3-5 t/h fish feed plant

Customized 3-5 tons per hour fish feed factory turnkey project for sale, including fish feed factory process design, fish feed production plan design, and a full set of fish feed production equipment.

Why build the 3-5 t/h fish feed plant

In recent years, as people’s demand for aquatic products such as fish and shrimp has increased, wild fishing can no longer meet human needs, so the aquaculture industry has developed rapidly, and accordingly, the requirements for aquaculture feed have also been increasing.

At present, professional aquaculture farms no longer use powdered or single raw materials, such as soybean meal, fish meal, etc. to feed aquatic organisms, but use nutrient-rich aquatic feed pellets containing a variety of raw materials to feed fish, shrimp and other aquatic organisms, so as to maximize profits. Therefore, the production of aquatic feed pellet now occupies a very important position in the feed pellet production industry.

Many fish and shrimp farms and investors have begun to invest in the fish feed pellet production and shrimp feed pellet production industries and have started to build fish feed plants. The 3-5 tons per hour fish feed plant and shrimp feed plant are favored by investors because of their moderate output, low investment cost, fast construction and short capital recovery period.

As the professional feed making machine manufacturer, RICHI has been committed to building 3-5 tons per hour fish feed plants for customers in need. It has accumulated a lot of mature experience in the construction of fish feed plants and can meet the various needs of customers in the process of building fish feed plants.

3-5 t/h fish feed plant classification

The 3-5 tons per hour fish feed plant we usually refer to is a relatively general concept. It is a general term for all 3-5 tons per hour fish feed plant and is also a relatively common term. However, when customers are actually building a 3-5 tons per hour fish feed plant, they will consider the local demand for feed pellets, their own investment budget, production needs after the feed factory is built, and other comprehensive considerations to build the 3-5 tons per hour fish feed plant that meets their own production needs.

According to the buoyancy and sinking properties of fish feed pellets in water, the following types of 3-5 t/h fish feed plant can be built:

3-5 t/h floating fish feed plant

It is mainly used to produce floating fish feed pellet, which can meet the feeding needs of tilapia, trout, eel, catfish, ornamental fish and other fish on the water surface.

The production of floating fish feed pellet is also a development trend in the current aquatic feed pellet production. The more advanced extrusion technology is used to produce fish feed pellets with high fat content, which can be suspended in water for a longer time.

3-5 t/h sinking fish feed plant

It is mainly used to produce sinking feed to meet the feeding needs of various aquatic organisms such as sturgeon, perch and shrimp.

Conventional sinking fish feed usually use pelleting technology to produce sinking feed pellet. However, with the development of feed production technology, fish feed plants are beginning to use extrusion technology to produce sinking fish feed, which can make up for the shortcomings of using pelleting technology to produce sinking feed pellet.

3-5 t/h slow sinking fish feed plant

It is mainly used to produce slow-sinking feed pellets that can meet the feeding needs of fish in the middle water layer.

In addition to feed pellets that completely float on the water surface and feed pellets that completely sink under the water, there is currently a large demand for slow-sinking fish feed plants on the market, so some investors will also build the 3-5 tons per hour slow sinking fish feed plant to produce fish feed pellets to meet market demand.

In addition to 3-5 tons per hour floating fish feed plants, 3-5 tons per hour sinking fish feed plants, and 3-5 tons per hour slow sinking fish feed plants, some farms or fish feed plant investors will also build some special fish feed pellet production plants for large-scale breeding of fish, such as 3-5 tons per hour trout feed plants, 3-5 tons per hour sturgeon feed plants, 3-5 tons per hour tilapia feed plants, 3-5 tons per hour ornamental fish feed plants, 3-5 tons per hour shrimp feed plants, etc. In addition to this single feed pellet plant, we can also build 3-5 tons per hour compound feed plants that can produce multiple feed pellet at the same time for customers, such as 3-5 tons per hour fish feed and shrimp feed plants, 3-5 tons per hour fish feed and poultry feed production plants, 3-5 tons per hour shrimp feed pellet and poultry feed plants, etc.

3-5 tons per hour fish feed and shrimp feed plants

3-5 tons per hour fish feed and poultry feed production plants

3-5 tons per hour shrimp feed pellet and poultry feed plants

3-5 t/h trout feed plants

3-5 t/h sturgeon feed plants

3-5 t/h tilapia feed plants

3-5 t/h ornamental fish feed plants

3-5 t/h shrimp feed plants

3-5 t/h pet feed plants

Can’t Find Fish Feed Plant You Want?

Contact Us To Customize For You

What 3-5 t/h fish feed plants have we built?

In the past 30 years of feed mill project construction, RICHI has built multiple feed plants and pellet production plants in more than 120 countries around the world. As for 3-5 ton per hour fish feed plants, the following feed pellet production projects can be used as reference:

5 t/h sinking fish feed plant in Uzbekistan

Capacity

5 t/h

Country

Uzbekistan

The feed plant is mainly used to produce sinking fish feed, and is currently considering investing in the production of poultry feed and livestock feed.

