Dry Type fish feed extruder

RICHI dry type fish feed extruder can be used for the production of fish feed, shrimp feed, cat feed, dog feed, crab feed, turtle feed and other feed.

Capacity: 0.5-12 T/H

fish feed extruder manufacturer

Fish feed extruder is a kind of equipment which uses extrusion technology to produce fish feed pellets, so fish feed extruder is also called, fish feed extruder machine, feed extruder, etc.

As the professional feed making machine manufacturer, RICHI’s dry type fish feed extruder is mainly used to produce aquatic feed pellets and pet food pellets of different shapes and lengths of 0.6-8mm.

In these years, RICHI fish feed extruder machine has won the trust of many customers with its high-end quality, and has become the first choice for various large-scale extrusion feed plants, medium-sized extrusion feed plants and small extrusion feed plants. Whether you focus on the performance of fish feed extruder, the quality of the extruded feed pellets produced, or the efficiency of fish feed extruder, we can provide the most suitable fish feed extruder.

Model of RICHI fish feed extruder

RICHI can provide various models of Fish feed extruder machine with different capacitys

| Model | Capacity (t/h) | Machine Power (kw) | Feeding Power (kw) | Dia. of Screw (mm) | Cutting Power (kw) |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

fish feed extruder with different capacities

The common capacity range of fish feed extruder is 0.1-4 tons per hour, which is the models listed in the above parameter table. However, for large extrusion feed factories, RICHI can also provide fish feed extrusion machine with corresponding capacity.

For nearly three decades, RICHI has always focused on the research of aquatic feed production, providing extrusion feed mills with fish feed extruder of different capacitys and fish feed production line solutions of 0.5-40 tons per hour with leading technology and high-end quality.

100-500 kg/h fish feed extruder

Small-volume fish feed extruder is suitable for small investors in the field of aquatic feed production, as well as farms of aquatic organisms such as fish, shrimp, etc.

1 ton fish feed making machine

1-2 t/hour fish feed extruder can be widely used to produce high-quality aquatic feed extrusion pellets and pet food pellets that meet the production needs of various aquatic organisms and pets.

2 tons fish feed extruder

RICHI 2-3 tons/hour fish feed extruder has different designs to choose from, 2-3 t/h single screw extruder, 2-3 t/h twin screw extruder, etc.

3 tons fish feed extruder machine

RICHI is constantly improving its R&D capabilities. The 3-4 t/h fish feed extruder machine provided by RICHI adopts the extrusion system independently developed by RICHI and has been successfully applied to many large fish feed production plants.

Application of fish feed extruder

RICHI fish feed extruder can be used to produce a variety of feed pellets

RICHI fish feed extruder machine is to mix corn, fish meal, soybean meal, meat and bone meal, silkworm pupae and other raw materials in a certain proportion and then extrude them to obtain feed pellets.

Normally, we think that fish feed extruder machine is used to produce fish feed pellet, which is of course a very correct idea. However, in addition to producing fish feed, RICHI dry type fish feed extruder can also be used to produce many other types of extruded feed to meet the feeding needs of shrimp, cats, dogs, birds, rabbits, foxes and other animals, as well as the production of special types of feed such as ornamental fish, fish bait, and fish fry.

The demand for producing a variety of feeds can be met by adjusting the parameters of the fish feed extruder machine or replacing the parts of the equipment.

Extruded fish feed production

It can process a variety of different types of raw materials and is suitable for various fish feed formulas, so that the fish feed pellets processed by the fish feed extruder can meet the production needs of salmon, trout, sturgeon, tilapia, etc.

Shrimp Feed Pellets Production

It can produce shrimp feed pellets that sink to the bottom of the water and can remain in the water for a long time without being easily deformed, so as to meet the production needs of different types of shrimps and crabs.

Pet food production

RICHI fish feed extruder can produce pet food in different shapes and sizes to meet the feeding needs of some pets such as cats, dogs, turtles, etc.

