Belt Dryer

Professional belt dryer and drying system supplier.

We can provide belt dryers with capacity of 2-12 tons/hour.

RICHI belt dryers are widely used in various fields such as wood, food, chemicals, pharmaceuticals, and pellets.

Belt dryer is a continuous drying equipment. The material to be dried is evenly distributed on the screen. The material is stationary relative to the screen and moves forward with the screen, which effectively reduces the crushing rate. The drying time can be adjusted according to specific requirements.

RICHI belt dryer is designed for high productivity and continuous operation in industrial environments. It has good drying effect and can be used for the process dehydration of various products in agriculture and processing industry.

RICHI MACHINERY

Structural Advantages of RICHI Belt Dryer

With a RICHI poultry feed pellet making machine, you are well prepared for poultry pellets production of all kinds. Everyone shows a balanced mix of performance and agility, speed and precision, always combined with maximum economy.

For example, energy consumption is significantly reduced compared to comparable products. One reason for this is the latest pelletizing systems – they make RICHI poultry feed pellet machines even more powerful, efficient and flexible. Experience with a RICHI poultry pellet making machine how affordable the latest ring die and pelletizing technology can be.

RICHI belt dryer has the following advantages in structure:

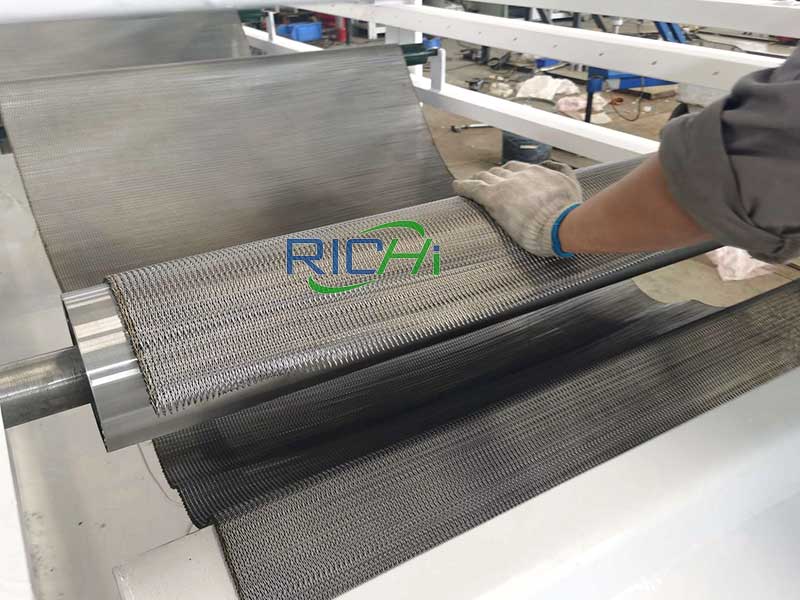

- All mesh belts on the belt dryer are made of PET woven mesh belts, which are acid and alkali resistant and have high air permeability, which can effectively increase the drying efficiency by more than 25%; and can prevent the material from getting stuck or falling on the mesh belt;

- The hot drying air introduced into the belt dryer adopts the method of convection circulation in different directions, so that the material is dried evenly from top to bottom and from left to right, and the moisture error rate can be kept within 2%;

- The high-efficiency steam trap in the heat exchange device can effectively remove air and condensed water from the steam pipe. After the air and condensed water in the steam pipe are removed, the heat exchange function can be improved by 10%;

- The dry hot air is recycled, and the heat exchange efficiency is greatly improved, which can save a lot of steam energy;

- The drying time is set by variable frequency stepless adjustment, which makes it easy to control the moisture content of the product and reach the standard range;

- Adopt swinging distributor, the material is evenly distributed and the moisture is uniform;

- Automatic temperature control device can be selected according to demand. The drying temperature is controlled by microcomputer PID automatic temperature control system, matched with proportional pneumatic control valve. The temperature control is accurate within the positive and negative error of 3℃.

The entire belt dryer is made of stainless steel. The temperature of each area is displayed independently, the speed of the mesh belt is adjustable, a circulating coil is set inside, and it is equipped with a hard-toothed reducer.

