RICHI in world

Current Status of Shrimp Feed Pellet Production in Ecuador

As major shrimp farming country, Ecuador is the largest shrimp producer in Latin America, and its shrimp production accounts for more than half of the shrimp production in the Americas. It is also the world’s second largest white shrimp exporter.

Ecuador has tropical climate and shrimp can be raised all year round. The superior natural conditions have created a suitable environment for aquaculture industry, making fisheries an important source of economic support for Ecuador. At the same time, fisheries are also an important source of employment in Ecuador.

Shrimp feed pellet is an important factor affecting shrimp farming. The quality of shrimp feed pellet directly affects the growth and yield of shrimp. Therefore, with the emergence of more and more industrial shrimp farming plants, the quality of shrimp feed is particularly important.

In recent years, a number of world-renowned feed manufacturers have begun to invest in the construction of shrimp feed production plants in Ecuador, effectively promoting the development of Ecuador’s shrimp farming industry.

In the process of rapid improvement in the quality and output of shrimp feed pellet in Ecuador, as world-renowned feed production equipment manufacturer, according to the current situation of shrimp farming in Ecuador, we actively provide shrimp feed production equipment and shrimp feed production lines to support shrimp farming in Ecuador.

RICHI MACHINERY

RICHI can provide high-quality shrimp feed pellet machine to Ecuador

More than 95% of Ecuador’s aquaculture is marine shrimp, followed by tilapia. Other species, such as freshwater fish and crustaceans, are only farmed on small scale.

According to the aquaculture characteristics of Ecuador, RICHI can provide shrimp feed extruder and shrimp feed pelletizer to produce shrimp feed pellet.

shrimp feed extruder

Shrimp feed extruder is the main equipment needed when using extrusion process to produce shrimp feed pellet. RICHI can provide single screw shrimp feed extruder and twin screw shrimp feed extruder to process high protein and high fat content raw materials, suitable for all kinds of small, medium and large shrimp feed mill.

shrimp feed pelletizer

Shrimp feed pelletizer is the main equipment needed when using the pelletizing process to produce shrimp feed pellet. RICHI developed shrimp feed pelletizer with three-layer modulator based on the characteristics of shrimp feed pellet, which can effectively extend the modulation time, improve the modulation effect, increase the gelatinization and maturity of raw materials, and produce high-quality shrimp feed pellets.

