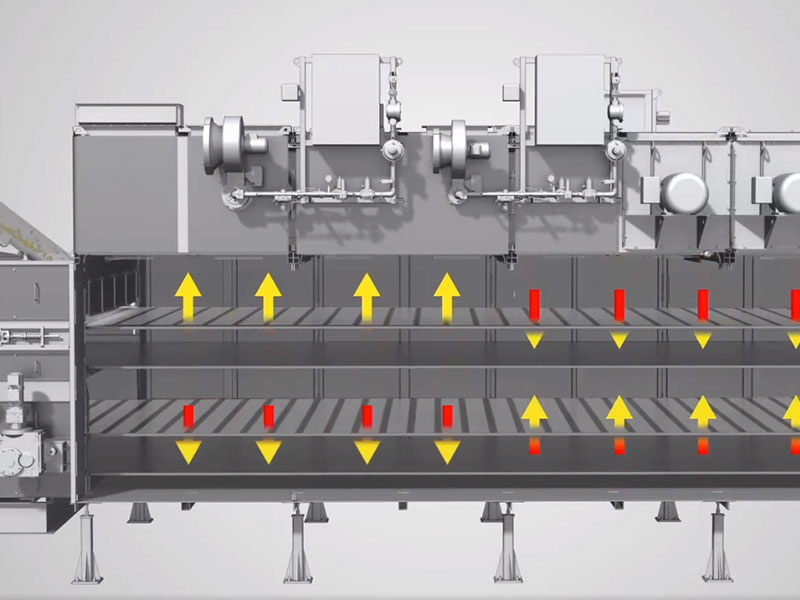

Belt dryer is a commonly used continuous drying mahcine, which consists of a material conveying mechanism and one or more separate drying chambers. Each drying chamber is composed of a box, a heating system, a hot air circulation system, and an exhaust system.

When the extruded feed belt dryer is working, the feed coming out of the feed extruder is transported to the adjustable speed mesh belt through the material conveying mechanism. The hot air flows through the mesh belt and the air space of the extruded feed from top to bottom. In this process, the dry gas takes away the moisture of the material, thereby achieving the purpose of drying.

Currently common dryers include single-layer, multi-layer extrusion feed belt dryers and single-stage, multi-stage extrusion feed belt dryers. Users can choose according to their actual needs.

Can’t Find Belt Dryer You Want?

Contact Us To Customize For You!

RICHI MACHINERY

How to process high quality poultry pellets?

RICHI belt dryer has been widely used in the drying process of feed RICHI belt dryer has a simple structure and is commonly used for drying grains, feeds, and momi cakes. It is especially widely used in the drying process of feeds and has been recognized by many feed mill. The main reasons are as follows:

1. During the drying process, the extruded feed moves together with the conveyor belt, and the relative positions of the extruded feeds are relatively fixed, so the drying time of each extruded feed is basically the same, and the drying uniformity is high;

2. The extruded feed is in a semi-suspended state on the entire screen surface of the belt dryer, which can not only ensure the drying effect of the material, but also minimize the breakage of the extruded feed pellet;

3. The moisture content and color of the feed coming out of the extruder are uniform. After being dried by the belt dryer, the moisture and color uniformity of each extruded feed pellet can still remain basically consistent;

RICHI MACHINERY

Our belt dryers in successful use

Iran

Extrusion Feed Belt Dryer in Iran

Dryer Model: WDWS200-4/2

Capacity: 3-4 tons per hour

Project Description: The customer purchased a complete aquatic feed production line from us, mainly used to produce floating fish feed and shrimp feed. We equipped this feed production line with an extruded feed belt dryer, which makes the moisture content of the finished feed pellets around 10%-11%.

Russia

Extrusion Feed Belt Dryer in Russia

Dryer Model: WDWWS220/4-4

Capacity: 5-6 tons per hour

Project Description: The extruded feed dryer is used in 5-6 ton floating fish feed production lines. It can dry the extruded feed pellets from 20% moisture content to 10%-11% to achieve the purpose of long-term storage.

extruded feed belt dryer can be customized

Each customer has different production needs, production site requirements, investment requirements, etc. RICHI can customize professional extrusion feed belt dryer for each customer.

RICHI belt dryers have a wide range of accessories that can be selected to help ensure smooth operation of the belt dryer with minimal maintenance.