5 t/h floating fish feed plant in Russia

Capacity

5 t/h

Country

Russia

It is mainly used to produce fish feed pellet, using relatively advanced extrusion technology to produce high-end aquatic feed pellet.

3 t/h floating fish feed plant in Indonesia

Capacity

3 t/h

Country

Indonesia

It is mainly used to produce floating fish feed pellets and equipped with pelletizer to produce small fish feed pellet.

3-5 t/h fish feed and shrimp feed plant in Angola

Capacity

3-5 t/h

Country

Angola

Use pelleting technology to produce fish feed pellet and shrimp feed pellets, equipped with the pellet mill with a three-layer conditioner for feed.

5 t/h sinking fish feed and poultry feed palnt in india

Capacity

5 t/h

Country

India

It can be used to produce fish feed pellets and poultry feed to maximize the benefits of feed mills.

5 t/h pet feed palnt in China

Capacity

5 t/h

Country

Chinaa

Used to produce high-end pet food pellets in various shapes and flavors.

The composition of 3-5 t/h fish feed plant

If you want to build a 3-5 tons per hour fish feed plant, you need to consider many factors, such as the plant land of the 3-5 tons per hour fish feed plant, the office building construction of the 3-5 tons per hour fish feed plant, the process design and factory layout of the 3-5 tons per hour fish feed plant, etc. But for a 3-5 tons per hour fish feed plant, the most important thing is a complete set of fish feed production equipment that needs to be used in the fish feed plant.

A complete fish feed production line can realize automation and continuous operation from the receipt of raw materials to the packaging of finished pellets, thus improving the production efficiency of fish feed pellets.

With many years of experience in fish feed factory construction, RICHI has currently designed hundreds of 3-5 tons per hour fish feed production line solutions for customers, and each solution will ultimately fully satisfy the customer.

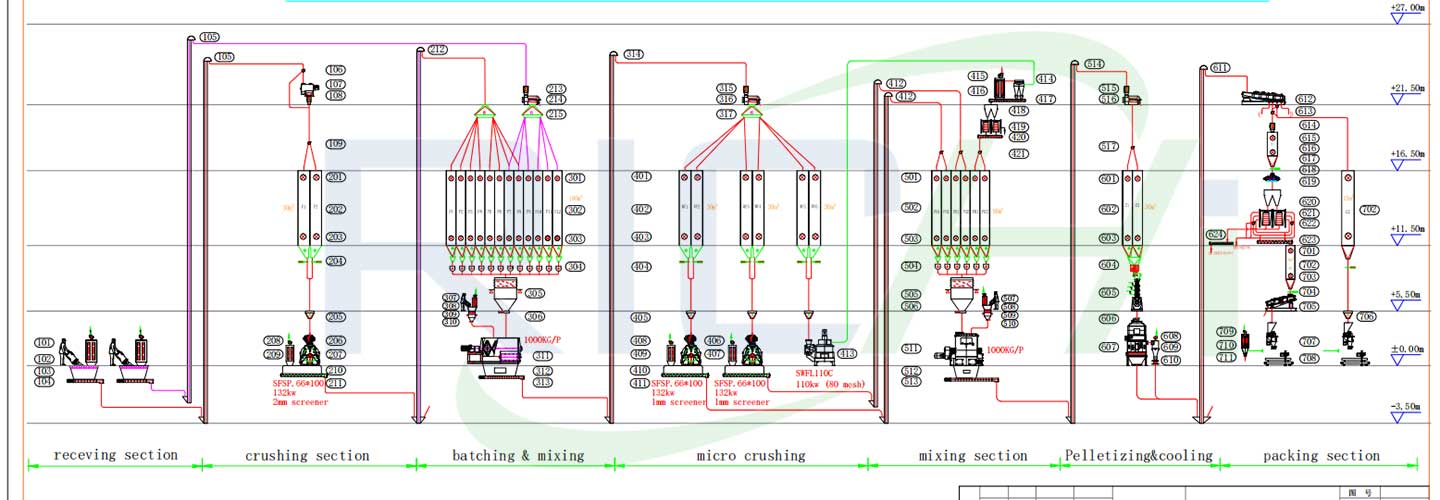

The following is a typical 5 t/h fish feed production line production process designed by us:

●

Receipt of raw materials

There are dozens of raw materials used to produce fish feed pellets and shrimp feed pellets, such as barley, soybean meal, fish meal, etc. Each customer has his own feed formula, so after the raw materials are purchased, they must first be roughly cleaned and classified before being put into the hopper.

●

Crushing of raw materials

For some granular raw materials such as barley, wheat, soybean meal, etc., they need to be crushed before extrusion or granulation. The machine is equipped with SFSP66*60 crusher.

●

Automatic batching and mixing

The automatic batching system is equipped with a silo, which can automatically batch ingredients according to the proportion of raw materials in the feed formula.