RICHI MACHINERY

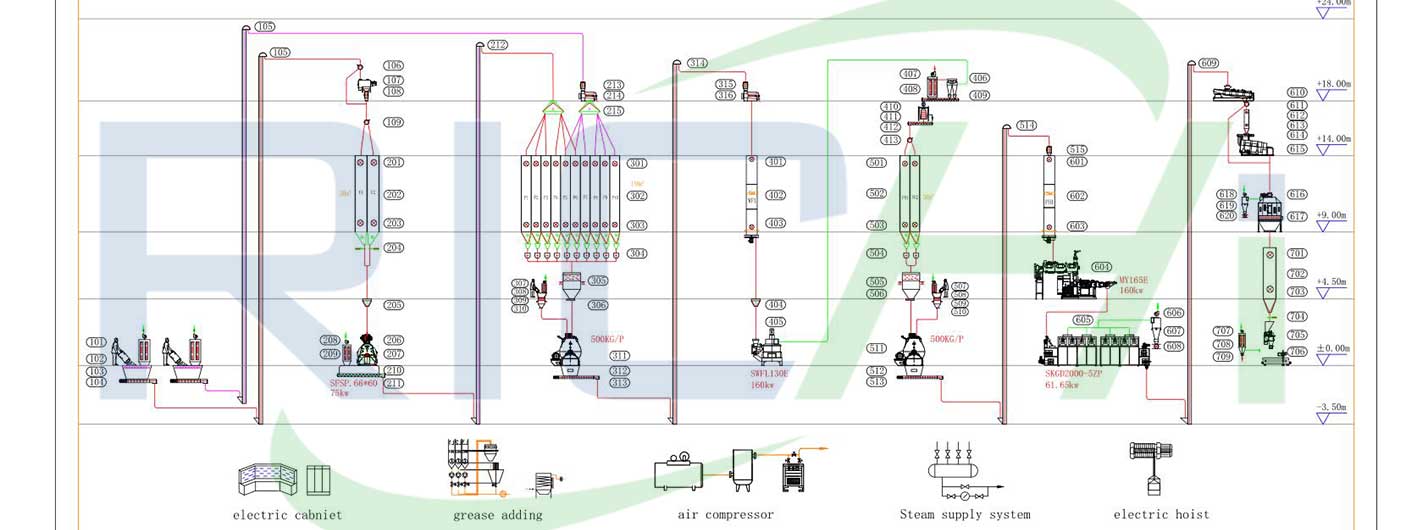

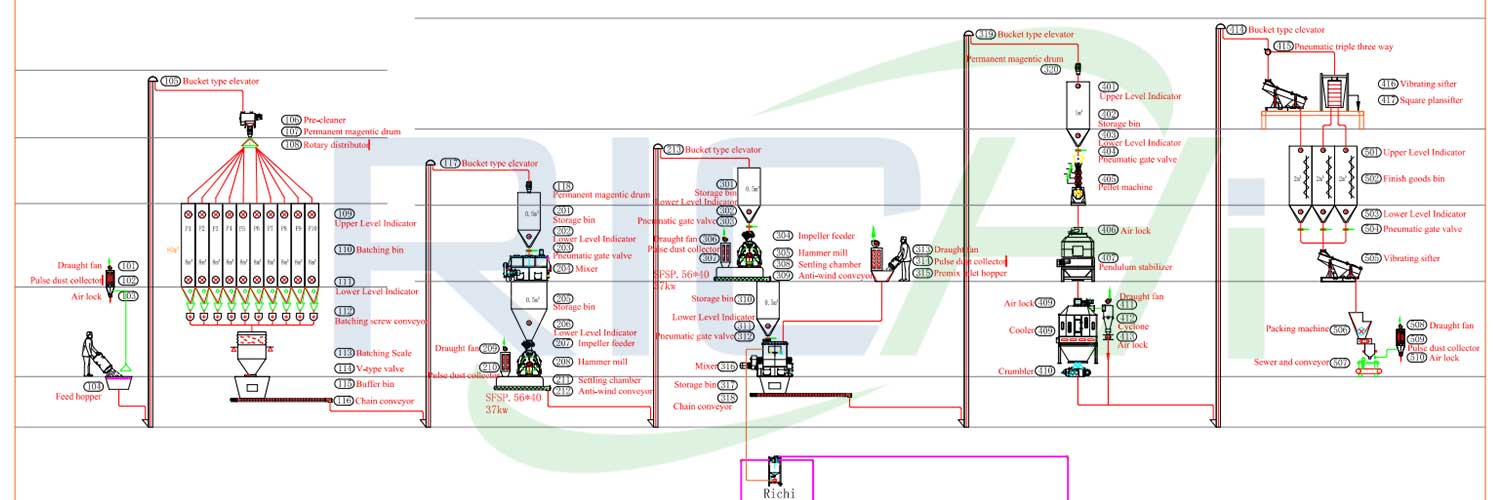

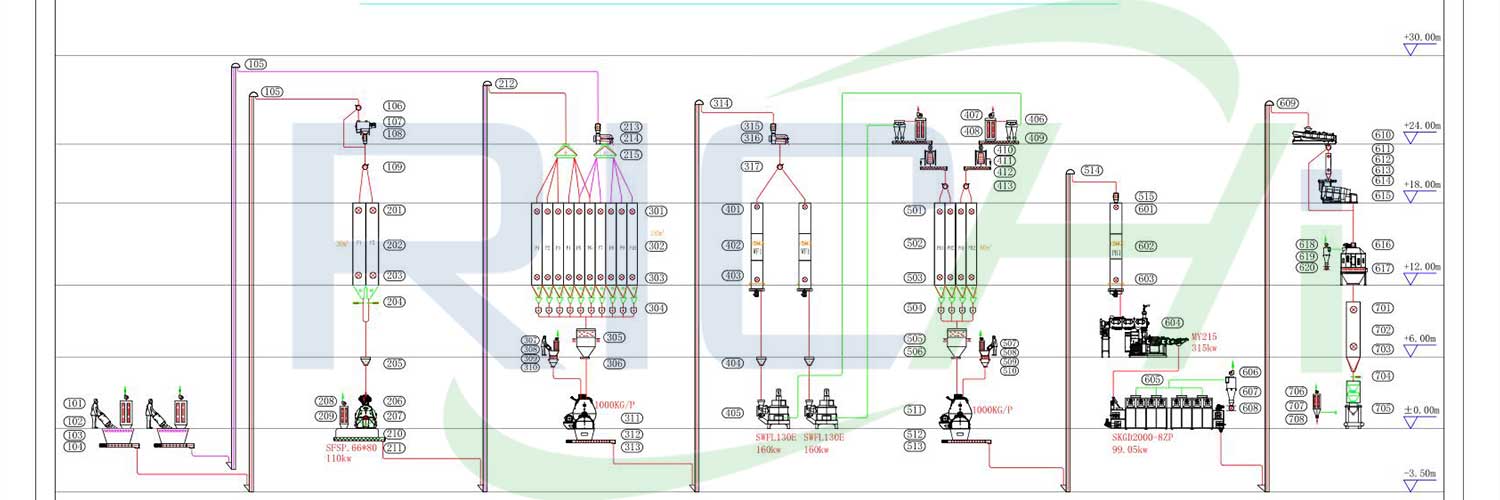

5 t/h shrimp feed production line in Ecuador

As feed pellet production equipment manufacturer, RICHI has shipped several feed pellet production equipments and feed pellet production lines to Ecuador. This 5 ton per hour shrimp feed pellet production line is a turnkey feed pellet production project that we built in Ecuador.

This shrimp feed pellet production project was invested and built in Ecuador by a world-renowned feed manufacturer. After comparing various options, the feed manufacturer decided to cooperate with us to build this shrimp feed pellet mill, aiming to develop the Ecuadorian shrimp feed pellet market and improve the quality of Ecuadorian shrimp feed pellet.