RICHI MACHINERY

Applications of Belt Dryer

The belt dryer has a wide range of applications. We have developed belt dryers for different application areas and different product drying requirements in each application area, which can meet the needs of almost all products that need to be dried.

The following are the more common application areas of belt dryers. Of course, in addition to the products in these fields, belt dryers may also be used in other fields. As long as your product has drying requirements, even if it is not in the following fields, you can contact us to obtain detailed information on the belt dryer you need.

Wood Drying Industry

Wood and wood waste are widely used. Whether it is used to produce wood chip fuel pellets or to make furniture, the wood needs to be dried to remove moisture from the wood.

RICHI has been committed to the research of drying wood and its wood waste. The belt dryer developed by it can meet the drying needs of wood chips, wood shavings, sawdust, etc.

Food Drying Industry

Drying is a common method of processing food, which removes moisture from food to achieve long-term storage. Drying can also change the taste of some foods, making them crispier.

RICHI belt dryer can meet the drying needs of different foods, such as vegetables, fruits, dried fruits, coffee beans, spices, etc.

Agricultural Drying

The drying of agricultural products is a very important drying field, which mainly includes the drying of grain and agricultural product waste.

RICHI has been continuously improving the applicability of belt dryers in the agricultural field. The belt dryers it produces have been widely used in the agricultural field, such as drying of cereals, corn, alfalfa, straw, sunflower shells, palm shells etc.

Drying of Extruded Products

As the extrusion process continues to mature, it is not only applied to the food industry, but is also widely used in the production of aquatic feed, pet feed and other fields.

RICHI belt dryer can meet the drying needs of pet feed pellets, aquatic feed pellets, grains, fats, vegetables and other mixed extrudates, and has a good drying effect.

Pellet Drying

All kinds of pellet compressed by molds need to be dried during the production process.

RICHI belt dryer can meet the drying needs of various types of pellets such as biomass fuel pellets, feed pellets, cat litter pellets, organic fertilizer pellets, poultry litter pellets, etc. It can be widely used in feed mills, biomass pellet plants and other pellet production plants.

Drying of Chemical And Pharmaceutical Products

Belt dryers are used in many areas of the chemical industry, such as the pharmaceutical field, cosmetics industry, plastics industry, paper and pulp industry, etc.

RICHI customizes professional belt dryers for the drying of these special products, which can meet the drying requirements of each special product.

Can’t Find Belt Dryer You Want?

Contact Us To Customize For You

RICHI MACHINERY

Products That Can Be Dried By Belt Dryers

01

Pasture

Alfalfa, miscanthus, straw, corn stalks, etc.;

02

Shells of various agricultural products

Sunflower shells, palm shells, coconut shells, peanut shells, cotton shells, etc.;

03

Food

Corn, soybeans, barley, wheat, oats, sweet potatoes, etc.;

04

Dried fruits

Pistachios, almonds, almonds, coffee beans, etc.;

05

Pellets

Feed pellets, wood chip pellets, fuel pellets, aquatic feed pellets, pet feed pellets, cat litter pellets, poultry litter pellets, organic fertilizer pellets, etc.;

06

Fruits

Banana, durian, mango, apple, blueberry, etc.;

07

Meat

Beef, chicken, pork, shrimp, seafood, etc.;

08

Vegetables

Konjac, tomatoes, peppers, mushrooms, onions, potatoes, etc.;

09

Chinese medicine and spices

Star anise, cinnamon, black pepper, ginger, cardamom, tobacco, hemp, etc.;

10

Others

Shredded recycling materials, sewage sludge and digestate, etc.

Can’t Find Belt Dryer You Want?

Contact Us To Customize For You

RICHI MACHINERY

Working Principle of Belt Dryer

Drying is to remove excess moisture from the material. The drying process is a complex physical and chemical process, accompanied by the exchange and transfer of moisture and energy.

