10 t/h fish feed factory

Customized 10 tons per hour fish feed factory turnkey project for sale, including fish feed factory process design, fish feed production plan design, and a full set of fish feed production equipment.

The development prospects of 10 t/h fish feed factory

With the rapid development of breeding industry, aquaculture industry has certain requirements on the output and quality of fish feed pellets. In many countries and regions, the market of fish feed pellets has been in short supply, or the quality of fish feed pellets cannot meet the needs of farms. Therefore, in recent years, when investing in fish feed factories, investors are no longer satisfied with small-scale fish feed factories such as 1 t/h fish feed factories and 2 t/h fish feed factories. Instead, they are more inclined to large-scale, automated fish feed factories. Therefore, 10 t/h fish feed factories are popular with many investors.

At present, many regions have begun to build some medium-sized or large feed pellet mills, including 10 t/h fish feed factory. As the professional feed pellet making machine manufacturer, RICHI has built fish feed factorys for many customers and has accumulated rich and mature experience. It can provide investors with practical feed pellet mill construction advice and reliable fish feed production equipment.

The 10 t/h fish feed factory is suitable for large-scale farms and investors who intend to invest in the feed production industry. Many well-known feed producers will also choose our 10 tons per hour fish feed factory planning when making investment plans for a certain country or region.

We can follow the trend of modern design, continuously innovate and develop new processes based on factors such as customers’ raw materials, fish feed factory area, investment budget, etc., and tailor a scientific and reasonable process layout of a 10 tons per hour fish feed factory for customers, and provide all feed production equipment used in a 10 tons per hour fish feed factory.

10 t/h fish feed factory classification

10 t/h fish feed factory is a more common term, but in the actual construction process of the fish feed plant, according to the specific needs of each customer, we will build 10 tons per hour trout feed pellet mill, 10 tons per hour sturgeon feed pellet mill, 10 tons per hour floating fish feed factory, 10 tons per hour sinking fish feed factory, 10 tons per hour slow sinking fish feed factory, etc.

In addition to 10 tons per hour fish feed factory, as the professional feed production equipment manufacturer, we can also undertake to build 10 tons per hour shrimp feed pellet mill, 10 tons per hour pet feed pellet mill, 10 tons per hour poultry feed pellet mill, 10 tons per hour livestock feed pellet mill, as well as 10 tons per hour fish and shrimp feed pellet mill, 10 tons per hour fish and poultry compound feed pellet mill, 10 tons per hour shrimp and poultry feed pellet mill plant, etc.

10 t/h shrimp feed factory

Shrimp feed pellets can be produced using common pelletizing technology, and can also be produced using the more advanced extrusion technology.

10 t/h pet feed factory

Pet food pellets of various shapes and sizes can be produced to improve the quality of pet food pellets and meet the demand for pet food pellets in the pet market.

10 t/h poultry feed pellet mill

Turnkey poultry feed pellet mill, capable of producing poultry feed pellets of 2-12mm to meet the feeding needs of chickens, ducks, geese, etc., as well as smaller sized crumbles.

10 t/h livestock feed factory

The t/h livestock feed factory can produce pig feed pellets, cattle feed pellets, cow feed pellets, sheep feed pellets, rabbit feed pellets, etc. at the same time to meet the market demand.

10 t/h fish feed and poultry feed factory

We can undertake to build compound feed factories, equipped with feed pelletizers and extruders, to produce fish feed and poultry feed pellets, thus improving the efficiency of fish feed factories.

10 t/h fish feed and shrimp feed factory

That is what we often call an aquatic feed factory, which can produce floating fish feed pellets, sinking feed pellets, etc. of different sizes to meet the feeding needs of aquatic organisms.

Can’t Find Fish Feed Factory You Want?

Contact Us To Customize For You

What 10 t/h fish feed factory projects have we built?

RICHI combines theoretical research results with practical construction and has built more than 100 large-scale feed pellet mill projects at home and abroad. Among them, the 10 tons per hour feed pellet mill project is a very important type of feed mill project we have built.

10 t/h fish feed factory in Vietnam

Capacity

10 t/h

Country

Vietnam

In cooperation with a well-known feed pellet producer, the fish feed factory was built in Vietnam that can produce both sinking feed pellets and shrimp feed pellets.

