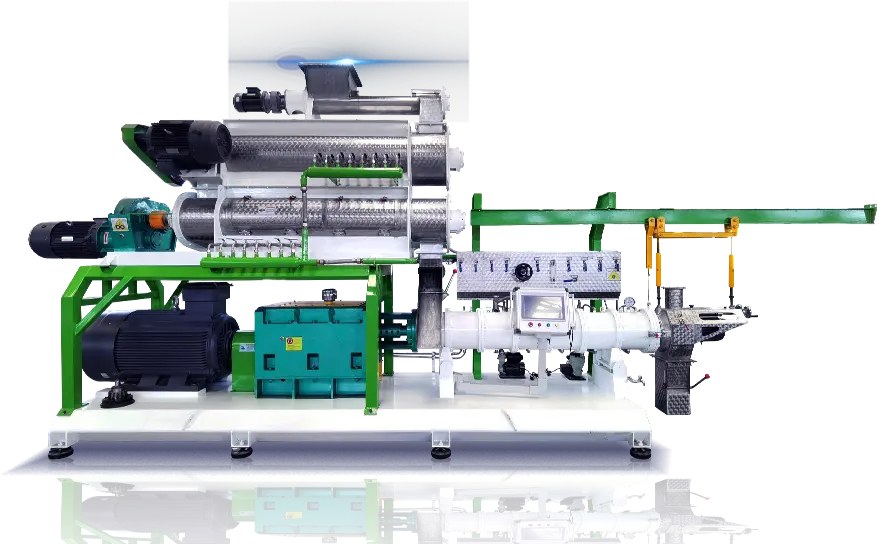

Aqua Feed Extruder

High quality aquatic feed production equipment, can be used to produce high-end sinking and floating aquatic feed pellet, pet food and other extruded feed pellets.

Capacity: 1-12 T/H

The use of extrusion technology to produce fish feed pellets has become the method generally accepted by the feed processing industry. The most important equipment used in the process of extruded fish feed oellet is the fish feed extruder. The international use of twin screw extruders to produce aquatic feed pellet and special feed pellet for aquatic organisms has a history of more than 30 years, and RICHI has also been researching fish feed extruder machine for nearly 30 years.

At present, RICHI Aqua feed extruder machine is widely used in various aquaculture farms and feed processing plants due to its many advantages such as good machine performance, high output and good quality of fish feed pellet produced.

Application of Fish Feed Extruder

RICHI fish feed extruder machine can be used to produce a variety of feed pellets

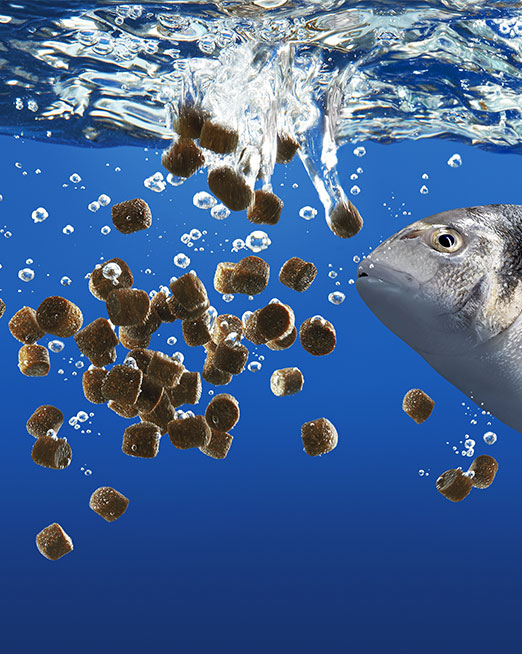

Aqua feed extruder machine is mainly used to produce extruded feed pellets in the extrusion process. Compared with the pelleting process to produce hard fish feed pellets, the feed pellets produced by the aqua feed extruder are puffed feed pellets. And the pelleting process can only produce sinking fish feed pellets, which greatly limits the choice of feed types. The fish feed extruder can be used to produce common floating fish feed pellet, sinking fish feed pellet, slow sinking fish feed pellet, etc., to meet the breeding needs of multi-aquatic fish.

Floating fish feed extruder machine

It can process raw materials with high oil and high moisture content, so that the finished fish feed pellets can meet the growth needs of salmon, trout, sturgeon, etc.

sinking Fish feed extruder machine

Fish feed extruder machine can also be used to produce sinking fish feed pellets, and the produced sinking fish feed pellets can sink to the bottom of the water for a long time without deformation.

Slow sinking fish feed extruder

The parameters of the fish feed extruder can be adjusted to produce slow-sinking fish feed pellets to meet the feeding needs of fish in the middle water layer.

In addition to producing extruded fish feed pellet, RICHI fish feed extruder machine can also be used to produce pet food pellets, shrimp feed pellets, crab feed pellets, and some special types of aquatic organism feed pellets, such as fish bait feed pellets, ornamental fish feed pellets, fry feed pellets, etc.