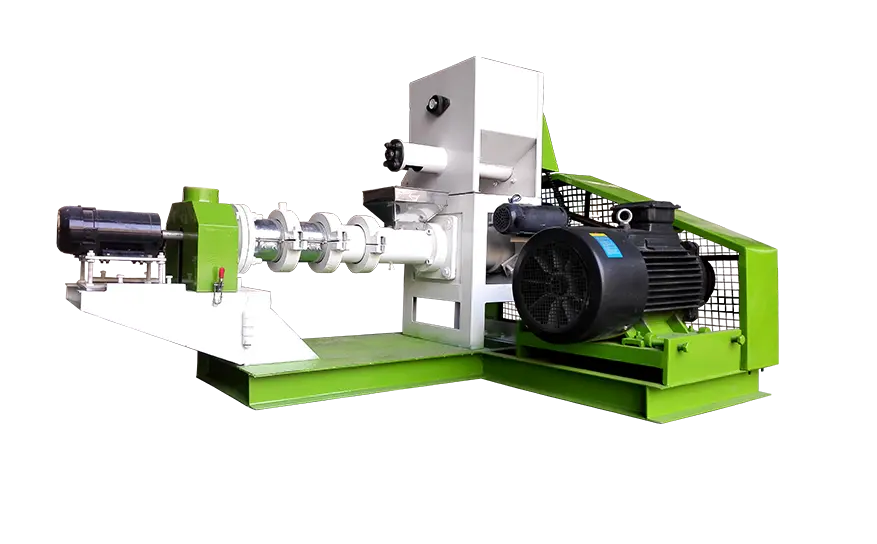

Working principle of fish feed extruder

RICHI dry type fish feed extruder is mainly composed of a feeding device, modulator (optional), screw (the number of which can be selected), pressurizing chamber, forming template, cutter, driving system and control system.

The raw materials mixed according to the proportions on the feed formula enter from the feed port, and undergo solid conveying, melting, and homogenization processes in the screw, turning the loose material into continuous plastic agglomerates. They are then extruded and mixed in the extrusion chamber, and then pass through the molding template and cutter to form extruded feed pellets of the required size and length are formed.

With advanced extrusion structure, the feeder adopts variable frequency motor to control the speed, and the speed can be adjusted freely; the whole fish feed extruder has novel and unique design, simple structure, convenient installation, disassembly and operation; the screw bushing and screw are made of special wear-resistant high-temperature alloy steel material, which has the advantages of wear resistance and long service life after heat treatment.

Advantages of using fish feed extruder for aquafeed production

RICHI fish feed extruder has many advantages in producing aquatic feed pellet

Wide range of applications

RICHI fish feed extruder can not only produce fish feed, but also shrimp feed, pet food, etc. It can be applied to the processing of a variety of raw materials and applied in multiple feed production fields.

Feed pellets are nutritious

RICHI fish feed extruder can be applied to the production of a variety of fish feed formulas. The fish feed pellets produced according to the feed formula can ensure its nutrient richness to the maximum extent.

Improve the stability of feed pellets

Extruded feed pellets are very stable in water and can remain in water for 12 hours or even 24 hours without deforming or melting, allowing aquatic organisms enough time to eat.

Improve feed conversion rate

The materials are treated with instantaneous high temperature in the fish feed extruder, and the resulting feed particles are more conducive to the digestion and absorption of feed by aquatic organisms such as fish and shrimp.

Feed density can be controlled

By adjusting the parameters of the fish feed extruder, feed pellets with different densities such as floating feed pellets, sinking feed pellets, slow sinking feed pellets, etc. can be produced to meet various feeding needs.

Feed pellets are safer and more hygienic

The high-temperature extrusion of the screw is equivalent to a pasteurization process. Harmful bacteria in the raw materials will be eliminated during the extrusion process, thereby reducing the impact of feed on aquatic animals and pollution to water quality.

Complete fish feed production line

— Richi Machinery —

fish feed extruder is mainly used in fish feed production lines and fish feed mills. For industrial fish feed production, continuous and efficient production is required. A single fish feed extruder obviously cannot meet the production needs of fish feed. Therefore, we can provide customers with 0.5-40 tons per hour fish feed production solutions according to customer needs.

The production process of the customized fish feed production line is: raw material receiving and processing – first crushing and first mixing – second crushing – second mixing – extrusion – drying – spraying – cooling – packing. (Not every feed production project needs to be equipped with all of the following sections. All of our sections are modularly designed and can be added or reduced according to your specific needs.)