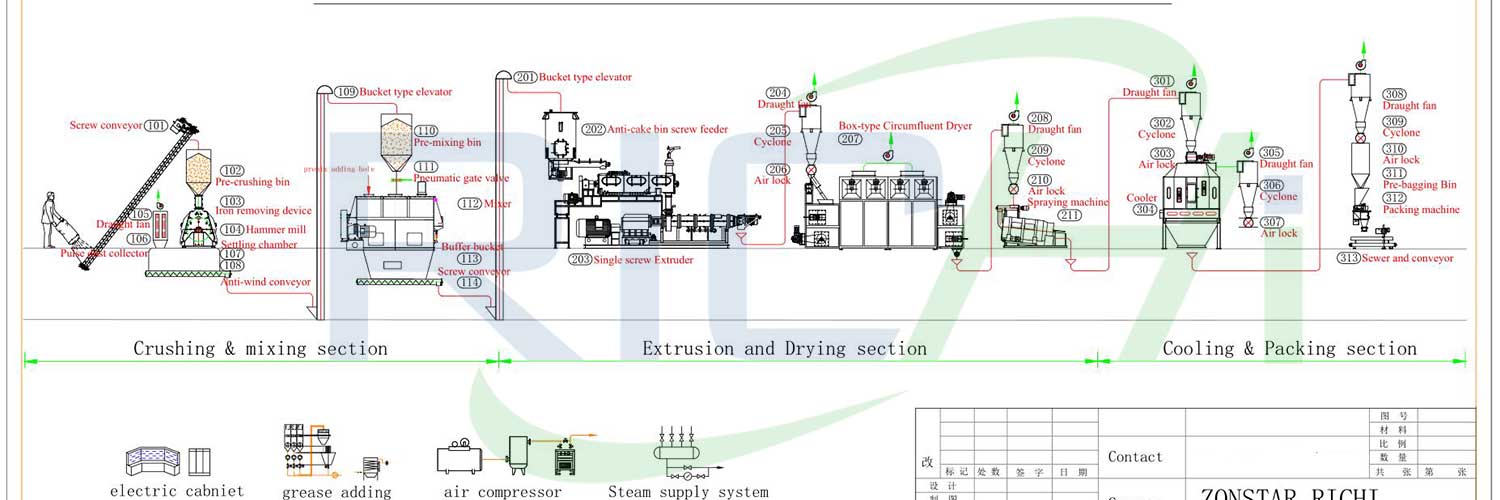

This shrimp feed pellet production line uses extrusion technology to produce shrimp feed pellet, which can accurately control the length and sedimentation of shrimp feed pellet and produce shrimp feed pellet with high protein and high fat content.

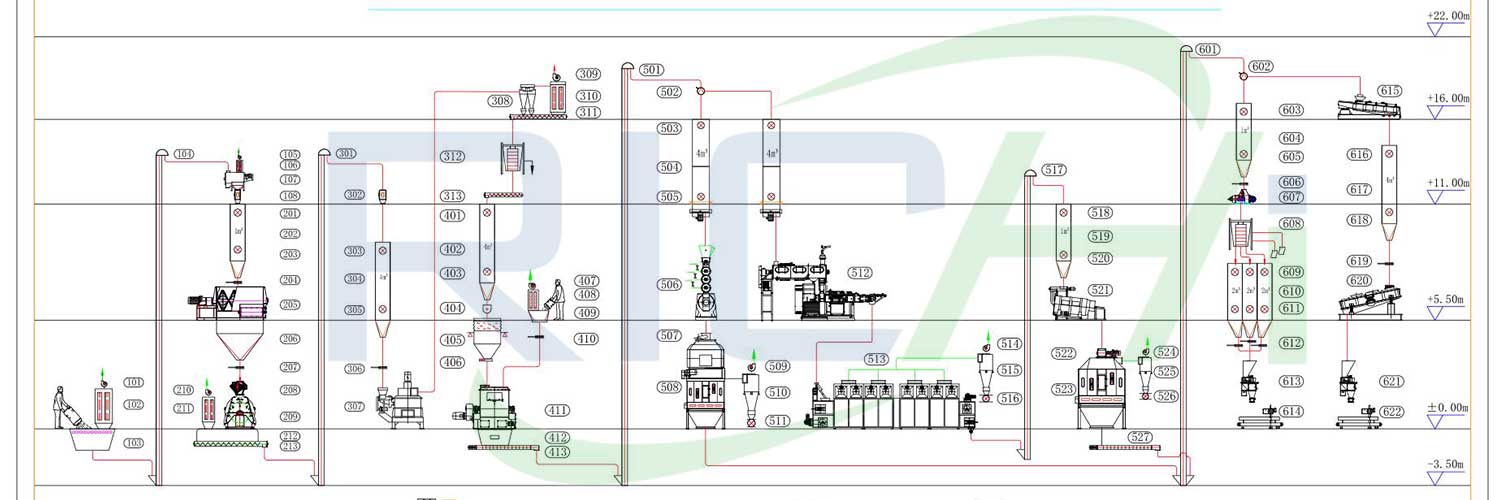

The whole shrimp feed pellet production line consists of four main sections: raw material receiving and first crushing section – first mixing and second crushing section – second mixing, extrusion and drying section – screening, cooling and packing section

The introduction of each section is as follows:

●

Receiving of raw materials and first crushing stage

The removal of impurities and the first crushing of raw materials is a process for processing raw materials that account for a relatively large proportion of shrimp feed pellet formula. After this stage, what is obtained is powdered material of various raw materials.

