In 2023, the world-renowned feed pellet production manufacturer approached us and purchased an aquatic feed pellet production line with annual output of 15,000 tons from us, hoping to open up the Indian aquatic feed market through this aquatic feed production line. RICHI aquatic feed production machine also officially entered the Indian market through this aquatic feed production line.

As the world’s second largest aquaculture country, India has the natural aquaculture environment. Aquaculture is a very important industry in the region, especially in recent years, the aquaculture industry has developed more rapidly.

But for India’s aquaculture industry, an urgent problem that needs to be solved is the supply of high-quality aquatic feed pellet, which is why this well-known feed pellet production manufacturer found us.

The feed pellet production manufacturer has been supplying feed to India and has built feed pellet mill in many countries. After comprehensively considering the market demand for aquatic feed pellet in India, it decided to build an aquatic feed pellet plant in India to meet the local market demand for aquatic feed pellet.

Indian customers found us

In 2023, after the feed manufacturer had a preliminary idea, they contacted us online and consulted us: I want to build an aquatic feed pellet plant in India. Can you send me the price list for aquatic feed production machine?

After understanding the needs of the customer, we arranged for professional sales engineers to communicate with the customer. After field investigations, multiple negotiations, and multiple changes in the design of the aquatic feed pellet production line, the feed manufacturer was convinced that RICHI could help them build the professional aquatic feed pellet mill in India, and finally decided to sign a contract with RICHI for 5 tons per hour aquatic feed production line.

This is not the first time that our feed pellet making machine has been exported to India. We have exported several feed pellet mills and poultry feed pellet production lines to India before, but this is the first time that the complete 5 tons per hour aquatic feed production line has been exported to India. Therefore, we attach great importance to this cooperation, which also helps RICHI open the door to aquatic feed pellet production in India.

RICHI MACHINERY

Overview of 5 t/h aquatic feed production line in India

The aquatic feed pellet plant covers an area of 10,000 square meters and includes aquatic feed making machine. In addition, from the perspective of sustainable development, the aquatic feed processing plant also has systems such as rainwater mobile phones and sewage treatment plants.

Among them, the most important equipment in the aquatic feed pellet plant is the 5 tons per hour aquatic feed production line that built by RICHI, which can produce extruded floating and sinking feed pellet according to customer requirements to meet the needs of shrimp and fish farming. The shrimp farming needs mainly include white tiger shrimp and black tiger shrimp, and the fish farming mainly includes Indian dalli and high-value fish, such as snakehead and sea bass.

The aquatic feed produced by this aquatic feed pellet mill will not only meet the aquaculture needs of India, but also serve customers in neighboring regions such as Bangladesh, Sri Lanka and the Middle East.

Process design of 5 tons per hour aquatic feed production line in India

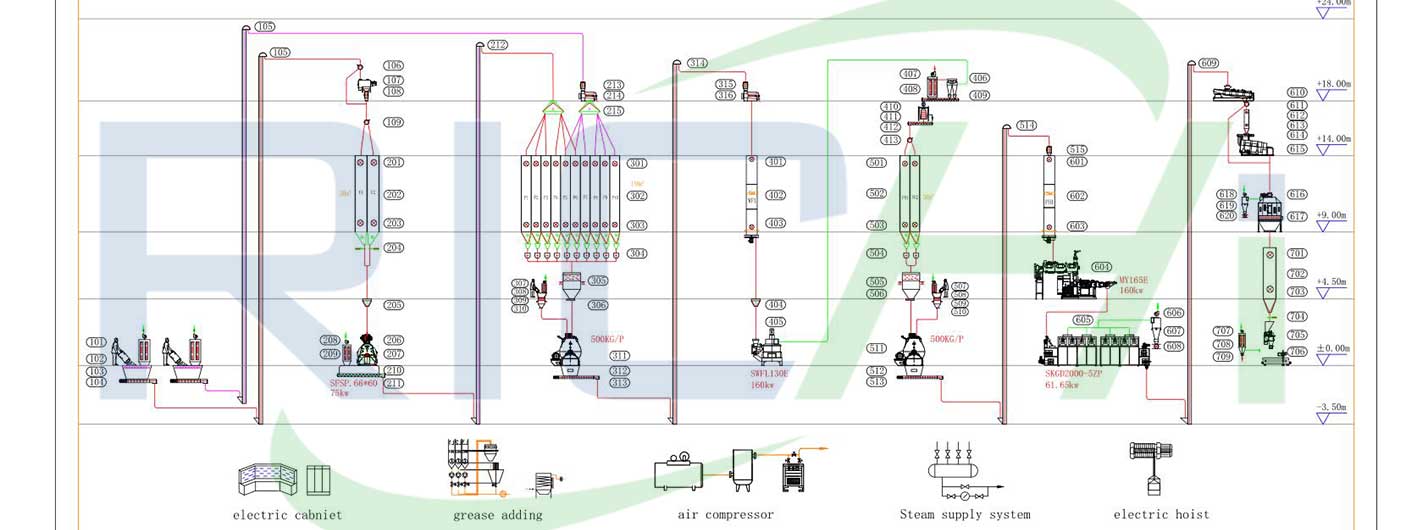

This aquatic feed production line is customized design. The height and layout of the aquatic feed pellet production line are designed according to the customer’s factory. The process of the aquatic feed production line includes: batching after crushing, first mixing, second crushing (using ultra-fine grinder for re-crushing), second mixing, pelleting, extrusion, drying, spraying, cooling, and packing.