Receiving and handling of raw materials

Equipped with a reasonable raw material receiving and storage system

First crushing and first mixing

Coarse crushing of raw materials and first mixing

Second crushing

The ultra-fine grinder crushes the raw materials to above 80 mesh

Second mixing

Mix the trace elements, premixes, etc. in the feed formula with the crushed bulk feed.

Extrusion

The material is extruded by the fish feed extruder machine to form expanded feed pellets.

Drying

Dry the extruded feed pellets with a moisture content of 18%-20% to a moisture content of 10%-11%

Spraying

Increase the oil content of feed pellets by spraying with a drum sprayer or vacuum spraying machine

Cooling

Cool to room temperature in a cooler to increase the hardness of the particles for subsequent processing

Packing

Packed into 10-50 kg bags for easy storage, use or sale

RICHI Cases

— Richi Machinery —

RICHI serves customers all over the world. The feed pellet making machine designed and produced by RICHI has been exported to 128 countries and regions in the world. More than 200 feed production plants built by RICHI have improved the quality of local feed pellets and created better economic benefits for customers.

1.5-2 t/h fish and shrimp feed mill in Iran

Feed type: Fish feed, Shrimp feed

The feed production project is designed to be about 8 meters high according to the customer’s site requirements, including crushing section, mixing section, granulation section, cooling section and packaging section. According to the customer’s requirements, the granulation section is equipped with feed pelletizer and feed extruder machine, so it can produce fish feed, shrimp feed, and poultry feed.

2 t/h fish feed production line in Indonesia

Feed type: Fish feed

The fish feed production project is equipped with a fully automatic packaging system in the packing section, which can effectively improve the production efficiency of the fish feed factory and save manpower. And due to the particularity of the customer’s raw materials, the twin-screw extruder is equipped in the extrusion section to meet the customer’s production needs.

3-5 t/h pet food production line in Canada

Feed type: Cat food, dog food, pet food, etc.

The pet food production line is a turnkey pet food production project. From the design of the feed production line to the planning of the plant, the production and transportation of equipment, the installation of the feed production line, etc., RICHI will send professional staff to connect with customers in each link. The feed production line can produce pet feed in various shapes.

5 t/h fish feed pellet mill in Uzbekistan

Feed type: Floating fish feed and sinking fish feed

This feed production line is mainly used to produce sinking fish feed, equipped with fully automatic raw material receiving system, fully automatic batching system and fully automatic packaging system. After the feed pellet mill entered orderly operation, the customer found us again and planned to expand the production scale of the feed factory and start producing floating fish feed pellets.

Customized fish feed production line solutions

— Richi Machinery —

Customized fish feed production solutions can help different customers realize their fish feed pellet production needs. While meeting the fish feed production needs, it can also improve production efficiency, reduce production costs, and maximize profits.

With rich experience and advanced technical capabilities, RICHI has provided customers with hundreds of fish feed production solutions of different capacitys. In the process of communicating with customers, we can always quickly understand the customer’s raw materials, site size and height restrictions, local production needs, etc., so as to customize the design of feed pellet mills that meet the production needs of customers based on these production characteristics.

If you want to start a fish feed production business, you can refer to some of the fish feed production solutions we have designed. Contact us to customize your fish feed production solution.

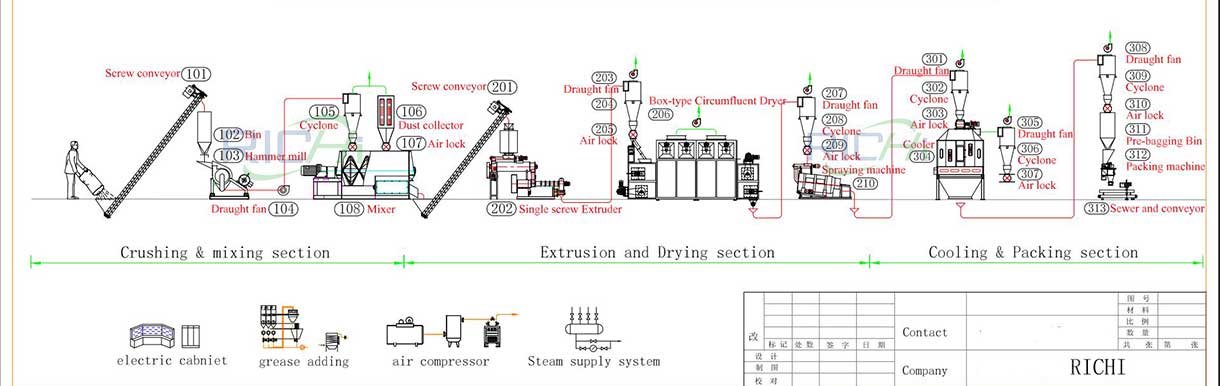

0.5 t/h fish feed production line

Feed Pellet Mill Scale: 0.5 tons per hour, 1,500 tons per year (based on 10 working hours per day and 300 working days per year)