●

First mixing and second crushing stage

The crushed raw materials are batched and mixed evenly before entering the ultrafine grinder for a second crushing. The second crushing can make the raw materials crushed to a fineness of more than 60 meshes.

●

Second mixing, extrusion and drying process

The crushed raw materials are evenly mixed with premixes, oils, vitamins, etc., and then sent to the shrimp feed extruder. The shrimp feed pellet coming out of the feed extruder are then dried.

●

Screening, cooling and packing section

The qualified shrimp feed pellets are screened out using a rotary grading screen, and then cooled and packed. The feed mill mainly cooperates with farms, so it can be packed according to the needs of the farms.

Some equipments needed for 5 t/h Shrimp feed production line

All the equipment used in the shrimp feed pellet production line was provided by us. Since this feed production project is a turnkey shrimp feed production project, the design of the shrimp feed production line, the construction of the plant, the production of shrimp feed production equipment, the installation of the shrimp feed production line, and after-sales service were all completed by RICHI.

For this shrimp feed production project, we have detailed shrimp feed production line drawings, plant building drawings, production lists, delivery lists, installation drawings and so on.

The following are some of the equipment used in the four main sections of the shrimp feed production line. In addition to these equipment, there are also some auxiliary equipment and accessories such as buffer bins and tees:

| Section | Number | Equipment Name | Model | Quantity |

| Receiving of raw materials and first crushing stage | 1 | Bucket elevator | TDTG40X23 | 2 |

| 2 | Permanent magnet cylinder | TCXT20 | 3 | |

| 3 | Drum primary screening | SCY63 | 1 | |

| 4 | Impeller Feeder | SWLY20*60a | 1 | |

| 5 | Hammer mill | SFSP66*60 | 1 | |

| 6 | Conveyor | TLSS25 | 1 | |

| First mixing and second crushing stage | 1 | Powder cleaning sieve | SCQZ60*50*100 | 2 |

| 2 | Silo | / | 10 | |

| 3 | Rotary distributor | TFPX8 | 1 | |

| 4 | Ingredients Auger | TWLSS20 | 10 | |

| 5 | 0.5 ton weighing bucket | TCD0.5T | 1 | |

| 6 | Mixer | 500kg single shaft paddle mixer | 1 | |

| 7 | Bucket elevator | TDTG40X23 | 1 | |

| 8 | Ultrafine crusher | SWFL130E | 1 | |

| Second mixing, extrusion and drying process | 1 | High Plansifter | SFSJ.100X2 | 1 |

| 2 | Ingredients Auger | TWLSS20 | 2 | |

| 3 | 0.5 ton weighing bucket | TCD0.5T | 1 | |

| 4 | Premix hopper | / | 1 | |

| 5 | Mixer | 500kg single shaft paddle mixer | 1 | |

| 6 | Bucket elevator | TDTG40X23 | 1 | |

| 7 | Twin screw extruder | MY165E | 1 | |

| 8 | Mesh belt dryer | SKGD2000-5ZP | 1 | |

| Screening, cooling and packaging section | 1 | Bucket elevator | TDTG40X23 | 1 |

| 2 | Rotary grading screen | SFJH100*2 | 1 | |

| 3 | Counterflow cooler | SKLN17X17 | 1 | |

| 4 | Automatic packaging equipment | / | 1 | |

Main equipments needed for 5 t/h Shrimp feed production line

High Plansifter

Rotary Grading Screen

Drum Primary Screening

RICHI MACHINERY

Customizable shrimp feed production line in Ecuador

RICHI can customize shrimp feed production equipment and shrimp feed production lines of different capacitys for customers according to the specific needs of each customer, such as the protein content in shrimp feed pellet required for Ecuadorian shrimp farming, the local voltage in Ecuador, the size of the customer’s plant, investment budget, etc.

For feed manufacturers who want to invest in shrimp feed factories in Ecuador, we can use our professional knowledge to provide you with feasible shrimp feed pellet production suggestions and help you quickly enter the shrimp feed industry in Ecuador.