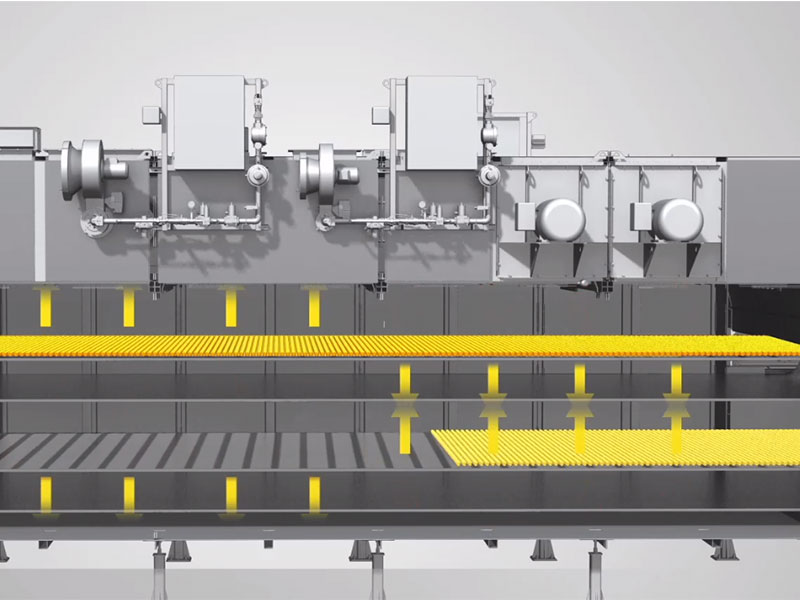

The working process of RICHI belt dryer is mainly divided into the following three steps:

01

During the drying process, the RICHI belt dryer needs to transport the dried material to the adjustable speed mesh belt for even distribution. The hot air flows through the gap between the mesh belt and the material from top to bottom, making each surface of the dried material a heated surface, increasing the contact area between the material and the hot air.

02

The material moves along the transmission belt and the water evaporates gradually, so the material is dried.

03

After drying, the product can be cooled as required;

The main variables that affect the drying effect of materials are the following:

- Operating temperature: Adjust to a higher temperature as possible

- Air humidity: As dry as possible

- Air distribution: Even distribution

- Drying time: Determined according to the original moisture of the material and the moisture after drying

- Product distribution: uniform distribution thickness

RICHI MACHINERY

Advantages of RICHI Belt Dryer

RICHI belt dryer is developed and manufactured by a professional technical team. Compared with traditional air drying and other types of dryers, it has the advantages of large drying area and high drying efficiency. It is suitable for products that need to be dried in various industries.

The Belt Dryer Can Be Customized

Single-layer, double-layer, and multi-layer belt dryers can be customized according to the site area to save the floor space of the factory;

Modular Design

The belt dryer has a modular design that allows for quick on-site installation and is suitable for different performance ranges and applications;

Wide Application Range

Suitable for industrial batch drying of various particles, grains, food, food, forage, wood, etc., and can be produced continuously;

Fully Automatic Control System

Drying temperature and humidity can be selected according to the process requirements of different products to realize the automation of the drying process;

Maintain Material Integrity

The material does not deform, crack or oxidize, and the loss of nutrients is minimal, which can effectively protect the color, aroma, taste and shape of the dried product;

Flexible Production Site

Abandoned sites can be transformed into workshops, and drying business can be started quickly with less investment.

RICHI MACHINERY

Parameters of Belt dryer

The capacity range of RICHI stainless steel belt dryer is sometimes available in 2-12 tons, which can meet the production needs of our customers.

Of course, some customers have special requirements on the output or material of the belt dryer. You can contact us at any time and communicate with our professional engineers to customize a suitable belt dryer.

| No. | NAME | CAPACITY (T/H) | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | |||||

| 1 | Drying machine(Full stainless steel ) | 2~3 | WDWS150-4/2 | 1 | 44.30 | 44.3 |

| 2 | Drying machine(Full stainless steel ) | 3~4 | WDWS200-4/2 | 1 | 49.80 | 49.8 |

| 3 | Drying machine(Full stainless steel ) | 5~7 | WDWS200/5-4 WDWS220/4-4 | 1 | 53.20 | 53.2 |

| 4 | Drying machine(Full stainless steel ) | 8~12 | WDWS220/5-4 | 1 | 71.80 | 71.8 |

Can’t Find Belt Dryer You Want?

Contact Us To Customize For You

RICHI MACHINERY

Our Belt Dryers in Successful Use

Mature technology, high-quality equipment quality, and a full range of service systems make RICHI belt dryers popular with many customers. RICHI belt dryers have been exported to more than 40 countries and regions.