Production Process: Crushing & Mixing Section-Extrusion and Drying section-Cooling & Packing Section

Feed Mill Structure: production workshop, finished product warehouse, etc. Small fish feed factory, suitable for aquaculture farmers and small fish feed investors.

Main Fish Feed Production Equipment: Hammer Mill,Mixer,Single Serew Extruder,Box-type Circumfluent Dryer,Spraying Machine,Cooler,Packing Machine

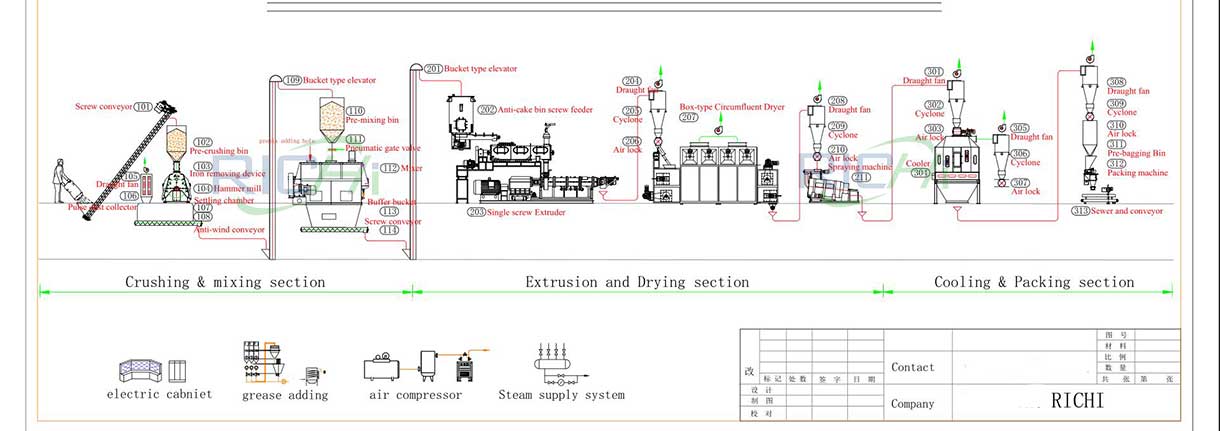

1-2 t/h fish feed production line

Feed Pellet Mill Scale: 1-2 tons per hour, 3000-6000 tons per year

Production Process: Crushing & Mixing Section-Extrusion and Drying section-Cooling & Packing Section

Feed Mill Structure: Raw material storage room, production workshop, finished product warehouse, etc. It can meet the needs of continuous fish feed production and is suitable for fish and shrimp farms, pet feed factories, and fish feed factories, etc.

Main Fish Feed Production Equipment: Hammer Mill,Mixer,Single Serew Extruder,Box-type Circumfluent Dryer,Spraying Machine,Cooler,Packing Machine