RICHI MACHINERY

Shrimp feed pellet machine can be customized with different capacitys

At present, there are two main shrimp feed pellet production processes in the shrimp feed pellet production field: pelleting process and extrusion process. RICHI can provide shrimp feed pelletizers and shrimp feed extruders with different capacitys to meet the production needs of different shrimp feed pellet processes.

1-10 t/h shrimp feed pellet making machine

1-10 tons per hour shrimp feed pellet machine with three-layer modulator can be equipped with different modulators according to customer needs to ensure the modulation effect of raw materials and produce high-quality sinking shrimp feed pellets.

0.5-12 t/h twin screw feed extruder

The 0.5-12 ton per hour twin screw shrimp feed extruder is the main feed production equipment required in the shrimp feed extrusion process, suitable for the production needs of medium and large feed factories.

1-5 t/h single screw feed extruder

The 1-5 t/h single screw feed extruder can accurately adjust the expansion rate of shrimp feed pellets through the expansion control system in the extruder to obtain full and complete sedimentation and produce high-quality shrimp feed pellets.

0.5-5 t/h Prawn feed production equipment

0.5-5 tons per hour shrimp feed production equipment specially used for producing South American shrimp feed pellets can produce shrimp feed pellets with 100% sinking and high fat and protein content.

This is just part of the capacity and some models of shrimp feed production equipment produced by RICHI. If you have any special output requirements for shrimp feed pellet production, you can contact us at any time. We can customize shrimp feed production equipment with appropriate capacity for you according to your needs.

RICHI MACHINERY

A variety of shrimp feed production solutions to choose from

We have professional design team and technical engineers. All of our shrimp feed production lines are customized and can provide you with a variety of production solutions for you to choose from according to the size of the plant and other conditions.

2 tons per hour Shrimp Feed Production Line

Use pelleting process, equipped with a pellet mill with three-layer conditioner to produce shrimp feed pellets.

1.8-2 t/h Shrimp Feed Pellet Production Line

Using extrusion technology, equipped with single screw extruder, feed production line is needed for medium or small shrimp feed pellet mill.

10 t/h Shrimp Feed Production Line

Using extrusion process, equipped with twin feed screw extruder, suitable for one shrimp feed production line in medium and large shrimp feed factories.

5 t/h shrimp feed & 2 t/h floating fish feed production line

The compound feed production line equipped with shrimp feed pelletizer and feed extruder can produce shrimp feed and floating fish feed at the same time.

RICHI MACHINERY

Why choose us?

professional technique

RICHI always pays attention to the advancement of technology, and cooperates with well-known universities and research institutes to jointly explore the development direction of feed production equipment technology and areas for improvement. Therefore, RICHI has always been a leader in the field of feed production equipment production, leading the development of feed production equipment.

High quality feed production equipment

With 29 years of experience in feed production equipment manufacturing, over 50,000㎡ of modern factory buildings, CE/ISO and other international certifications, and 27 patent certificates, we can provide customers with high-quality shrimp feed pellet production equipment and shrimp feed pellet production lines.

Comprehensive services

For pre-sales service, our engineers will design a suitable fish feed production plan according to the requirements; for in-sales service, our production department will promptly synchronize the relevant progress of the feed pellet machine to customers; for after-sales service, we provide a one-year warranty, accessories support and permanent after-sales service.

RICHI MACHINERY

RICHI serves customers around the world

Founded in 1995, RICHI has been serving Europe, America, Africa, the Middle East, Asia and other regions for nearly 30 years. The feed production equipments and pellet production equipments produced by RICHI are exported to many countries and regions in the world.

As professional feed production equipment manufacturer and pellet production equipment manufacturer, RICHI focuses on the design and manufacture of 1-100 tons per hour feed production projects and 1-50 tons per hour wood pellet production projects, and is committed to creating high-quality feed production projects and pellet production projects for global customers.

No matter which country you are from, as long as you have feed production needs or pellet production needs, you can contact us at any time and communicate with us in detail about your needs and plans.

2000+

client

200+

project

180+

Exporting Countries

24h

24/7 service