Germany

Beet Pulp Belt Dryer in Germany

Dryer Model: WDWS220/5-4

Capacity: 10 tons per hour

Drying humidity: The humidity of raw materials is 70%, and the humidity of beet pulp after drying is 63%

Russia

Wood Chip Belt Dryer in Russia

Dryer Model: WDWS200/5-4

Capacity: 7 tons per hour

Drying humidity: The humidity of the raw material is 50%, and the humidity of the sawdust after drying is 10%.

Austria

Tree Belt Dryer in Austria

Dryer Model: WDWS220/5-4

Capacity: 12 tons per hour

Drying humidity: The humidity of the raw material is 53%, and the humidity of the dried bark is 37%.

Zealand

Feed Pellet Belt Dryer in New Zealand

Dryer Model: WDWS200/5-4

Capacity: 5 tons per hour

Drying humidity: The moisture content of the feed pellets is 24%, and the moisture content of the feed pellets after drying is 11%

RICHI MACHINERY

How To Choose Belt Dryer

High-quality belt dryers can not only improve the drying efficiency of the product, but also reduce various problems caused by the dryer in the subsequent continuous drying production process.

When users choose a dryer, in addition to the quality of the dryer itself, the more important point is the selection of the belt dryer manufacturer. A good manufacturer can definitely produce high-quality belt dryers, so choosing a belt dryer is actually choosing the belt dryer manufacturer.

Determine if drying your own product is appropriate

First, you need to determine whether the purchased belt dryer is suitable for drying your products and the drying effect, especially for some special products. This requires the belt dryer manufacturer to have equipment and analytical capabilities to test the drying function.

After understanding the products that customers need to dry and the desired effects, qualified belt dryer manufacturers will evaluate the drying products, estimate a series of issues such as the temperature required for drying, drying time, energy consumption during drying, etc., and equip customers with suitable belt dryer models.

Professional belt dryer manufacturer

Investigate the design level and production capacity of the belt dryer manufacturer. Professional belt dryer manufacturers have professional designers who can design belt dryers that meet customer expectations based on the specific needs of customers.

In addition, production capacity is also an important indicator that needs to be examined. You can visit the production workshop and the production equipment in the workshop. At the same time, if conditions permit, you can also visit the project site built by the manufacturer directly.

Reliable after-sales service

Since the belt dryer is large in size and the investment cost is relatively high, the cost recovery period may be relatively longer. Therefore, reliable after-sales service is a must for users.

When using the belt dryer, users may encounter various minor problems such as production problems, spare parts procurement, equipment failure, etc. At this time, if they can contact the manufacturer’s after-sales department in time, the normal operation of the equipment can be guaranteed.

RICHI MACHINERY

Precautions For Using The Belt Dryer

Correct use can not only improve the production efficiency of the belt dryer, but also extend the service life of the belt dryer and maximize the benefits.

Precautions for installation

- The equipment needs to be installed on a horizontal concrete foundation and fixed with anchor bolts;

- Equip the equipment with power cord and control switch according to its power;

- During installation, attention should be paid to the verticality of the machine body and the horizontal direction;

- During installation, the bolts in each part should not be loosened and the main engine compartment door should be tightened;

Adjustment before belt dryer operation

- Confirm that the rotation direction of each circulation fan and the main fan of the hot air furnace is correct;

- Sufficient lubricating oil (grease) needs to be added to the lubrication points;

- Ensure the normal operation of the speed regulating motor. When speed regulation is required, turn the frequency conversion hand wheel of the inverter.

- Check the working condition of temperature controller, humidity controller and other instruments;

- The machine must be cleaned before use to remove debris from the surface of the mesh belt;

Maintenance of the entire belt dryer

- Check the working position of the mesh belt regularly to ensure that it is not displaced, stuck or inverted;

- If abnormal impact, vibration or noise occurs, the machine should be stopped immediately for inspection and repair;

- During operation, the temperature rise of the fan, transmission parts and bearings of the speed change device should be checked regularly. The temperature rise of the motor should not exceed the specified value indicated on the nameplate.

- Check and add lubricating oil (grease) to each lubrication point regularly;

- Regularly check the working conditions of transmission parts and wearing parts, and repair or replace them in time;