3-4 t/h fish feed production solution

Feed Pellet Mill Scale: 3-4 tons per hour, 9000-12000 tons per year

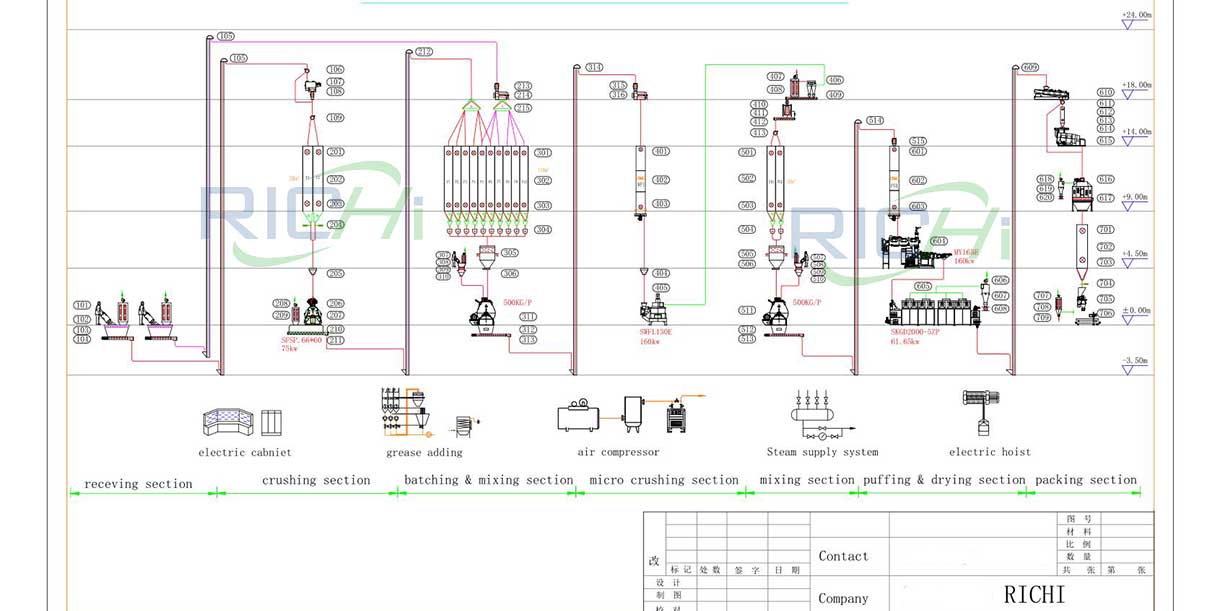

Production Process: Storage bin section-Receving section-Crushing section-Batching section-Micro-crushing section-Second mixing section-Extruding & Drying section-Packing section

Feed Mill Structure: Silo system, batching system, production workshop, office, finished product workshop, etc. The fully automated fish feed production line, which can automatically batch ingredients, automatically pack, etc., is a modern fish feed pellet production system.

Main Fish Feed Production Equipment: Silo,Hammer Mill,Mixer,Feed Extruder,Box-type Circumfluent Dryer,Spraying Machine,Batching scale,Cooler,Packing Machine

5 t/h fish feed pellet production line

Feed Pellet Mill Scale: 5 tons per hour, 15,000 tons per year

Production Process: Receving section-Crushing section-Batching & mixing section – Micro-crushing section-Mixing section puffing & drying section – Packing section

Feed Mill Structure: Raw material storage room, finished product workshop, production workshop, office, etc. Commercial fish feed production plant is suitable for fish feed manufacturers and investors who want to invest in fish feed production business.

Main Fish Feed Production Equipment: Hammer Mill,Mixer,Feed Extruder,Box-type Circumfluent Dryer,Spraying Machine,Batching scale,Cooler,Packing Machine

10 t/h fish feed production line

Feed Pellet Mill Scale: 10 tons per hour, 30,000 tons per year

Production Process: Receving section-Crushing section-Batching & mixing section – Micro-crushing section-Mixing section puffing & drying section – Packing section

Feed Mill Structure: Production workshop, office building, warehouse, raw material storage room, finished product workshop, etc. Large fish feed production line, fish feed production plant can be customized according to production needs, including the design of the entire feed pellet mill such as office building and production workshop.

Main Fish Feed Production Equipment: Hammer Mill,Mixer,Fish Feed Extruder,Box-type Circumfluent Dryer,Spraying Machine,Batching scale,Cooler,Packing Machine

ABOUT RICHI MACHINERY

Richi Machinery Co., Ltd. was founded in 1995 and is a comprehensive company integrating industry and trade. Specializing in animal feed pellet machine, aquatic feed pellet machine, wood pellet machine, grain storage systems and steel structure buildings, the R&D and production of aquatic feed pellet machine is a very important part of our business.

Since its establishment, adhering to the corporate vision of “creating a first-class enterprise, cultivating first-class talents, and making first-class contributions,” we have built the well-known “RICHI” brand in the industry. It is currently changing the image of Chinese products in the world with extremely high-quality products and services.