This is a composite aquatic feed production line. After comprehensive consideration, the customer decided to equip the pelletizing and extrusion sections with feed pelletizier and feed extruder at the same time.

●

The first crushing and batching section of the 5-ton aquatic feed production line in India

The aquatic feed factory adopts the method of first grinding and then mixing. The materials to be crushed are crushed by a hammer mill, then transported to the mixing bin by an elevator, and then enter the batching scale for batching.

The feed hammer mill adopts the variable frequency impeller feeding device, which can adjust the feeding speed by adjusting the frequency converter, so that the crushing efficiency of the grinder can be improved.

At the same time, the hammer mill is equipped with a negative pressure ventilation system, including a fan and a pulse dust collector, which can help the hammer mill to discharge materials better and increase the capacity of the hammer mill.

●

The first mixing section of the 5-ton aquatic feed production line in India

After the batching is completed, the materials are transported to the mixer and mixed evenly in the mixer.

The material at this time is powdery material, so it is equipped with a dust removal device to prevent dust from escaping, protect the working environment of the aquatic feed production workshop, and the health of the workers in the aquatic feed pellet production workshop.

●

Second crushing section of 5 tons aquatic feed production line in India

Due to the short digestive tracts and unique eating habits of aquatic organisms, such as fish and shrimp, especially shrimp, the production process of aquatic feed requires a relatively high degree of grinding fineness of raw materials.

Therefore, when we designed the aquatic feed pellet production plan, the customer took the initiative to propose the need for secondary crushing. We equipped the customer with an ultra-fine grinder, which has a relatively high crushing fineness, reaching more than 60-80 meshes, which can fully meet the needs of aquatic organisms.

●

Second mixing section of 5 tons aquatic feed production line in India

All materials that need to be added to the feed formula need to be transported to the feed mixer, which has the capacity of 2 tons/batch. In this mixing section, all materials are evenly mixed and then sent to the pelleting room or the extrusion room.

●

Extrusion section of 5 tons aquatic feed production line in India

The mixed materials enter the feed extruder, where they are subjected to high temperature, high pressure, and high humidity, and then squeezed, kneaded, and sheared by the screw to form extruded aquatic feed pellets.

This section is equipped with the twin-screw feed extruder.

●

Pelletizing section of 5 tons aquatic feed production line in India

The customer needs to produce sinking aquatic feed and shrimp feed. The use of feed extruder can also achieve this production goal. However, after comprehensive consideration, the customer decided to equip the feed pelletizer with three-layer modulator.

The feed pellet mill with three-layer modulator can fully meet the production needs of sinking aquatic feed pellet.

●

Drying section of 5-ton aquatic feed production line in India

The aquatic feed pellets coming out of the feed pellet machine and feed extruder have high moisture content, are easy to crush, and are not easy to store and transport, so they need to be dried.

This section is equipped with the belt dryer for customers. The moisture content of the feed pellets after drying in the belt dryer can reach about 13%, making them easy to store and transport.

●

Spraying section of 5-ton aquatic feed production line in India

In order to increase the oil content of feed pellets, we equip customers with vacuum spraying machine that can spray oil onto the surface and inside of feed pellets to meet the energy needs of aquatic organisms to the greatest extent possible.

●

Cooling section of 5-ton aquatic feed production line in India

After the above series of treatments, the temperature of the aquatic feed pellets is relatively high, reaching 80 to 90 degrees, or even more than 100 degrees, so the pellet cooler is needed to quickly cool the temperature of the feed pellets to room temperature.

●

Packing section of 5-ton aquatic feed production line in India

The qualified feed pellets are packaged into 10-50 kg bags through packing scales for easy transportation and sales.

Main equipments needed for 5 t/h Shrimp feed production line

SFSP 66×100 Hammer Mill

The hammer mill developed by RICHI has hammers arranged at a certain angle and evenly distributed. During the production process, the hammers use a forging process, which has high hardness, reduces wear, and can better crush materials.

SWFL128D Ultrafine Grinder

The ultra-fine grinder developed by RICHI specifically for aquatic feed pellet production lines can grind materials to a fineness of 60 to 80 mesh, which can fully meet the production needs of aquatic feed pellet.

SPHS150*2 twin screw extruder

The twin screw feed extruder is specially developed for the production of floating fish feed and can process raw materials with high fat and high moisture content.

SZLH420 feed pellet machine

It is used to produce shrimp feed pelley and sinking aquatic feed pellet, which can meet production needs while saving production costs.

RIHG8000-6 belt dryer

Ruiqi Machinery’s box-type belt dryer uses imported PET woven mesh belt for conveying, with high ventilation efficiency and drying efficiency increased by more than 25%.

Vacuum Spraying Machine

It can spray liquids such as oil into the feed particles, effectively increasing the spraying area of the feed pellets.

RICHI officially entered the Indian market

At present, the aquatic feed pellet production line has been officially put into production, and the aquatic feed produced has entered the market and is very popular in the Indian market.

With this complete aquatic feed pellet production line, RICHI has officially entered the aquatic feed production market in India. Faced with the rapid development of aquaculture in India, the increasing demand for aquatic feed pellet, and the increasing requirements for the quality of aquatic feed pellet, RICHI hopes to have more cooperation with Indian customers.

So if you are interested in the production of aquatic feed pellet such as fish feed production machine, fish feed production line, fish feed pellet mill, etc., you can contact us immediately to get more detailed information, such as product catalog, price list, pictures and videos of aquatic feed production machine, etc.