10 t/h pet feed factory in China

Capacity

10 t/h

Country

China

We are building the pet feed factory project in Hebei Province, China. The feed factory is currently under construction and will soon be put into production.

10 t/h fish feed and poultry feed factory in Iran

Capacity

10 t/h

Country

Iran

This feed mill can produce fish feed pellets, shrimp feed pellets, poultry feed pellets, etc. at the same time, and it is a compound feed mill.

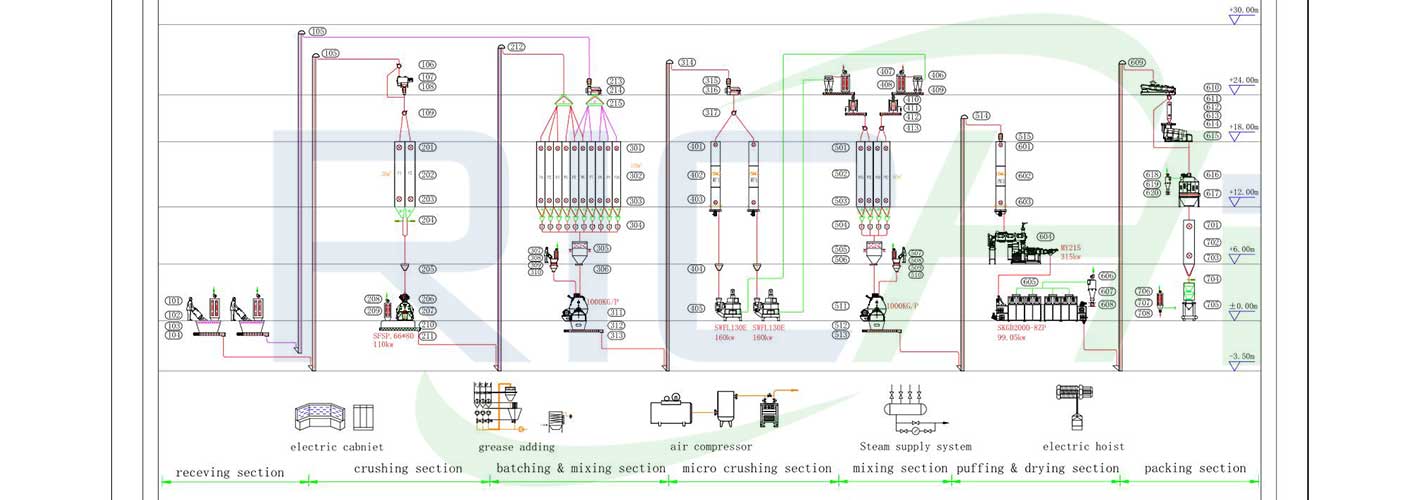

10 t/h fish feed factory process flow

The construction of a 10 tons per hour fish feed factory is a complicated task, including the layout of the fish feed factory, the selection of fish feed factory production equipment, the site selection of the fish feed factory, etc. Among them, the fish feed factory production equipment is the very important part of the fish feed factory. The complete 10 tons per hour fish feed production line used in the 10 tons per hour fish feed factory is the guarantee for the fish feed factory to produce high-end fish feed pellets.

RICHI can provide the layout design of fish feed factory, the design of fish feed production line and all feed production equipment used in the fish feed production line.

The complete 10 tons per hour fish feed production line includes six main sections: raw material receiving, raw material crushing, ingredient mixing, extrusion, liquid spraying, and finished fish feed pellet packing system. At the same time, the entire 10 tons per hour fish feed factory is also equipped with a dust removal system to ensure the production environment of the fish feed factory and the health of workers.

The following is a typical 10 t/h fish feed production line production process designed by us:

●

Receipt of raw materials

The 10 t/h fish feed factory is usually equipped with a silo system. Grain raw materials are sent into the silo and then sent to the workshop by the conveying equipment at the bottom of the silo; powdered raw materials are directly put into the discharge port and then enter the batching silo.

In the process of receiving raw materials, conveying equipment, round primary screening machine, powder cleaning screen, permanent magnetic cylinder, etc. are needed.

