Choosing Aquatic Feed Making Machine

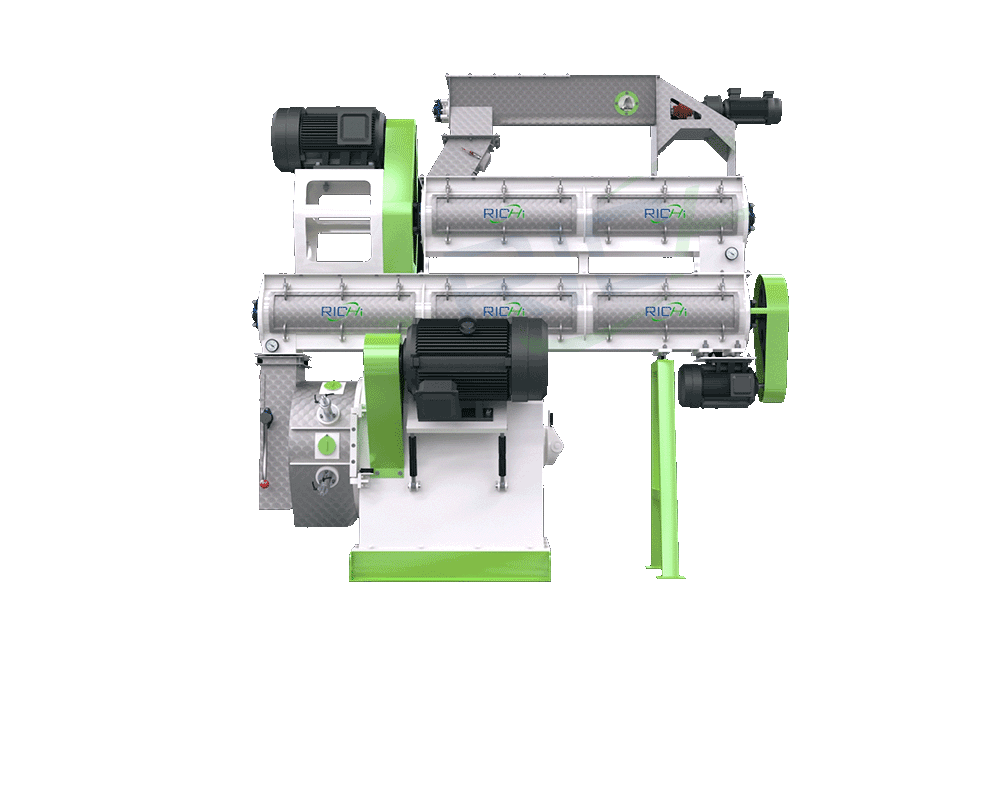

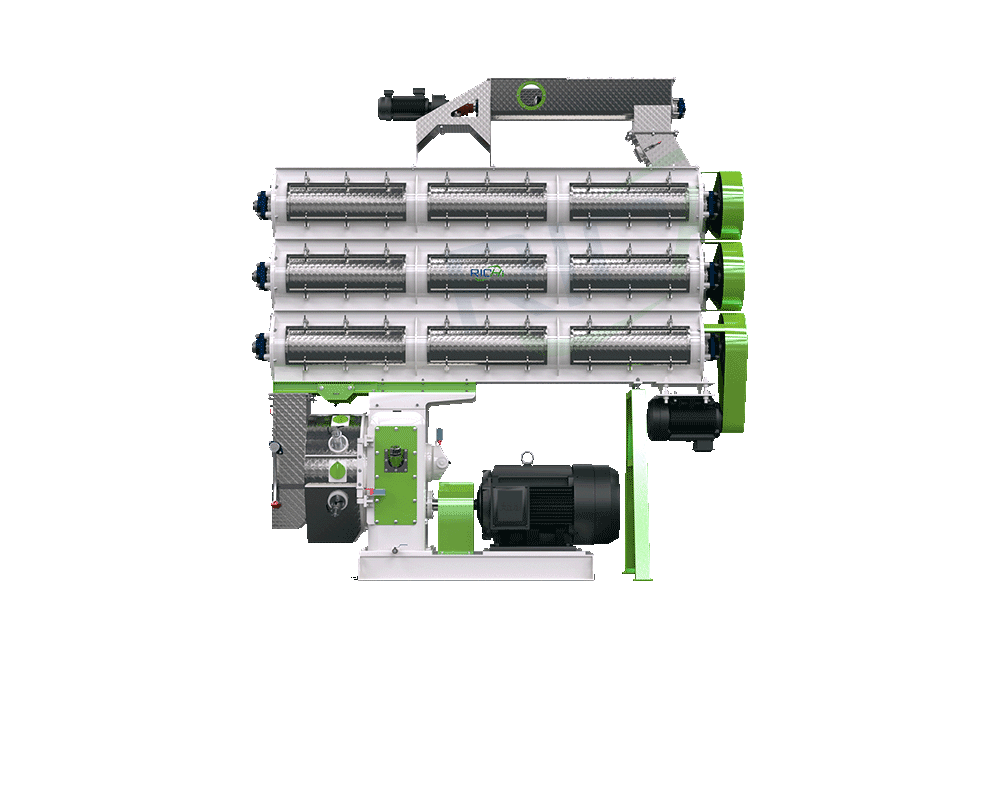

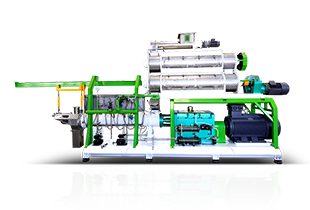

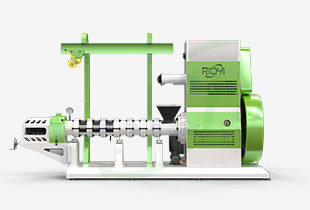

From raw materials to pellets, the pelleting step is crucial. Pellet hardness, size, and nutrient retention all depend on the performance of the pelleting equipment.

In RICHI, we have been focusing on making aquatic feed pellet equipment for many years, knowing that every equipment is related to aquaculture benefits. Whether you’re looking for high production capacity or a more refined pellet shape, we can provide you with the right equipment for a stable and efficient pelleting process.

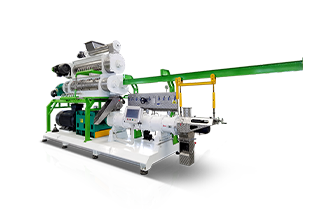

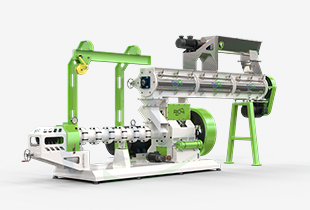

Tailored Aquatic Feed Production Line

Our aquatic feed production line solutions are tailored to the growth characteristics and nutritional needs fish, shrimp, and other aquatic animals. Also, we offer extended solutions for pet food production line and multi-functional feed production line.

They can flexibly adapt to the customization demand of medium-sized farms and the mass production target of large-scale breeding bases.

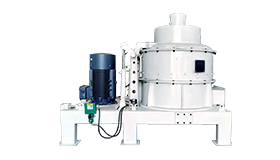

Auxiliary Equipment

Auxiliary equipment looks unremarkable, but it supports feed pellet machine/extruder keeps the entire production line running. Conveyor feeds materials to mixer, cooler shapes hot pellets, screener eliminates unqualified scraps, and packer seal the end product—each step interdependent.

These links are indispensable. They work together with main pellet equipment to ensure the efficient operation of the entire production process and the quality of the final product.

Global Market

After decades of development, RICHI’s footprints have spread across over 140 countries and regions worldwide. It has consistently provided stable and reliable equipment and services to customers in various everywhere, winning wide recognition.

North America

South America

Europe

Africa

Asia

Central Asia

Who We Are

RICHI Machinery is an industrial and trading company, covering the entire chain of equipment production, R&D, sales, and service. The company is deeply committed to innovation and development in the field of pellet machines. And its main products include animal feed pellet machines, biomass pellet machines, organic fertilizer machines, and aquatic (fish/shrimp/crab) feed pellet machines, which are widely used in agriculture, animal husbandry, and fisheries.