If you want to know more fish feed extruder parameters and fish feed extruder machine prices, please contact us directly.

fish feed extruder machine price

RICHI can provide fish feed extruders with different prices for you to choose

Reference range of RICHI Aqua feed extruder machine price: 7000-100000 USD

The fish feed extruder machine price is affected by many factors, such as capacity, model, special design of fish feed extruder machine and other factors will affect the price of fish feed extruder, so if you want to know the price list of fish feed extruder you need, you can contact us directly.

Compared with the hard fish feed pellets produced by fish feed pellet mill, there are many advantages of using fish feed extruder machine to produce fish feed. So why fish feed extruder is still not used by all fish feed manufacturers? The main reason is the price.

People always think that fish feed extruder machine is more expensive because when fish feed extruder was first developed, its price was much higher than that of fish feed pelletizer. However, after decades of development, the technology of fish feed extruder is now more mature, and the fish feed extruder produced by RICHI has the very high cost performance. In the subsequent operation of feed pellet mill, it can greatly improve the production efficiency of feed pellets. The fish feed pellets produced by RICHI fish feed extruder are also welcomed by the feed market. So if you want to engage in fish feed production, you can learn more about fish feed extruder from us.

Fish feed extruder in fish feed pellet mill

— Richi Machinery —

For fish feed mills, the very important component is the fish feed production line installed in the feed mill. The reputation of the feed pellets produced by the feed mill directly depends on the quality of the fish feed production line. In a complete fish feed production line, the fish feed extrusion system is an indispensable part, which can directly determine the quality of the finished fish feed pellets.

RICHI has been deeply engaged in the design, production, and manufacturing of fish feed production equipment for decades, and can provide the best design and the best fish feed production equipment for every customer who has fish feed pellet production needs.

RICHI has been deeply engaged in the design, production, and manufacturing of fish feed production equipment for decades, and can provide the best design and the best fish feed production equipment for every customer who has fish feed pellet production needs.

5 t/h fish feed mill in Russia

Process flow:

raw material receiving system – first crushing system – batching system and first mixing system – second crushing system – second mixing system – extrusion system and drying system – packing system

Fish feed mill project Introduction:

The feed pellet mill project is located in Russia. In 2022, this Russian customer found us. After visiting our factory and production workshop, he had technical exchanges with our technical engineers and immediately decided to cooperate with us to build the 5 tons per hour fish feed factory.

Application of fish feed extruder machine:

This fish feed production line is equipped with SPHS150*2 twin screw extruder machine, equipped with vacuum sprayer, belt dryer, ultra-fine grinder and other auxiliary equipment to process some raw materials containing high fat and produce floating fish feed pellets.

3-4 t/h fish feed production line in Vietnam

Process flow:

raw material receiving system – crushing system – mixing system – extrusion system – drying system – packing system

Feed mill project Introduction:

This project is located in Vietnam and has been completed. It is a relatively large fish feed pellet mill in the local area. The feed produced can not only meet the demand for fish feed in the local market, but also be exported to neighboring countries.

Application of fish feed extruder machine:

This feed pellet plant can produce both floating fish feed pellet and sinking fish feed pellet, so we have equipped this feed production line with the special twin screw fish feed extruder, which can produce both floating fish feed and sinking fish feed by replacing the screw of the twin screw extruder.

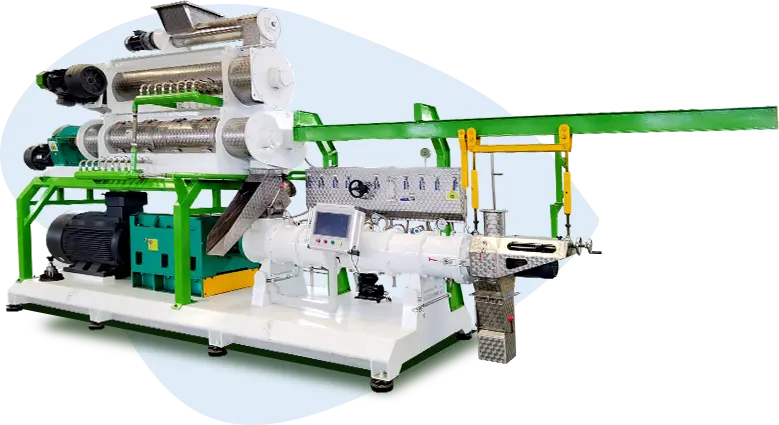

Working Principle of Fish Feed Extruder

Reasonable working process is the guarantee of finished feed pellet quality

RICHI fish feed extruder is reasonably designed, mainly composed of three parts: feeding section, compression section and extrusion section. During the working process, the crushed raw materials are fed into the fish feed extruder from the feeding port. During the conveying process, the materials and water are mixed to form a dough-like object, which is sheared when passing through the barrel. The barrel and the screw rub against each other, the temperature and pressure rise rapidly, the shear force increases, and the material is extruded by the extruder to form fish feed particles of the required length and width.