- Hot air recirculation can reduce the energy required to heat the dryer;

- Using inverter-controlled fans helps reduce the energy consumed by the belt dryer;

- Rotating agitator ensures even drying of the product;

- Belt cleaning system to help prevent belt breakage;

- Muffler, helps reduce the noise from the fan.

RICHI MACHINERY

Other applications of RICHI belt dryer

As a professional belt dryer manufacturer, our belt dryer can be used not only for drying extruded feed, but also for drying in many other industries, such as chemical, food, pharmaceutical, building materials and other industries. It is especially suitable for drying flake, strip and granular materials with good air permeability.

Wood Drying Industry

It caIt can be used to dry various wood and wood-related products, such as wood chips, wood shavings, wood, sawdust, shavings, etc. It has a good drying effect on wood and is convenient to use.

Agricultural Product Drying Industry

Drying of all agricultural products and agricultural waste, such as corn, soybeans, barley, wheat and other grains, as well as forage grass, alfalfa, straw, sunflower shells, palm shells, etc.

Pellet

IIn addition to extruded feed pellets, there are alIn addition to drying extruded feed pellets, it can also dry poultry feed pellets, and biomass pellets, such as sawdust pellets, sunflower seed shell pellets, etc.

RICHI MACHINERY

How to choose a belt dryer

1. How to deliver the belt dryer to my project location?

RICHI has a professional transportation team. The staff responsible for delivery are always tracking the transportation information of the equipment and will synchronize it to the customer as soon as possible, so there is no need to worry about the transportation of the belt dryer.

At present, all the equipment produced by RICHI has been exported to more than 120 countries and regions in the world. No matter where your project is located, we can transport the equipment to your project location.

2. What are the factors that affect the drying effect of the belt dryer?

Drying is a complex process, which is affected by many factors, such as drying time, hot air temperature, hot air volume, etc., which will affect the final drying effect. The quality of drying is mainly judged from two factors: the moisture content of the dried product and the uniformity of the moisture content of the dried product.

For the drying of extruded feed, the composition and physical properties of the material also have a great influence on the final drying effect:

- If the feed formula contains a high proportion of oil, it is not conducive to drying;

- When feed particles are dense, it is not conducive to the diffusion of water inside the particles along the capillaries to the surface of the pellet;

- Larger pellet size requires longer drying time;

- All feed pellet sizes should not vary too much, otherwise it will be difficult to obtain a good drying unevenness index;

- Generally speaking, sinking feed is more difficult to dry than floating feed.

A high-quality belt dryer is the result of the comprehensive effect of all components in the drying system, including the dryer, auxiliary mechanical devices, thermal energy system, air duct system, electrical control system, etc. Therefore, when choosing a belt dryer manufacturer, you need to find one with rich experience and strong production capacity.

3. What are the precautions when using the belt dryer?

RICHI belt dryer is a modern intelligent device with simple operation, but there are still some precautions during use. Only by using the belt dryer correctly can a more ideal drying effect be achieved.

- Pay attention to the impact of high temperature on the nutritional value of extruded feed. Drying requires heat. Within the allowable limit, the higher the temperature, the more conducive to improving the efficiency of the dryer. However, under high temperature conditions, the nutritional value of the feed will be affected, such as non-enzymatic browning. Therefore, for extruded feed pellets generated by special feed formulas, it is possible to consider keeping the feed in a high temperature (100℃~200℃) environment for several minutes during drying to quickly heat the pellets. After that, the hot air temperature should be lowered to complete the remaining drying operations.

- Avoid rapid water loss from the surface of the particles in the early stages of drying, which would form a “water seal” and damage the capillaries connecting the surface and interior of the particles, thus preventing the moisture in the core of the particles from eventually diffusing outwards.

- The drying process of any material takes a certain amount of time. During a drying process, the operating parameters should not be changed frequently, and a certain amount of reaction time should be given to the dryer. Only in this way can the optimal operating parameters for a certain material be obtained.

4. Can you only provide extruded feed drying equipment? I want to purchase extruded feed drying equipment and feed production equipment.

We can not only produce drying equipment, provide customers with belt dryers and complete belt systems, but also are a professional manufacturer of feed and pellet production equipment, providing extrusion feed production equipment, poultry feed production equipment, biomass pellet production equipment, as well as feed turnkey projects and pellet turnkey projects. So if you want to buy a complete set of feed production equipment, you can contact us directly.