●

Crushing of raw materials

Granular raw materials, such as barley and wheat, need to be crushed before extrusion granulation. According to the number of crushing times, it can be divided into the first crushing process and the second crushing process. In order to ensure the quality of the finished feed pellets, the 10 t/h feed pellet mill usually performs two crushing processes.

Because the first crushing process uses the hammer mill, although the equipment investment is small, the crushed pellet size is uneven and the crushing fineness is not enough, so usually an ultra-fine grinder or hammer mill is used for re-crushing to make the material fully crushed and the crushing particle size is basically consistent.

●

Ingredients and Mixing

The batching and mixing process is the key step to ensure the fish feed formula and the quality of fish feed pellets. It is also the most automated system in a 10 tons per hour fish feed factory.

The batching and mixing process includes batching silos, batching scales, mixers, conveying equipment, etc. The core equipment in the entire process is the batching scale and feed mixer. In order to improve the batching accuracy, a microscale can be used to control various trace elements. At the same time, for some special materials in the feed formula, such as premixes, a full stainless steel batching scale can be equipped to ensure the quality of the finished fish feed pellets.

In addition, the liquid adding system is equipped with a separate ingredient scale for weighing to ensure its accuracy.

●

Extrusion

The extrusion system is the largest investment system in the 10 tons per hour fish feed factory, which is mainly composed of feeders, modulators, twin screw feed extruders, ovens, and conveying equipment. The twin screw extruder used is the SPHS185*2 twin screw extruder we equipped for the 10 tons per hour fish feed factory, which has a high feed conversion rate.

The raw materials undergo high temperature and high pressure treatment, starch gelatinization, protein denaturation, etc. during the extrusion process. The extruded fish feed pellet formed can effectively prevent digestive tract diseases of aquatic organisms and increase the digestibility of aquatic organisms by 10%-35%.

●

Liquid spraying

With the rapid development of aquaculture, people pay more and more attention to the quality of aquatic feed pellets. At present, most of the aquatic feed pellets on the market are finished feed pellets after heat processing, that is, modulation, granulation or puffing. Such feed pellets have certain advantages, but also have their disadvantages. That is, after high temperature and high pressure treatment, many heat-sensitive nutritional factors (such as vitamins, enzyme preparations, bovine bacteria, etc.) are seriously damaged.

In order to solve these problems, after a lot of experiments, RICHI experts designed the liquid post-spraying technology, that is, these heat-sensitive raw materials are placed in the feed in the form of liquid after extrusion or granulation. At the same time, liquid spraying can also spray oil into fish feed particles, thereby increasing the oil content of feed pellets.

RICHI provides vacuum spraying equipment and drum spraying equipment for 10 tons per hour fish feed factories. Customers can choose according to their budget and actual needs.

●

Finished fish feed pellet packing system

There are two ways to collect the processed fish feed pellets. One is to pack them directly, usually into 10kg-50kg bags of fish feed pellets. Of course, they can also be packed according to customer needs. In addition, they can also be bulk packed, especially for countries such as Europe and the United States, where transportation is relatively developed, and fish feed pellet bulk trucks can be used directly for bulk packing and transportation.

We equip fish feed factory with automatic packing systems for 10 tons per hour.

Main equipment used in 10 t/h feed production line

The integrity of the design of the 10 tons per hour fish feed production line can ensure the efficiency of fish feed pellet production, and the quality of the equipment used in the fish feed production line is the guarantee of the quality of the finished fish feed pellets.

All the equipment used in the 10 tons per hour fish feed production line are manufactured by RICHI in its own production workshop, mainly including the following equipment: SFSP66*80 Hammer Mill,Ultrafine Grinder,Feed Mixer,Twin screw extruder,counter-flow cooler,Spraying Equipment,Belt Dryer,Rotary Screener.