Feeding system

The silo of the feeding system is uniquely designed to prevent material agglomeration and blockage during the feeding process.

Stainless steel multi-layer modulator

The stainless steel multi-layer modulator can fully ensure the maturation rate of the material and use steam thermal energy instead of mechanical energy, which can reduce power consumption and increase production capacity.

Extrusion chamber

The use of new wear-resistant alloy screw and bimetal expansion chamber sleeve can effectively reduce wear and extend the service life of the fish feed extruder machine.

Molds can be customized

The mold diameter can be customized from φ0.6mm to φ12mm to meet the production needs of various pellet sizes.

Parameters of fish feed extrusion

RICHI can provide various models of fish feed extruders

RICHI technical research on fish feed extruder machine is very mature. After summarizing the production needs of multiple customers, we found that the commonly used fish feed extruder machine models are as follows. However, in the actual design and production process, we will also encounter some users who have special requirements for the capacity, material, etc. of fish feed extruders. So contact us and tell us your specific needs. Our technical staff will provide you fish feed extruder that suits you.

| Model | Main Power(kw) | Dia. of Screw(mm) | Capacity(t/h) | Matching feeder model-power | Matching differential conditioner model-power |

| SPHS120*2 | 75 | 120 | 1~2 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS120*2 (6.6*1.6*4M 6T) | 90 | 120 | 3~4 | WLQ219×1200-1.5kw | DDC400/300/244-11kw |

| SPHS150*2 | 160 | 150 | 4~5 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS 150*2 (8*2*4.3M 8T ) | 200 | 150 | 6~7 | WLQ219-1300-1.5kw | DDC500/300/244-11kw |

| SPHS185*2 | 315 | 185 | 8~10 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

| SPHS185*2 | 355 | 185 | 10~12 | WLQ219-1300-2.2kw | DDC500/300/300-15kw |

Advantages of fish feed extruder

RICHI fish feed extruder has many advantages in producing aquatic feed pellet

Using fish feed extruder machine to produce fish feed pellets is becoming a more and more widely accepted feed production method in the feed production industry. At present, some countries have fully realized the use of extrusion technology to produce fish feed pellets, and most countries are gradually exploring the use of extrusion technology to produce fish feed pellets.

There are several reasons why using the fish feed extruder to produce feed pellets is so popular:

Can process various types of raw materials

Fish feed extruder has a wide adaptability to raw materials and can handle high viscosity, low viscosity, high oil content, high moisture or sticky, oily, very wet raw materials, as well as some raw materials that are easy to slip during the processing.

The finished pellets have good appearance and high uniformity

Due to the diversity of fish feed formulas, the uniformity of the material is very important. The fish feed pellets produced by the fish feed extruder can achieve a very good homogeneous state, and the surface is smooth and the pellets are highly uniform during the extrusion process.

Fish feed pellets have good ripening effect

The starch maturity in fish feed pellets can reach over 95%, which enables the processed aquatic feed to remain stable in water, retain nutritional value, and be easily digested and absorbed.

Can be used to produce a variety of feed pellets

In addition to producing fish feed pellets, it can also be used to process micro-particle aquatic feed and high-oil formula, high-moisture, high-adhesive products and multi-color, sandwich and special-shaped products.

Fish feed extruder is easy to operate

The spindle speed can be adjusted according to the needs of the processed products. Due to the self-cleaning feature, cleaning is very convenient and there is no need to disassemble the equipment after each processing.

Lower maintenance and production costs

RICHI fish feed extruder has good operating stability, so in the process of feed processing, it has less startup cost, less water and gas waste, less labor cost, high heat transfer efficiency, high finished product rate and high electricity output index.

What we can offer you

High-quality fish feed extruder can produce high-quality extruded feed pellets

Fish feed production line design

RICHI can provide the complete set of design for fish feed pellet mill, fish feed production line and fish feed making machine, including the layout of fish feed pellet mill, process flow of fish feed production line, design of fish feed production equipment and all drawings required during installation.

With thirty years of industry experience, we can build your own fish feed pellet mill for you.

Complete set of fish feed production equipment

Two modern fish feed production equipment factories, more than 30,000 square meters of production workshops, and modern production equipment can ensure the quality of each fish feed production equipment and ensure that each project can be delivered on time.

Worry-free service

Systematic service process, from preliminary communication, to the production of fish feed production equipment, to the delivery of equipment, the installation of fish feed production projects, after-sales service, etc., we have professional personnel responsible for each link, so if you have any questions, you can always find our relevant professional staff.