After years of technological accumulation and market expansion, the company has become more and more sophisticated on the road of integration of innovative design and industrial manufacturing. Today, our presence spans six continents, having successfully delivered thousands of projects for clients in over 140 countries.

At RICHI, the belief that “your future is our future” has never wavered. From your initial consultation to final project delivery, we always take this belief as the guide, so that you can feel the seamless and intimate service in every link.

140+

Exporting Countries

1000+

Successful Cases

60000㎡+

Factory area

Owner Support

Equipment Manufacturing

and Customization

Whether you are a new feed factory or want to upgrade and expand production, we have corresponding solutions. In terms of equipment, we have many types, and each type has many models. We can customize equipment based on your actual production needs, such as output and voltage requirements. Even if you want to expand and upgrade later, it won’t be troublesome at all, because all the production lines are modular in design.

Overall Solution Design

We don’t just sell equipment, but also pay attention to tailor-made a set of feed factory solutions for you. From small production lines of 500 kg/h to a standard production line of more than 10 tons, we’ll design solutions based on your budget, raw material characteristics, and finished product requirements. Whether you’re producing dry or wet pellets, floating or sinking feed, our technology can cover.

Installation, Commissioning and Training

Don’t worry about not knowing how to use it. We will arrange detailed installation guidance and operation training for each customer, either through remote video teaching or by sending engineers to provide on-site service, ensuring that the equipment can be put into production quickly and operate stably upon arrival.

After-Sales Service and Technical Support

We promise that all our equipment has a warranty, and we offer a long-term supply of common accessories and wearing parts. Our technical team is quickly responsive online, so if you have any questions, please feel free to ask us.

Overseas Services and Cooperation

We’ve been exporting for years, serving clients across Southeast Asia, Africa, the Middle East, Latin America, Europe, and beyond. Regardless of your country or region, we can assist you with export paperwork. Plus, we provide multilingual technical guides to make communication easy. From equipment delivery to factory setup, we’ll guide you every step of the way.