SFSP66*80 Hammer Mill

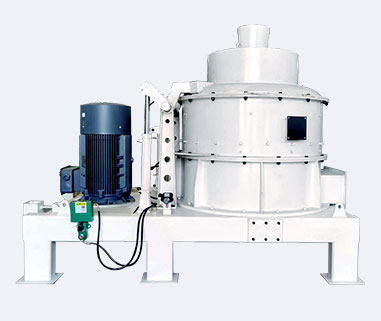

Ultrafine Grinder

Feed Mixer

Twin screw extruder

counter-flow cooler

Spraying Equipment

Belt Dryer

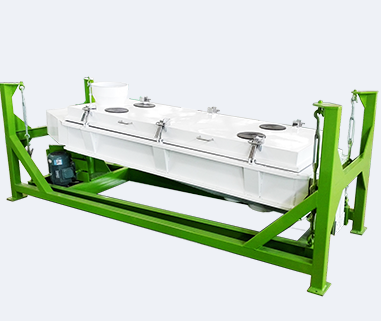

Rotary Screener

How to start building a 10 t/h fish feed factory

If you want to build a 10 tons per hour fish feed factory, you need to have a reasonable step. Following the planning process can ensure that the fish feed factory is built quickly and efficiently.

- Feasibility study: Conduct market research locally, understand local needs and surrounding development needs, and conduct a feasibility study on the fish feed factory project.

- Factory selection: Based on the feasibility study and in accordance with the local construction application process, the fish feed factory project was approved and established, and at the same time, it was connected to public facilities and resources such as water and electricity.

- Determine the fish feed production process and fish feed production equipment: Find the right fish feed making machine manufacturer and determine the design of the fish feed production line that meets the production needs of the factory.

- Determine supporting facilities: In addition to the fish feed production equipment, the building land required for production, office, living, etc. must also be calculated.

- Overall planning and design: According to the fish feed production design and supporting design, the overall design of the fish feed factory is carried out, and sufficient space is reserved for each part.

Considerations in designing the 10 t/h fish feed factory

When designing fish feed factory, you need to consider multiple aspects, such as the site selection of the fish feed factory; the layout of the raw material warehouse, production workshop, finished product warehouse, office building, etc. in the fish feed factory; the area planning of the fish feed factory, etc.

With nearly 30 years of experience in factory construction and turnkey feed factory construction experience, RICHI can give specific and detailed suggestions to each customer when designing a 10 tons per hour fish feed factory.

1. The first thing is the choice of feed factory site

The selection of the feed factory site must comply with local policies and guidelines. Factory land, living land, sewage discharge sites, etc. should be considered and planned in a unified manner at the same time.

The selected feed factory site should have reliable low-quality conditions, and the fish feed factory should not be built on quicksand, silt, or landslide fault layers. At the same time, there should be convenient transportation conditions near the factory, such as roads, railways, and waterways.

2. The second is the principles that should be followed when designing the 10 t/h fish feed factory

The layout of a 10 tons per hour fish feed factory should be based on production, safety, sanitation and other requirements and arrange the buildings, open-air yards, transportation routes, pipelines, greening and beautification facilities within the feed factory area according to local conditions.

Generally speaking, the production workshop of fish feed pellets should be located in the center of the feed factory, and other workshops, office buildings, public facilities, etc. can be arranged around the main workshop.

3. Planning and design of the fish feed pellet section in the feed factory

The production part of the 10 t/h fish feed factory includes: raw material warehouse, boiler room, air compressor room, main production workshop, including crushing, mixing, extrusion, drying, etc., finished product warehouse, including packing, transportation, etc.

Reasonably plan the floor area of each part for location design. For example, the design of the raw material warehouse takes into account the complexity and diversity of the raw materials, so space must be reserved. The finished product warehouse is generally located at the exit of the feed factory for easy transportation.

ABOUT RICHI MACHINERY

As the leading manufacturer of feed production equipment, RICHI provides high-quality feed manufacturing equipment and professional services for agriculture and aquaculture. Since its establishment in 1995, RICHI has continuously updated its feed production equipment to keep pace with the times. With advanced feed pellet production equipment processing technology, exquisite process technology, and strict inspection and testing systems, it strives to provide customers with excellent products.

We can provide customers with 1-100 ton feed mill turnkey projects and 1-50 ton fish feed mill turnkey projects, including the design of feed mill layout, the manufacture of complete set of feed production equipment, the installation of feed production equipment, and the training of workshop personnel, etc. Choosing a good partner can help you start the production of aquatic feed pellets more smoothly.