●

Second crush

Due to the special feeding needs of aquatic organisms, especially the short digestive tract of shrimps, a second crushing will be performed when producing fish feed pellet or shrimp feed pellets. The second crushing can crush the raw materials to a fineness of more than 80 meshes. The SWFL130E ultra-fine grinder is equipped.

●

Second Mix

The main purpose of the second mixing is to fully mix the raw materials again based on the first mixing, so that the finished particles have balanced nutrition and uniform color.

●

Extrusion and drying

The solution is designed to use extrusion technology to produce feed pellets, which can produce both floating fish feed pellets and sinking feed pellets. The feed needs to be dried after coming out of the extruder.

●

Packing Section

According to customer needs, the produced fish feed pellets can be packaged into bagged feed pellets with a fixed weight, such as 10 kg per bag.

Features of the 5 t/hour fish feed production line

Customizable pellet size and shape, such as 1mm shrimp feed pellets, 2mm fish feed pellets, etc., to meet the feeding needs of different fish and shrimp.

Equipped with a post-spraying system, the oil content of feed pellets can be increased to meet the needs of most fish feed pellets for high oil content.

Equipped with ultra-fine pulverizer, the pulverization fineness is relatively high, which can effectively improve the quality of fish feed and shrimp feed.

The automatic batching system can improve efficiency while also increasing the precision requirements of raw materials in feed formulas.

The entire fish feed production line can work continuously and efficiently, achieving the goal of factory-scale feed pellet production.

The feed production line is reasonably designed, and each production section can be increased or reduced according to customer needs.

Main equipment used in 5 t/h feed production line

A complete feed production line requires many feed production equipment, such as grinders, mixers, extruders, belt dryer and other main equipment, as well as many auxiliary equipment, such as conveyors, silos, cleaning equipment and so on.

RICHI can provide all feed production equipment, and all of these equipment are produced by ourselves. With a production workshop of more than 30,000 square meters, modern production equipment and professional workshop staff, we can ensure the quality of each feed production equipment.

Our factory welcomes every customer to visit and tour at any time, and also welcomes every customer to come to our company and discuss your ideas with us.

SFSP66*60 Hammer Mill

Ultrafine Grinder

Feed Mixer

Twin screw extruder

SKLN17X17 counter-flow cooler

Spraying Equipment

Belt Dryer

Rotary Screener

Other design solutions for 3-5 t/h fish feed plants

— Richi Machinery —

The design of the 5 tons per hour fish feed production line above is one of our more typical designs. However, our designs are not static, but change at any time according to the needs of each customer, including each section in the fish feed production line, which can be added or reduced.

Therefore, in the process of communicating with customers, we first need to know the customer’s existing needs, and then introduce to the customer some of the fish feed production line design solutions we have made, and then customize a unique fish feed production line design solution for the customer based on his specific needs.

The following are the design plans for two other 3-5 ton feed production lines. If you want to know more about the design plans of feed production lines, please contact us directly and we will send you detailed information on the fish feed production line design plans.

Design of 5 tons per hour fish feed production line

This is a feed pellet production design that uses pelleting extrusion to produce sinking fish feed pellets. It is mainly used to produce sinking fish feed pellets and shrimp feed pellets. It can also be used to produce poultry feed pellets and livestock feed pellets by changing the formula.

3-5 tons per hour shrimp feed production line design

This is a 3-5 ton shrimp feed pellet production line design, equipped with the shrimp feed pelletizing machine with three-layer modulator dedicated to shrimp feed pellet production.

3-5 tons per hour fish feed plant business plan

Years of experience in building fish feed palnts tells us that before building a fish feed palnt, we must fully consider the factory layout and process design of the fish feed palnt, and have an overall plan for the entire fish feed palnt. Only in this way can we plan and efficiently and orderly build a 3-5 tons per hour fish feed palnt, so as to realize capital recovery as soon as possible.

This is just a relatively large aspect that needs to be considered when building a fish feed palnt. As for some details and precautions that need to be considered when building a fish feed palnt, there are a lot of content, and different fish feed production line business plans need to be formulated for different customers. So if you need a more detailed business plan that meets your fish feed pellet production needs, contact us directly and we can formulate it for you.

ABOUT RICHI MACHINERY

As the leading manufacturer of feed production equipment, RICHI provides high-quality feed manufacturing equipment and professional services for agriculture and aquaculture. Since its establishment in 1995, RICHI has continuously updated its feed production equipment to keep pace with the times. With advanced feed pellet production equipment processing technology, exquisite process technology, and strict inspection and testing systems, it strives to provide customers with excellent products.

We can provide customers with 1-100 ton feed mill turnkey projects and 1-50 ton fish feed mill turnkey projects, including the design of feed mill layout, the manufacture of complete set of feed production equipment, the installation of feed production equipment, and the training of workshop personnel, etc. Choosing a good partner can help you start the production of aquatic feed pellets more smoothly.